Leading Automatic Shrink Wrap Machine Manufacturer in china

JOCHAMP is a professional manufacturer of shrink-wrapping machines used for sealing and forming cartons. It has a maximum opening speed for a vertical opening mode that reaches up to 12 boxes per minute.

- Provide high efficiency and easy to use

- Offers a visible window, control display, and visible shrinking

- Provide remarkable performance

- Widely used for industrial packaging application

JOCHAMP Automatic Shrink Wrap Machine

JOCHAMP is a leading provider of automatic shrink wrapping machines designed to match industrial applications’ requirements. The automatic shrink machines can work stably for different sizes, fan speeds,s, and working speeds. It is also can be customized to fit production requirements. Our automatic shrink wrapping machines are suitable for the industry of pharmacy, stationery, gifts, food and beverages, and more.

We manufactured automatic shrink wrapping machines for more than 15 years with ISO9001, SGS, CE, and cGMP, certified. JOCHAMP provide a cost-effective solution for the wrapping industry, and also offers free sample test, one-year quality assurance, and lifetime after-sales service.

Message us now!

Multiply Shrink Wrap Machines For Your Choose

Jochamp Shrink Wrap Machine Sample Package (6)

Automatic Shrink Wrap Machine Advantages

Our automatic shrink wrapping machines will save you more time packaging your products than manual packaging. It has fully automatic functions that are easy to use.

We have a wide range of automatic shrink wrapping machines that are efficient, fast speed, convenient to use, and accurate to ensure high productivity in your business.

JOCHAMP manufactured automatic shrink wrap machines that are integrated with PLC control to ensure faster packaging of bulk products. It has an adjustable setting to set.

We are integrated with an expert quality control team to ensure high-quality automatic shrink wrap machines. We have in-house testing machines and raw material inspection.

JOCHAMP MACHINERY- China Leading Automatic Shrink Wrap Machine Manufacturer

- 2 years warranty support

- Speed has increased by 2-10 times and saved 10+ labor costs.

- Adopt Japan’s advanced technology and rich experience

- Supply 500 sets of high-speed shrink wrap packaging machines to the world every year.

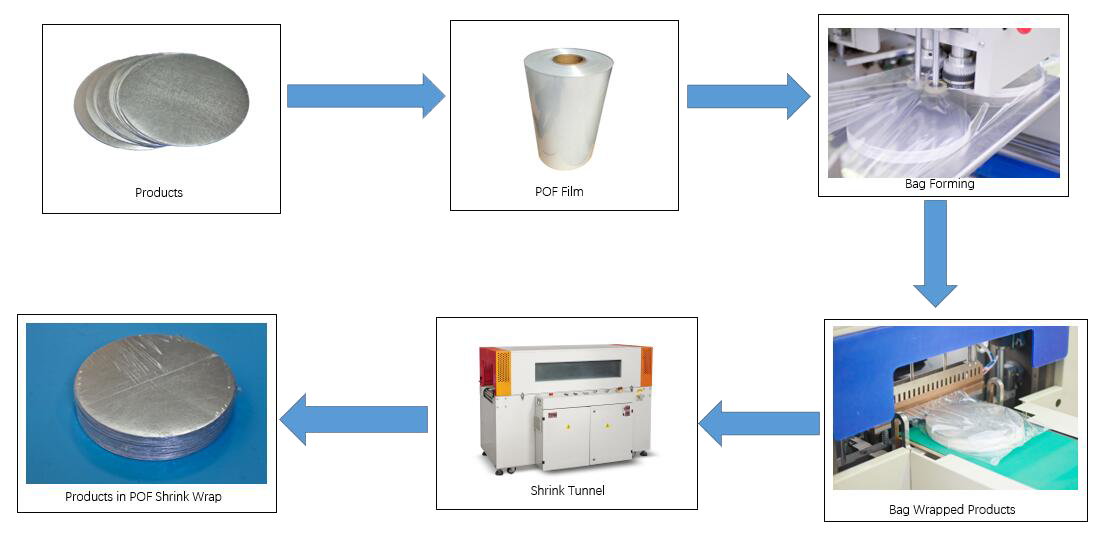

Jochamp Automatic Shrink Wrapper Manufacturing Process

What is Automatic Shrink Wrap Machines?

The automatic shrink wrap machines detect a product, seal, and shrink without the need for human operation. Automated machines have exit conveyors and infeed which need to be unloaded and loaded as the line is in process. The “automatic shrink wrap machine” term is a general means that can refer to many different functions and styles of devices. Some of the more popular automatic shrink wrap machines include Auto L bar sealers, Auto Bundlers, and Auto Side Sealers.

JOCHAMP provides excellent quality and competitive price of automatic shrink wrap machines with the help of advanced heat-shrinkable furnace control system temperature that helps save electricity consumption.

Send us your inquiry now!

Benefits When Using Automatic Shrink Wrap Machines

As a manufacturer, we make sure the quality of our automatic shrink wrap machine offers a lot of benefits including:

- Minimal Graphics Distortion. The automatic shrink wrap machines have heat tunnel technology that we deliver to make sure a tighter and more appealing wrap.

- Quick Changeover. It has a quick changeover in infeed rails and multi-lane conveyors to help for fast and repeatable changeover that offers multiple enhancements.

- Multi-Stream Capability. Our automatic shrink wrap machines are capable of multi-stream productions and can allow running two or three lanes at a time.

- Flexible Meeting and Collating. It has a metering technology that can handle bottles, jars, cartons, cans, hi-cone packs, and many more.

Automatic Shrink Wrap Machines Applications

JOCHAMP automatic shrink wrap machines are tightly applied to fit a product using a heat source to cover the particular dimension and wrap the products. Below is the following application of the automatic shrink wrap machine:

- To secure large pallet loads

- Tamper evident sealing

- Combination packaging

- Sampling and promotional packaging

- Securing boxes

- Provide additional product protections

- Utilizing beverages and canned goods

JOCHAMP – Trusted Automatic Shrink Wrap Machines Supplier

As a trusted supplier, we always ensure that our automatic shrink wrap machines can offer high-performance, maximize ease of operations, long-life service, and durability with excellent quality and competitive price. The automatic shrink wrap machines can feed, sealing, shrink and transport products.

Our automatic shrink wrap machine offers high efficiency in sealing and shrink wrapping different products. It is suitable for shrink wrapping products with different sizes, widths, heights, and dimensions. These automatic machines can perform clean and tidy wrapping. We can customize automatic shrink wrap machines based on your requirements. Just send us your specific details.

Send us your inquiries today!

We provide an automatic shrink wrap machine that offers different features such as:

- Anti-cutting device

- Human+Machine Operator

- Has a stainless steel heating tube

- Electricity and device energy savings

- Easy to operate and maintain

- Well equipped with a PLC control system

- Has a safety protecting alarm devices

- Can automatically adjust the length of shrink film

- Anti-stick and high-temperature resistant

- Suitable for shrink thin and small products

Using our automatic shrink wrap machine can provide a lot of advantages including:

- Faster wrap times

- Reduced operator fatigue

- Consistent load quality

- Reduced material cost and labor

- Improve load integrity

- Provide tremendous benefits and substantial cost saving.

Why Choose JOCHAMP Automatic Shrink Wrap Machine

The automatic shrink wrap machine can provide fast due to the motion required to make a seal. It can run for 80 up to 220 products per minute and can wrap for almost 50 thousand products daily.

By the use of our automatic shrink wrap machines, it can wrap different sizes from small to large per day. Here in JOCHAMP, we provide automatic shrink machines with different sizing options to cater to different types of products. This machine can pack food and non-food products.

Our shrink wrap machines are suitable for different centerfold shrink films. These are also suitable for films made from different materials including polyolefin, PVC, and more with different thicknesses ranging from 45 to 100 gauge.

Our automatic shrink wrapping machines are manufactured with wire sealing blades to provide repeatable sealing. These are ideally suitable for wrapping with products thick films. After sealing, the packed products are transported by the use of a conveyor.

- Jochamp Shrink Wrap Machine Factory Tour

of course, we can design, manufacture and install automated packaging lines based on customers’ products, budgets, factory floor plans, etc.

Unlike the standard machine, if the machine involves customization, the price will be different. So before getting the final quotation, you need to provide exact product information, speed requirements, etc.

Single-layer POF shrink film thickness 0.015mm=15 micron (Only mosquito coils need to use PVC shrink film because the chemicals in the mosquito coils will react with POF)

It can be used, but due to the shrinkage characteristics, it is not recommended to use a film with too high printing fineness.

It is possible but not recommended. The packaging effect of PE film is too poor, and the material will be sticky.

Film width = (product height + product width) x2 +100mm

The linear speed of the machine is 32 meters/min, and the speed generally converted into a product is approximately equal to 80-130pcs/min.

It is mainly reflected in the different operating modes of the horizontal sealing knife.

The 590’s horizontal sealing knife is a way of rotating.

The 500 horizontal sealing knife is a reciprocating operation.

In comparison, the biggest difference is that 500 is more adaptable.

The size range is similar and does not exceed the adjustable range of the machine, then your products can use one machine to pack them.

If your product size is too different, then it is recommended that you use multiple devices.

Automatic Shrink Wrap Machine: The Ultimate Guide

Shrink wrapping is the process of using heat to aid in wrapping items using a heat shrinkable material film.

A shrink wrap machine is responsible for shrink wrapping products using heat shrinkable films that take the shape of the items.

shrink wrap machine

Before choosing any automatic shrink wrap machine, consider the factors below.

Type Of Product Your Company Works With

Product type usually determines the automatic shrink wrap machine to used.

Features such as display, protection, storage, bundling and tamper resistance are to be considered.

Dimensions Of Product

For a fully automatic shrink wrap machine, product length has no limit, but the height and width have limits.

Therefore, choosing the right machine for your product dimensions is necessary.

Orientation Of Packaging

Packaging orientation is usually determined the kind of style or outlook the package is required to display.

Choice of packaging orientation will determine the type of machine to go for.

Production Output

To choose the right automatic shrink wrap machine, get to know the capacity of your production.

Capacity varies from high, medium to low and is measured in packages per minute.

Shrink Film Material

There are various shrink film materials that can be used with automatic shrink wrap machines including POF and PVC.

Ensure that the machine of choice works well with the material.

Extra Features

Automatic packing machines can have other machine features incorporated within them such as labelling and checkweigher features.

Choosing an automatic shrink wrap machine, may require you to consider such requirements.

Machine Speed

High production of products will require a packaging machine with high capacity that can work at a high speed.

A high-speed machine produces approximately 30 to 80 packages per minute.

Automatic Shrink Wrap Machine

Automatic shrink wrap machine uses a shrink film material and wraps it around a product through the use of heat.

Shrink wrap machine produces a package which is in the shape of the product being wrapped.

Advantages of automatic shrink wrap machine include cost-effectiveness, touch screen, printing and high speed.

Applications of an automatic shrink wrap machine include pharmaceutical, food, cosmetic, chemical, beverage and detergents industries.

Overwrapping Machine

Overwrapping machine works by taking a film which is heat sealable from a roll and wraps it a round a product.

Sealing is achieved through heat sealing devices and the wrapping film does not take the shape of the product.

Some of the advantages of an overwrapping machine include excellent appearance, easy opening, no heat needed, efficiency and flexibility.

Overwrapping machines can be used in industries like tea and coffee, cosmetics, pharmaceutical, paperware etc.

High Speed Automatic Shrink Wrap Machine

High speed automatic shrink wrap machine can automatically form bags and create a heat shrink wrap film around them.

The resulting package is secure, uniform and with an excellent aesthetic appearance.

Products like picture frames, rolls of thread, food trays and machine parts can be packed, and shrink wrapped using this machine.

high speed automatic shrink wrap machine

High speed automatic shrink wrap machine consists of features like automated feeding system, full closer packages, PLC, sensors and error detection.

Automatic L Sealer Shrink Wrapping Machine

Automatic L sealer shrink wrap machine consists of a pair of sealing bars taking the shape of a backwards L.

Film used for shrink wrapping is folded creating a pocket along the bars through the fold crease.

Through the crease created, the products can be placed into the wrap while the remaining three sides of the film undergo sealing.

Automatic L sealer shrink wrapping machine

From the sealing station, the product is moved to the heating station for tightening of the wrapping film around the product.

Automatic Side Seal Shrink Wrappers

In automatic side seal shrink wrap machine, the shrink machine is fed in through a reel around the item.

The film forms a loose tube-like shape along the length of the product followed by sealing.

The package is then moved to the heat-sealing station to shrink and tighten covering around the products.

Automatic side seal shrink wrapper

Automatic side seal shrink wrap machines are capable of handling products of any length and size.

Automatic Sleeve Sealing Shrink Wrapping Machine

Automatic sleeve sealing shrink wrapping machine uses reel of shrink film which is stretched and cut and then applied around items.

This wrap will produce a thick and heavy-duty plastic covering around items after being sealed and shrunk through heating.

automatic sleeve sealing shrink wrap machine

Products in multiple packs or heavy items require this kind of a wrap for protection and security

Generally, the machine is used when handling products that prioritize protection over aesthetic appearance.

Automatic sleeve sealing shrink wrapping is used when handling larger objects.

Inline Automatic Shrink Wrap Machine.

Inline automatic shrink wrap machines are designed to offer a shrink wrap around products that are longer in length.

Belt-to-belt transfers are incorporated into the design and they can be used at the end of every production line.

inline automatic shrink wrap machine

Such machines are suitable for all products with no limitation to product type from trays to hardware products.

PVC) Polyvinyl Chloride Shrink Film

Polyvinyl Chloride is an inexpensive and lightweight plastic shrink film which is durable and can be used for various applications.

Some of the applications for polyvinyl chloride shrink film include construction products, household products, gaming and other non-consumable products.

One outstanding limitation of PVC is that it produces fumes when heated and must be used in a well-ventilated work area.

Polyolefin (POF) Shrink Film

Polyolefin is described as a very versatile and extremely durable and best shrink wrap.

POF can offer features like cross linking wraps with high clarity and tensile strength.

Companies that run high speed machines and operations prefer to use polyolefin as the shrink wrap film.

Another advantage is that there is no build up of sealing components on the machinery.

Polyethylene (PE) Shrink Film

PE material offers more strength and durability and can be used for products that are in bundles and are heavier.

Such items include packs of beverages, chemicals, drugs, doors, spare parts, window frames and glass jars.

Polyethylene material can be printed and still maintain the kind of strength as needed.

When these three materials are compared, PE is the cheapest.

Several Runs With Few Types Of Products

Automatic packaging machines work perfectly well when dealing with one type of a product which is needed in high volume.

A particular setting or parameter is instructed on the touch screen HMI and runs for a long period of time.

Efficiency Needs

Human labor is costly and slow, and in order to increase the speed of production and cut on costs, you need a fully automatic machine.

Automatic shrink wrap machine is efficient and eliminates human labor hence reducing on operational costs.

Consistency Requirements

A production line that involves the use of human input at certain stages of production, cannot achieve consistency and repeatability.

An automatic shrink wrap machine is accurate and precise and can produce products that have the same features and dimensions.

Multiple Performance

With an automatic packaging machine, you can get all the functions done by the same machine in one run or cycle.

Some of these functions include loading material, making of trays, packing products, wrapping the products and labeling the wrap.

Food Industry

Automatic shrink wrap machine can be used for packing and wrapping products like Fresh food, processed food, dairy, beverages, confectionery.

Consumer Goods Industry

Consumer goods manufacturers require the use of an automatic packing machine for packing Gifts, household products, toys and gaming products.

Cosmetics Industry

In the cosmetics industry, Hair products, make up products, body products, make up kits and other personal-care products are packed.

Pharmaceutical Industry

A shrink wrap machine offers protections and ensures the integrity of products like Drugs, chemicals, detergents, medical devices and equipment.

Construction Industry

Spare parts, cement, doors, window frames, paints and other construction products are safe and secure when packed through this machine.

Electrical and Electronic

Cables, phones, computers are some of the products within this industry that get noticed because of the wrapping style used.

Automatic Shrink Wrap Machine

Automatic shrink wrap machine has all functions incorporated within one production line eliminating human labor.

Functions such as material loading, tray making, product loading, product packing, sealing, wrapping and labeling are done with one operation.

An automatic shrink wrap machine can handle high production speeds with high capacity leading to high production output.

automatic shrink wrap machine

Some of its features include inline layout, HMI, can handle most products and work with any film material.

Semi-Automatic Shrink wrap Machine

Semi-automatic shrink wrap machine has its shrinking and sealing cycles separated to enhance speed of operation.

For this machine, certain operations like product packing and material loading are done by the operator.

semi automatic shrink wrap machine

This shows that not all the functions are automated making it slower compared to an automatic shrink wrap machine.

Some of its features include pneumatically controlled film tension, seal jaws are independent, human machine interface, and independent electrical cabinet.

Automatic sleeve wrapping machine is the equipment put together to produce a thick and heavy-duty plastic covering around products.

When protection is far much important than appearance or aesthetics, this is the machine to go for.

The machine works by wrapping a heavy-duty polythene around the item, the wrap is then heated and cooled for tightening

Automatic sleeve wrapping is usually meant for larger objects.

Manual Shrink Wrap Machine

A manual shrink wrap machine is made up of a sealing bar, film dispenser, and a heat gun which is operated manually.

Through a reel, the film is fed on the flat working surface, the product is then manually placed on to the film.

Another film is placed onto the product then the leaves of the two films are sealed together through a hot sealing bar.

manual shrink wrap machine

Film shrinks to the surface of the product through a heat gun.

Manual shrink wrap machine is very limited in terms of output even though the cost is very low.

Such machines can be used by small businesses dealing with small and solid products.

Automatic Shrink Wrap Machine

Automatic shrink wrap machine is a more complex machine with every level of operation automated.

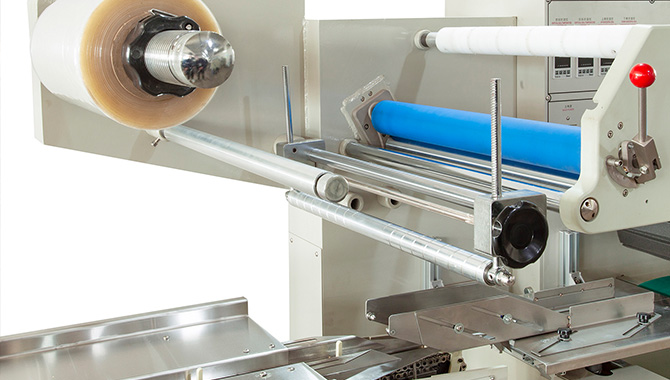

Form material and product feed through a feeding system aided by rollers and film dispensers.

The machine is able to wrap the film around the product automatically and sealing is also done automatically.

After sealing, conveyer belts move the product into the heating station to tighten the wrap.

After tightening the wrap, through the conveyer belt, the product moves to the labelling station.

Automatic shrink wrap machine is required for companies that deal with high throughput productions and can handle any kind of product.

HMI Touch Screen

Human machine interface with a touch screen is used for control and monitoring of the whole shrink-wrapping process.

Conveyer Belts

Conveyer belts, controlled through electric motor system, are responsible for the movement of the product from one station to the next.

Entrance Table

Entrance table offers a surface for the application of shrink film to wrap the product all round before being heat shrunk.

Sealing Head

Sealing jaws are responsible for sealing the loose shrink film flaps to cover the surface of the product.

Film Feeder

Film feeder is the component used for feeding shrink film material into the machine system and wrapping it on the product.

Retraction Channel

Retraction channel is used to control the air pressure within the system to ensure that the shrink wrap has no impurities.

Heat Shrinking Station

Heat shrinking station is designed with a heating system used for shrinking the film to create tighter covers.

Automatic shrink wrap machine functions by dispensing the shrink film to loosely cover the product through the film feeder.

After loosely covering the product, the sealing head which is heated aids in sealing the flaps together.

Through the conveyer belts or rollers, the wrapped product moves to the heat shrinking station where appropriate amount of heat is applied to shrink the film.

The heat shrinking film sticks to the surface of the product on cooling to form a tight and strong cover.

From the heat shrinking station, the product is moved to the labelling station before being dispensed in readiness for distribution.

Automatic Stretch Wrap Machine

Automatic stretch wrap machine is used for wrapping products to a pellet using a much thicker film.

Shrink material film used in automatic stretch wrap machine is very flexible and before the application, it is usually pre-stretched.

An automatic stretch wrap machine produces packages that are tighter and clearer compared to other machines.

automatic stretch wrap machine

The machine is mostly required when wrapping products that are getting ready for transportation due to the much thicker wrap.

Automatic Shrink Wrap Machine

Automatic shrink wrap machine uses a shrink wrap film material and wraps it around a product by applying heat.

Shrink wrap machine produces a package which takes the shape of the package or product being wrapped.

After wrapping, the surface can still accommodate labelling depending on the companies requirements.

Any wrap film material can work with an automatic shrink wrap machine to produce a strong and durable package.

An automatic shrink wrap machine can be used with any kind of product whether it is being stored or transported.

Incorporating features such as labeling and weigh checkers in the same production line may aid in increasing machine efficiency.

The PLC control system is simple and easy to use saving on time and increasing output.

Design the machine with an easy and simple changeover procedure to save on time and reduce machine down time.

Go for machine design which is versatile and can handle all types of film materials and products.

Machine maintenance is important to prevent loss of equipment and failure of the machine, prolong machine life and prevent product contamination.

Lubricate Parts

Lubrication is necessary, especially for the moving parts of a shrink wrap machine, to achieve a smooth and frictionless work process.

Cleaning Parts

Regular cleaning and maintenance of parts is recommended and this can be done by following the manufacture’s guide on cleaning.

Regularly Oil The Reducer

The reducer cannot work without oil, it is therefore important to clean it and replace oil every 2500 hours of work.

Handling The Machine

Machine is not to be impacted or tilted or tipped down during handling.

A grounding device should be used during installation.

Regular Inspection

Apart from regular cleaning and lubrication, the machine parts must also be inspected to make sure they are in good condition.

Power Value

While the machine is in operation, ensure that the nameplate power indications is less or equal to the input power.

This will ensure that the machine parts or the internal circuits are not burnt.

Power And Ventilation

When operating the machine, ensure that the work environment is ventilated before switching the machine on.

Also, before putting the power off, ensure that the gas system is cut off.

Working Conditions

Surrounding environment should be at temperatures of -10°C to 50°C with humidity of not more than 85%.

Ensure there is no dust, corrosive gas or explosive products in the surrounding.

For all your automatic shrink wrap machine, contact us now.