1. Advantages of horizontal packaging machines

This is an automated machine that produces a hermetically sealed cooker from the film. It folds to poach, automatically fills the product, and seals it. Wet as well as dry ingredients can be used in this poaching. The packaging process is the last step in the production line.

Many companies prefer to add horizontal packaging to their product range. This is because of its advantages, listed below.

- Helps in a faster and cheaper production process as it covers all stages of production automatically. This makes the entire packaging process faster.

- This is a flexible packaging solution. No problems filling and sealing solids, liquids, or dry products.

- With this type of packaging, more surface area is available for graphics and written messages.

- Protect cargo from damage, dust and moisture. It reliably ensures product hygiene by eliminating hand contact with food and pharmaceuticals.

The machine is equipped with a safety device, which will stop immediately after detecting abnormal air pressure and heater disconnection alarm.

- It improves inventory because it stacks similar products together. This reduces product separation, which can make counting time-consuming.

- The machine is easy to operate, clean, easy to maintain, and user-friendly. With automatic detection function.

- The machine provides consistent pharmaceutical packaging solutions that are relevant for the export of goods.

2. Disadvantages of horizontal packaging machines

Just like any other machine, this one has some limitations that may prevent it from being used. They include:

- Some brands have limited capacity.

- Even automatic horizontal packaging machines require operators. For semi-automated robots, their workload is even greater.

- To be flexible, it must compromise in at least one key area. These areas include performance, speed, price, conversion time/consistency, memory footprint or complexity.

The operation of this machine requires discipline. It requires mechanical and electronic adjustments to establish the centerline required to run a specific product.

3. Vertical Packaging Machine vs Horizontal Packaging Machine – A Final Comparison

The vertical packaging machine and the horizontal packaging machine have more similarities than differences. These can be seen in their operations, the products they package, specifications and considerations when purchasing.

However, there are some differences between the two machines. So, in this thread, I want you to see the final comparison of the two. This will involve design and construction, advantages and limitations.

1) Mechanical Design and Construction

Vertical and horizontal packaging machines operate differently. Horizontal machines take a roll of film and run it over a plough to create the bottom of the gusset. As a result, the film does not have to be pulled through the machine with as much force. On the other hand, a vertically oriented aircraft uses more force than a vertically oriented aircraft. This is because the film roll is unwound in an upward direction.

2) Film Folding

The film of the horizontal machine is folded flat in only two dimensions after moving on the plowing surface of the machine. In addition to this, the film can also run past subsequent sealing stations. This can allow it to be preheated, heated and cooled in a series of indexing cycles.

In a vertical packaging machine, seal production and bagging are carried out simultaneously. Any further preheating, heating and cooling depends on the time in a single cycle. This may result in a less refined look that may not be up to your approval.

3) Product Filling Process

The horizontal machine fills the product through the top into the film while the bag is pulled open. It has a full bottom gusset. When in use, this provides 100% fill capacity. Most horizontal bags are either ⅔ to three-quarters full. With vertical packaging machines, this filling is difficult to achieve. This is because the bag is formed while filling through both sides of the bag. Here the gussets are not fully opened; therefore, the capacity of the bag is not appropriate.

4) The benefits of machines

Because only one person operates the machine, it is not only cheap but also reduces labour costs and speeds up the production process. Both protect the product from damage, contamination, dust, or moisture because the packaging is reliable with less human contact. Inventory has improved as packaged products stick together.

This makes counting easier and less time-consuming. Additionally, these machines are user-friendly, making them easier to use once the orientation is established. Also, they are easy to clean and maintain. Both vertical and horizontal packaging machines have automatic inspection functions.

They can detect if a package is present, open or closed. This reduces bag or material waste. In addition, these packaging machines use safety devices. When they detect any abnormal air pressure, a heater disconnects alarm sounds to notify operators.

For both, the wrappers are consistent. This is very useful for products exported to other countries. In both machines, human contact with the product is minimized during the packaging process. Therefore, environmental pollution and its impact on human health are reduced.

5) Machine limitations

Vertical packaging machines cannot use hard materials such as paper, poly or foil because it uses more force than horizontal packaging counterparts. On the other hand, single-layer linear PE films cannot be run on horizontal packaging machines.

They all have limited production capacity, which may differ from individual machines. Neither machine can operate independently without an operator. Someone has to get it up and running. Some of these machines make compromises in key areas such as speed for flexibility.

Both machines require operational discipline, as most products have their own centerlines to adjust. Failure to do so may result in a loss of efficiency in the packaging process.

4. Application of Horizontal Packaging Machine

Many businesses rely on these machines to package products in both solid and liquid form. These applications include:

1) Food processing industry

The company produces egg dry-fried standard dry and stuffed pasta packaged using this application. Bakeries use it to package bread, cakes, pizza, breadsticks, cookies and crumbs. It is used to package beverages such as milk, water, alcoholic and non-alcoholic beverages.

This machine provides reliable standard bags with all aspects of sealing. This method is also used in the packaging of candy, chewing gum, toffee and bubble gum. It is also used to package wet and dry pet food and dental.

2) Cosmetics industry

Wipes to clean cosmetics, babies, refreshing and cleaning pets use this application.

3) Pharmaceutical Industry

They use it to wrap gauze bandages, syringes, blisters and drops.

4) Agribusiness

The packaging of seeds and chemicals also relies on horizontal packaging machines.

5. Horizontal Packaging Machine Parts

The horizontal packaging machine consists of many parts. These components have functions that enable the device to perform its functions efficiently. They include:

- Feed Link/Infeed Conveyor: This part uses 304 stainless steel powder injection codes to help package products in a safe and hygienic manner.

- Pull Membrane Structure / Membrane Former: Here we have a multi-link membrane to coordinate the pull membrane. It also enables the smooth rolling of the film.

- Encoder: This part of the machine uses a ribbon printer to print the date, logo or any desired text on the packaging. It can position the print more clearly and accurately.

- Smart Touch Screen: This is a colour touch screen that helps to set parameters before the machine can be used.

- Automatic sealing: Rotate the hot air incision before and after packaging to ensure both ends are properly sealed.

- Finished Product Delivery/Product Unloading Area: This is where packaged products are unloaded when they are ready to be packaged into cartons.

6. Working principle of horizontal packaging machine

It has a feed conveyor, a membrane supply assembly called the back stent and a membrane formation zone called the anterior membrane. It also has a bottom seal sometimes called a fin seal, a cutting head, and a discharge area.

The food and non-food products produced during the production process are placed on the infeed conveyor of the flow packer. You can manually or use an automatic feeder solution. The conveyor transports the product to the forming area.

The film is drawn from the film supply assembly to the forming zone. This part forms the film tube around the product and creates a fin seal. Then send it to the cutting head. This cutting head creates an end seal, while the sections it cuts are packed into individual packets adjacent to each other. The sealed package is moved to the unloading area, where it can be boxed. The following illustrates how horizontal packaging is completed.

7. Considerations For Buying Horizontal Packaging Machine

When you want to buy this machine, you have to consider a lot of factors. Let’s see how the following factors affect the choice of machine.

1) Model or brand

There are many models and brands of horizontal packaging machines. Some models use 4 servo motors to enable quick and easy switching and adjustment. In the production process, the loss of films and products is reduced, and the maintenance is convenient.

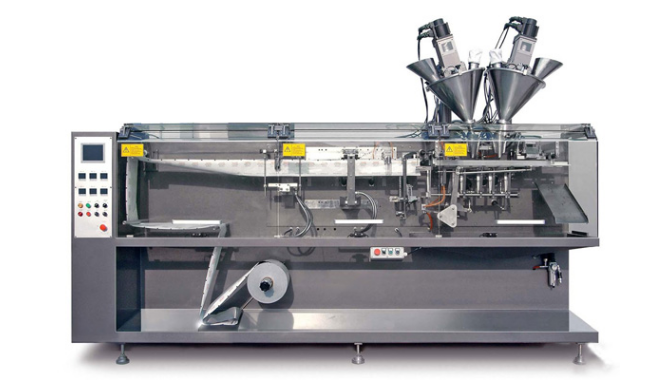

Servo drives help ensure precise positioning, smooth acceleration and deceleration. This also comes standard with pre-programmed store product settings and stainless steel frame construction. The picture below shows one of the models of horizontal packaging machines.

There are also those that use 5 servo motors to create quick and easy switching and adjustments. Keep in mind that there are also brands that combine the features of horizontal and vertical packers in one advanced new compact packer.

This type of packaging machine is the latest and can be used in many applications. Additionally, the vertical position is ideal for automatic bagging and product loading machines. There are trays and containers in the horizontal position. Some have length detection sensors and operation logic. This can be used to adjust the length of the product at each cycle. This adjustment can make the bag according to the length of the product.

2) Specific Application

The choice of correct horizontal packer will also depend on the task you want it to perform. For example, some machines are more suitable for packaging small products, but cannot effectively package large products.

3) Technical Specifications

Vertical packaging machines come in a variety of styles with different technical specifications. For example, some products have higher power consumption and are only preferable when required by the production level and product type.

4) Type of Horizontal packing machine

Choosing these machines can be tricky because there are so many things to consider. To make the best choice, evaluate technical capabilities, labour requirements, worker safety, and maintainability. Also, look at serviceability, reliability, and the ability to integrate into packaging lines.

In addition, capital cost, floor space and conversion, materials and flexibility of multiple products must be considered. Finally, you must consider energy requirements, the quality of the outer packaging, and the eligibility of food and medicines.

Horizontal packaging machines fall into two categories. They are:

Semi-automatic horizontal packaging machine

This machine can be used to pack multiple products in small batches with variable pack sizes. It is suitable for the packaging of sandwich and non-laminated prefabricated bags. It is suitable for filling and sealing non-free-flowing powder chemicals, pharmaceutical powders, food, beverages, cosmetics and other materials.

For precision, the powder is filled with a PLC-based controller with built-in pulses. Helical rotation pulses are modified and adjustable through a touch screen system for accurate weight compensation.

Automatic horizontal packaging machine

The machine grips a pre-formed bag fills it with the product and seals it. The rate of this process is between 40 and 200 bags per minute. It has a positioned circular layer where the bag is moved intermittently to different positions.

Each station performs a different packaging function. There are usually 6 to 10 sites, but the most common configuration is 8. The automatic bagging machine can be designed as a single row, double row or quad row. So let’s look at these monitoring stations in more detail.

- Package loading

The operator manually loads the preformed bags into the bag holder in front of the automatic bag sealer. A bag feeder then delivers the bags to the machine. This machine has a robot that feeds bags with a vacuum, grabs individual bags, and loads them into the bag grabbing area.

- Bag Complaining

This has a proximity sensor to detect the bag, after which the vacuum bag loader picks up the bag. It then transfers the bag to different grippers that hold the bag as it moves to different positions along with the swivel

- Printing/embossing

If this is required, the machine will go through thermal printers and inkjet printers. Printing allows data and lot numbers to be affixed to the bag.

Opening and inspection of zippers/bags

The bag with the zippered shell is opened by a vacuum suction cup which opens the lower part of the preformed bag. Open the pliers by grasping the top of the bag to open it.

This is inflated by separating the top of the bag opens outwards using a blower. There are two sensors on the bottom of the bag that help detect its presence. If not detected, neither the filling station nor the sealing station is involved in the packaging process. If the bag is detected but not placed correctly, it will not be filled and sealed.

- Bag filling

The product descends into the funnel into the bag using a multi-headed scaly spiral filler. For liquids, the product is pumped into the bag through a nozzle. Filling equipment is responsible for correctly measuring and releasing discrete quantities of dripped products.

- Product settings and other options

At this stop, you have to make sure that the loose contents are sealed before the bottom of the bag. To do this, shake the pre-made bag well. Other options for this station include secondary sealing fluids to provide maximum seal integrity.

- Seal bag, deflate

With two pressure reliefs, the seal is complete before squeezing out the bag’s remaining air. After that, the heat seal is closed on the upper part of the bag. Using heat pressing, the preformed pouches are layered with sealant and then glued together to make a strong seal.

- Cooling and draining

A cooling rod is then passed through the seal, making it firm and flat. The machine then places the finished bag into the container. Then it can be transported to other carton packers.

- Production Capacity

The production capacity of each machine varies from 40-200 units per minute. There are large capacity horizontal packaging machines like those used for cosmetic bags

- Power Consumption

Power consumption varies depending on the type of machine. The phase power consumption of horizontal packaging machines can range between 500W and 1KW. A bath soap bag machine consumes 2 kW.

- Quality compliance

This machine is manufactured under the supervision of experienced professionals using the highest quality components and according to quality standards set internationally. A good horizontal packaging machine should comply with CE, CCC, cGMP, RoHS and ISO standards.

A good machine should provide high performance and reliability. It should also be formed, filled and sealed in a single process. It is safe for the product and the user.

- Technology

The technology to make these machines has evolved to the high-speed performance that can run 24/7. Simple design, convenient operation and maintenance. The technology is widely accepted worldwide because it is accurate at the time of delivery.

- Dimension

This also varies from model to model. For example, there are some that measure 3990mm long x 1100mm wide x 1950mm high. Other sizes are l70 – 420xw140xh80mm and many others.

8. Conclusion

Horizontal packaging machines are very relevant to the safety and reliability of products on the market today. Many foods and non-food production companies have adopted this technology because of its cost-effectiveness.

This also provides maximum protection for their products. It can be used to package a wide variety of products, from small to large packages. Due to growing interest in this application, more efficient machines have been developed to limit human exposure to toxic products.