When it comes to purchasing packaging equipment for your production line, many factors you should consider. From investigating machinery makes, designs, as well as brand names to selecting a supplier for service, supply, and preventative upkeep. Getting product industrial packaging machines is a large investment for your company.

Machinery for Packaging Industry-Ultimate FAQ Guide

When thinking about the acquisition of brand-new packaging machinery, you will certainly wish to take the time to do your research and invest due diligence into the process. If you wish to know what sorts of equipment are offered, the materials they run, their correct and also risk-free operating treatments, as well as exactly how to maintain them running at peak performance, this guide will certainly provide you with all the information you are seeking and then some.

What is Packaging Equipment?

Packed machines are also called packaging machines or packing equipment. Packaging machines are utilized to package products or elements. This product location includes equipment that forms, fills, seals, covers, cleans up, as well as bundles at different degrees of automation. Packaging machines likewise include related equipment for sorting, counting, and collecting.

There are various package kinds. Instances include: spray can, bags as well as bags, blister packs, containers as well as jars, cartons and boxes, containers, pills, cartridges, situations, mugs and trays, drums, kegs and pails, pallets and intermediate bulk containers (IBC), tubes, and also vials. Closing methods for product packaging equipment can use caps as well as covers, cork, glue, warm seals, nails or staples, tamper-evident or tamper-resistant tape, tuck and also fold techniques, as well as covering paper.

Anyhow, a industrial packaging machines can be made use of to fill liquids, wrap products, weigh items, as well as secure items from transport as well as storage space.

History of packaging equipment

Packaging can be mapped back thousands of years. The very early days of the packaging had to be done by hand and was likely made from woods, skins, leaves, and other products of the kind. As time took place, product packaging was made with woven bags, baskets, straw, and also various other containers like ceramic.

In the 19th and 20th centuries, packaging machinery started ending up being extra widespread. New packaging types were invented such as bags, food packaging, storage space containers, and retail product packaging mainly made with paper. In 1894, Friedrich Hesser created the very first bag maker for packaging goods. And later in 1890, Michael Owens invented the first automatic rotating bottle-making machine which caused the glass container appeal from then on till the 1960s. In the very early 1900s, plastics were presented in the packaging sector. In 1906, one of the initial packaging machines was developed to accommodate the new material.

After the First World War, packaging machine manufacturers and inventors were busy developing new and effective product packaging methods. Consumers use a lot of packagings such as cardboard boxes and metal containers in their daily lives. Flexography was invented in the late 1920s, enabling businesses to publish extra precisely on their product packaging.

Product packaging technology ended up being so prominent that Michigan State University come to be the very first college in the world to use a level in Packaging Engineering in 1952. During this time around, breakthroughs in the pharmaceutical and also health and wellness industry started to make use of packaging machinery to be more effective to package their products.

Today, many product packaging equipments is automated for performance and also faster manufacturing times. These machines are managed by CAD and CNC makers to lower labour costs. A goal for the future is to find more lasting kinds of product packaging and also equipment.

Benefits of Using Industrial Packaging Machines

While it is practically feasible to run a packaging division practically specifically on human physical labour, most of the moment it is neither a great or appropriate service.

It holds true that packaging machinery includes a significant upfront financial cost, but the dividends that a quality packaging line with robust equipment can payout deserve their king’s ransom. Listed below, we will have a look at the many benefits of using product packaging equipment on your packaging line.

When it pertains to generating a multitude of top quality items, a robust product packaging line can make or damage a firm. This is especially real if you are generating a high quantity of products in a short quantity of time.

Sure, you can lean heavily on manual work, loading tables, cardboard boxes, tape, as well as hand film. That being stated, is it actually an audio investment if your volume is greater than your team can manage regularly?

Investing tens, hundreds, or sometimes millions, of dollars into industrial packaging machines can be daunting, yet the money that this machinery can save for your firm over the long term can make the financial investment worth it.

Furthermore, with financing and leasing choices, getting your hands on the packaging machines you need to take your manufacturing and also your firm to the next level is less complicated than it has ever before remained in the background of product packaging.

Overall Cost of for Packaging Machine

The overall cost of ownership is just one of the most essential characteristics to consider when you are considering your alternatives in regards to your product packaging division. With the ideal product packaging machinery, you will require a smaller labour force, consequently paying dramatically fewer earnings.

Without a doubt, industrial packaging machines can feature a fairly huge price, however, when you take the overall cost of possession of a semi or fully automated packaging line and compare it to a stockroom full of manual labourers, the numbers start to lean in the direction of machinery as the most practical choice for success.

Taking the time to contrast what you are spending for your labour force (not only in cash and also time yet likewise in regards to hiring, firing, unwell time, and holiday) to a mostly mechanized line may surprise you. Chances are, you may very well locate that actually, a machinery-driven product packaging line with a couple of well-trained and also committed operators is the far better choice both financially and also logistics-wise.

In other instances, you may discover that now is not the moment to look for the financial investment, but it’s worth reviewing regularly to make sure you are considering your general costs and your future service goals and also expectations.

Speed

industrial packaging machines allows you to package more products per hr than physical labor. When the speed at which your product enters the market is an important motivator for your company, it is very important to ensure that you are using packaging equipment instead of manual labor.

People cannot pack products as quickly and efficiently as automated or semi-automatic mechanical packaging lines.

Integrity

Product packaging equipment does not take sick, individual, or getaway time. While downtime might happen as a result of mechanical failing or a busted component, these issues are quickly treated and are scarce when you plan your downtime. Combining with a normal plan of preventive maintenance, the mechanical packaging line can save you thousands of dollars and time each year.

An Eye Towards The Future

As product packaging equipment technology develops, we are visiting significant leaps in rate, quality, and also most significantly, automation. Product packaging equipment is going to the robotics and also they are most likely to become the standard on the most effective product packaging lines throughout the world for various factors. The much better ready you are for this shift, the much better off your firm will be.

Production line automation allows firms to leverage resourcefulness and also performed without compromising workmanship or top quality. With an automatic production line, you never have to bother with workers getting sick, you can feel confident that production degrees will certainly stay high, and you can feel great knowing that completion product will be made to a continually greater criterion.

Robot packaging automation, particularly, mimics human motions to take the human running out the process without compromising the yield of the procedure. This does not eliminate the demand permanently team. Instead, it provides a possibility to eliminate the repetitive, inexperienced jobs that numerous human beings find dull as well as unfulfilling yet are crucial to conference manufacturing needs.

In other words, robotic packaging automation provides an opportunity to optimize your personnel while keeping or enhancing performance. That’s a win/win situation for you, your workers, as well as your firm.

Types Of Packing Machines

Product packaging equipment refers to the machines that are made use of wrap, seal and also box products for transport. Here are some common types of industrial packaging machines.

Air packers: Air packers utilize atmospheric pressure to blow materials into a bag with a fill spout. Air packers are typically made use of for efficient and also the quick filling of great powders like sand, concrete, charcoal powder and also laser toner.

Auger packers: Auger packers use augers to “screw-feed” products into a bag via a fill spout. Auger packers are used for fine and also nonabrasive powders, consisting of flour, powdered sugar and also dried out milk products.

Bagging Machines: Bagging machines is any of various gadgets that position things inside a bag. The bag is secured as well as ready for shipping.

Food Packing Machines: Food packing machines describes different kinds of product packaging equipment that are defined by the item that they package (specifically, food products) as opposed to the method of product packaging they do.

Form, fill and sealers (FFS): Form, fill and sealers (FFS) take a v-fold or flat material, create it right into a container or bag and after that load and also secure it.

Heat Sealers: Heat sealers are machines that use warmth to seal product packaging.

Hot Air Sealers: Hot air sealers are a type of continuous activity bag sealant that utilize hot air to heat a container for securing.

Impulse Sealers: Impulse sealers are tools that seal making use of warmth. They are regularly little as well as by hand run and also have a heating element that warms up various products to create a seal when pushed versus the warm resource.

Packaging systems: Packaging systems are 2 or more separate industrial packaging machines that have actually been incorporated together to give a natural system.

Pharmaceutical packaging equipment: Pharmaceutical packaging equipment refers to a broad series of machines developed to accomplish packaging as well as filling functions for the pharmaceutical market.

Rotary sealers: Rotary sealers are machinery for packaging pndustry that utilize a constant activity to seal bundles.

What Machinery Can Be Used for Packaging Industry?

The list of machines below is common product packaging devices made use of throughout the world. Devices can differ in size significantly yet still do the very same fundamental functions. Every one of the machines belongs to the procedure of packaging products for transport, storage space, and also sale. There are many more customized and typical product packaging makers used throughout the globe.

Accumulators

Put at the end of a packaging line to sort and collect ended up products. Collectors save the area by turning products in a collection location. There are several dimensions as well as arrangements of accumulators depending on the application as well as the product being packaged.

Air Pillow Machines

Air cushion devices insert air into pouches to develop an air pillow. The air cushions are used to support items throughout transportation. The air lowers spaces within the plan to keep items from relocating throughout transportation.

Bag Openers

Bag openers use air to open up different bags. An essential for greater rate bag loading procedures. The majority of bag openers utilize wicketed bags or bags on rolls. As the air blows the bag open, products are put for product packaging.

Bag Sealers

Bag sealers are utilized to completely confine bags made from several materials. The term “bag sealers” consists of various devices all developed to completely enclose as well as secure bags. Most bag sealers are level wire seals to make wider and also stronger seals.

Bagging Machines

Getting machines to pour items into bags after being opened. Bagging machines permit workers to have constant amounts of products placed into bags every single time.

Capping Machines

Cappers can be made use of containers, bottles, as well as jars to use lid caps after the product fills the container. Cappers for huge computerized product packaging lines can cap thousands of items per hr.

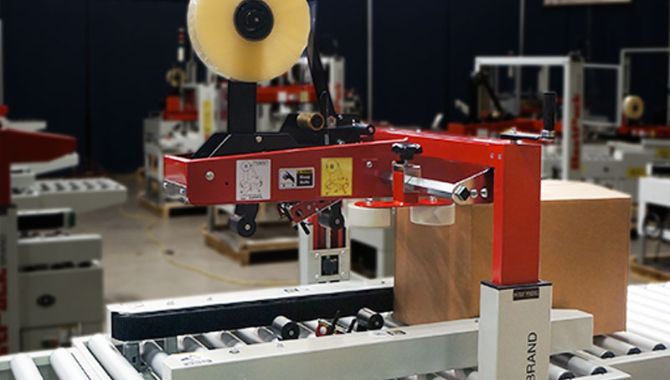

Carton Sealers

Carton sealers utilize tape to shut boxes. As the box moves through the carton sealer, tape is used. Top, as well as bottom container sealants, secure all open box sides. Container sealants with the appropriate tape can lower product damages and also rise performance.

Case Erectors

Flat boxes are developed as well as folded for products to be put right into. Put at the start of a packaging line before a container sealer for boxes to move along a conveyor and be loaded.

Checkweighers

With making use of a conveyor belt, a check weigher precisely matches the weight of a product as it goes by on a conveyor belt. Customers can pre-programmed the desired weight, as well as the conveyor, will stop if products are not within the wanted weight.

Conveyors

Conveyors transportation products from one location to an additional desired area. Conveyors can be used anytime within a product packaging line. Constant product packaging lines are fully automated with conveyors from start to finish. They are among one of the most integral parts of a totally automated product packaging line. They come in a range of sizes and kinds. Some are gravity-powered, however, the majority are electrically powered.

Filling Machines

Filling up devices are utilized with fluids and gels to control a constant quantity of fluids being placed into a container, jar, or one more container.

Flow wrappers

Food all over the world is covered utilizing flow wrappers. Products wrapped with a circulation wrapper have simple tear rigid edges. Circulation wrappers are for high-speed product packaging applications. The majority of circulation wrappers cover a minimum of 60– 80 products per min.

Labelers

Made use of to use tags to plans, products, containers, and also extra. A labeller can be portable as well as used in a warehouse for labelling items as well as boxes. Labellers can likewise be on a product packaging line to apply labels to bottles or ended up items.

Lidding Machine

A lidding machine is used to seal a meddle evident cover over products to guarantee consumers items have actually not been opened prior to usage. Secured lids can be found under the cap of lots of containers containing fluids.

Travel Luggage Wrapping Machines

Some airport terminals supply the option of using baggage covering machine. Lots of firms handling and delivering luggage use a travel luggage wrapping device to pack multiple items of luggage with each other. They aid to settle items and also minimize meddling while in transit.

Metal Detectors

Metal detectors are made use of conveyor belts to discover metal in items. Steel detectors can be utilized on automatic packaging lines together with check weighers. Metal detectors can include a vehicle ejection function to immediately remove products with metal in them.

Overwrapper

A layer of PVC film, trays and thermal pads are used together with the overwrapping machine. Many kinds of meat, vegetables, and fruits are overwrappers.

High-speed overwrappers can cover hundreds, even countless items per hour. The overwrap shields consumable products from insects, dust, and other external components.

Robots

Robots are reliable and precise. In today’s high manufacturing packaging lines, robotics is an important part of many locations throughout the line. Robotic layouts and also sizes can be substantially various depending upon each application.

Scales

A scale can be used for considering products or a collection of items within a totally automated packaging line. Scales are also a fundamental part of product packaging and shipping items via parcel or products. All outward bound products must be gauged as well as evaluated when delivering by means of the parcel.

Shrink Tunnels

Utilizing warmth and also a conveyor belt, shrink passages relocate products with a heated chamber. The warmth from the passage creates diminish cover materials to shrink and also conform to the product being wrapped.

Shrink Wrap Sealers

Shrink wrap sealers make use of warm to heal reduce cover materials together. Reduce wrap sealants seal and cut the excess film for good-looking seals. Various than bag sealants which feature wider seals for much better closure.

Strapping Machines

Strapping machines are excellent for packing numerous products together. A polypropylene strapping is wrapped around products to increase strength or connect multiple items with each other. Fully automatic strapping machines are capable of doing more than a band per secondly.

Stretch Wrap Machines

Stretch wrap devices are used to apply stretch film to pallets of items. The stretch film pulls snugly around the pallet being covered to hold products in place throughout delivery. There are various designs for stretch wrap machines based upon manufacturing levels. The most usual stretch wrap devices are turntable stretch cover makers. The turntable turns pallets as the film is being applied.

Vacuum Sealers

Vacuum sealers are used to customize the air within a bundle. Modified Air Packaging or MAP is utilized to assist expand the service life of consumable products. By lowering oxygen material within a package items can last longer and spoilage can be minimized.

Product Packaging Equipment Terms

Automatic (Fully-Automatic)— Packaging devices that can operate without the treatment of a driver. Operators generally just involve themselves with the replenishment of product packaging parts or containers.

Bags Per Minute (BPM)— The number of systems (bags, cartons, boxes etc.) a machine can supply within a one-minute duration.

Bead Seal– Two sides of material bonded with each other without overlapping to produce a seal along a narrow strip.

Casters— Wheels that are readily available for a lot of conveyors and sealants. They permit equipment to be easily portable in times of cleaning and also transition.

Closure— Used in packaging to shut a container or bundle.

Consumable/Wear Parts— Parts of product packaging tools that, because of damage, need to be replaced often.

Crimping— The mechanical deformation of a product. This is commonly made use of on steels.

Important Sealing Parameters— Three crucial sealing criteria that straight contribute to the seal high quality when making use of a warmth seal. These are temperature level, stress and dwell time.

Dwell Time— The time that a bag being sealed shut is exposed to stress and also heat.

Emboss Coder— A system that inscribes a date or whole lot code on a container or bag by pressing metal personalities upon it. Emboss coders flaw the bags or containers as opposed to use ink to them.

Footprint— The floor area that a tool inhabits.

Gross Weight— The weight of an item and also the container it inhabits.

Gross Weight Scale— An industrial range that is made use of to weigh a product in its final package prior to being delivered.

Group Package— A group of items that prepare to be refined by packaging equipment right into bundles as well as multi-packs.

Ink Coder— A device that codes bags or containers by pushing ink-coated personalities versus the material.

Load Cell— A gadget that reacts to stress and also gives a reading to define the source of the pressure.

Magazine— Part of the product packaging procedure that holds containers, carton blanks, brochures, labels, lids and stackable containers.

Mandrel— A mechanical setting up that is made use of to create a bag or container.

Net Weight— The gross weight of a packaged item minus the tare weight.

Shrink-wrapping— Process that supplies 5-sided security and also unitization by creating a bag from a tubular roll of polycarbonate, placing it freely over the load as well as applying warmth, either making use of gas or electrical, to reduce the film to the kind of the lots.

Stretch-Hooding— A process, more widespread than stretch wrapping, that offers 5-sided security and unitization by forming a bag from a tubular roll of thermoplastic, and also stretches it over the entire tons. The under pallet stretch feature provides more load stability by unitizing the lots with the pallet.

Stretch wrapping— Process that entails covering thermoplastic film securely around an item.

Supported Materials— Materials that can not be melted yet are heat-sealable.

Tare Weight— only the weight of the bag or container.

Trimmer— Used to cut off excess amounts of the product after a packaging procedure has actually been finished.

Applications of Machinery for Packaging Industry

Usually, products want packaging for security purposes, yet they can also be for easy transport and also handling. This product packaging can protect from impact, extreme temperature levels, and also dampness especially for food products that can be polluted.

Packaging is a useful source for storage and also enhanced efficiency when managing products for retail purposes. Food product packaging equipment is developed to manage compounds that would be uncontrollable for employees such as sugar and flour. Having this type of machinery, businesses have the ability to have rapid and reliable methods of packaging for numerous markets such as food packaging, electronic devices, agriculture, production, as well as drugs. Here are some usual applications for product packaging equipment consist of:

- chemical and petrochemical.

- cosmetics as well as perfumery.

- electronic devices as well as semiconductors.

- food and foodservice.

- household item.

- armed force.

- video and software.

What is the expected cost of investing in packaging equipment?

In order to comprehend the expense of your packaging equipment, you should first understand your particular needs, the kind of machine you call for, and also the added alternatives you desire for your particular applications. It is very important to additionally take into consideration including a contracted preventative maintenance plan or employing a committed service professional to prepare your downtime on your own terms.

With all this in mind, the fact is that the cost of packaging equipment is very sensitive. This is to state, the expenditure related to your packaging line might differ greatly from your competitors. As each packaging line is unique with its own variety of machinery, products, energy demands, drivers, geographical location as well as etc., the price connected with one line to the next is seldom identical.

In the area below, we will certainly take a look at the different dynamics of a product packaging line and the associated expenses pertaining to purchasing machinery, products, as well as the other elements needed to effectively run your devices. Here are some steps to help us to understand the cost of packing equipment.

Step1. 7 Questions to Ask

If you want to know the cost of packing equipment, there are 7 questions you need to ask before you make a decision.

1. When you think about cost, what is the first thing that enters your mind?

- Cost of purchase?

- Price of ownership?

- Cash?

2. Is the acquisition price more important to you than the performance of the machine?

- If so, will it still be in 3-5 years?

3. Just how usually will you be utilizing the maker?

- Twice a week?

- 24/7?

4. How capable is your internal maintenance specialist?

5. Can you deal with sophisticated devices or do you need fundamental controls?

6. Are your maker operators going to be designated generally to this line, or will they walk around?

7. Do you like to be on the leading edge of innovation, or would you rather leave the most recent product packaging modern technologies to the adventurers in your industry?

Step 2. Determine Your Film Usage

Next, you’ll require to end up being much more aware of the mathematics involved in your packaging materials. Let’s take diminish film as an example. Rate per roll is an essential vibrant to think about, nonetheless, your price per bundle is a lot more essential. Comprehending what each bundle prices, exactly how to calculate it, and just how you can conserve money will place you in a better placement to budget plan suitably as well as make the most of price performance.

The mathematics starts with a decision of your real film use and then introduces your actual cost per bundle:

Film length split by film cut-off, minus the rewrap percentage, equals your film usage. Let’s state, as an example, that your film length is the common 4,375 feet per roll for 60-gauge centre-folded film. Transformed to inches, that is 52,500. Assume the film cut-off is 11 inches. If you split this, it concerns roughly 4,772 packages per roll. Subtract the rewrap per cent of, state, 3%, and also you obtain roughly 4,629 packages per roll of film.

Step 3. Establish Your Price Per Package

This is much easier mathematics, as it’s simply just how much each roll costs you to purchase, divided by your film usage. So let’s say you are paying $128 per roll of film. Divide this number by 4,629 bundles and after that increase by 1,000. You develop a true plan price of $27.65 per thousand packages.

MATHEMATICS EQUATION:

$ 128 per roll

4,629.57 bundles per roll

128 ÷ 4,629.57 =.2765.

.2765 × 1,000 = $27.65 per thousand plans.

Utilize these computations to create a strong expectation of your shrink wrap plan cost. Then consider the following suggestions for minimizing that number.

Tips To Manage machinery Costs for packaging industry

When you want to purchase a packaging machine, it is very important to manage the cost. Here are some tips to manage the costs of your packaging equipment.

Discuss Your Equipment Costs.

When conference with your sales associate, ask about special deals, rebates, and additional chances to reduce the price of your acquisition. Product packaging equipment is a huge financial investment and there might be various ways in which you can lower the cost of your purchase.

Keep It Simple

When buying machinery for packaging industry, you are likely going to get a deal from various sales reps. Unfortunately, many sales specialists will attempt to offer you a Cadillac when all you truly require is a Toyota. When obtaining quotes from your chosen suppliers make certain to inquire about obtaining a base machine with no bells as well as whistles and also just adding the choices you in fact require to efficiently package your items.

It is likewise important to ask for quotes from several different producers. Sometimes you can get an essentially similar offering from one business that is hundreds of bucks less than their competitors despite any significant difference in between theirs and the various other suppliers’ equipment.

Truth be told, occasionally you are merely paying extra for a brand name. When it pertains to packaging tools, getting a product because it is one of the most well-known brand names in the sector does not always equate to the best packaged products. You might in fact get better equipment from a lesser-known brand name that packages your item perfectly.

Consider Your Options

There are numerous dynamics for buying packaging equipment and also their connected procedure that is not a cookie-cutter remedy for each business. There are some aspects of buying and also running product packaging equipment in which there are at least two alternatives. One option might be right for your organization as well as incorrect for the following. These include:.

Buying brand-new, used, or reconditioned devices. Each of these alternatives features very various rate factors and also its own major toughness and also weak points. As for which is right for you, this will largely depend on your budget plan, items, as well as the products you pick to run on your equipment.

Working with versus getting technical service. For some companies with large manufacturing as well as a product packaging line that runs 24/7, a dedicated internal service technician may be an excellent financial investment, but it is not the best fit or the ideal choice for all businesses.

Dealing with a representative versus purchasing direct. Each of these options has numerous advantages and disadvantages. Which makes one of the most sense for your business? That is totally dependent upon your special requirements. Getting quotes from both a representative and also an OEM will allow you to contrast the pros and cons of each and also make an enlightened decision on which vendor is a better fit for your business.

Preventative Maintenance

When purchasing packaging equipment, the preventive maintenance plan is an additional price consideration, but it will save you countless dollars. When parts wear out, they can create breakdowns that might cause extensive downtime as well as result in extremely costly repairs. If you are on top of routine maintenance, you will certainly decrease the threat of more damages.

Damages may occur to other parts of your equipment when a damaged part stops working, let alone the threat of injury to your labour force. A normal preventative upkeep plan will significantly decrease downtime, maintain your machinery going for peak performance and also ensure fast repair work and also service telephone calls.

Try Different Material Formulations

A different material formula might lower your expense on the machinery that runs it. IE: stretch wrappers as well as shrink machinery. What many firms typically neglect is that there could be greater than one kind of material that helps a particular item.

Obtain A Machinery Analysis

Generate an associate from a number of different vendors as well as have them run an evaluation of your existing packaging line. This will certainly offer both of you a big collection of important info concerning your particular product packaging procedures such as your existing tools, products, and procedures. This info will certainly enable you and your associate to discover means to improve upon your current procedures before updating to brand-new equipment.

Things to Consider for Purchasing Machinery for Packaging Pndustry

It is essential to recognize some specifics about your item to be packaged prior to purchasing a piece of product packaging equipment. As an example, the products that you will certainly be running on your line are a crucial consideration when intending to get new equipment.

If you are most likely to be purchasing shrink film machinery, you will intend to look at all the different types of diminishing film in addition to the various determines of films that are readily available. Picking the wrong kind, scale, and size of the film can cost your company thousands of bucks with time.

A few of the product packaging factors to consider you’ll require to be knowledgeable about consist of:

- What sort of product you are packaging.

- The product’s weight, form, and also dimensions.

- Your purposes for colour and labelling.

- Whether the film can be printed to fulfil your demands.

- Exactly how the item will be packaged into the adaptable film (manually or by means of equipment, and also what type of machine).

- The item’s trip from development to delivery to the shelf and also past.

- Whether it will certainly be handled often and/or subject to misuse.

- The types of climates/environments it will experience.

- Whether it requires specific film additives to maintain it fresh (e.g., oxygen or moisture obstacle).

- Demands for anti-tampering and safety of the finished good.

Trick Consideration: Working With A Distributor VS. Buying Direct.

When you are attempting to determine where you must purchase your packaging equipment from, selecting to go direct to the maker is a common option. Besides, who understands their machinery better than individuals who are developing stated makers? You can be sure that the producer knows their equipment throughout. Therefore, they ought to have the ability to answer your most discerning inquiries.

That being stated, the producer will certainly be prejudiced when answering concerns like “which is the most effective brand name of machinery for packaging industry to buy” or “which producer supplies the very best solution”?

Currently, as there are various ups as well as downs when purchasing from an OEM, so it is with a representative. From the price of items to client service as well as quality in repair work, suppliers have their strengths as well as weaknesses.

Relying on different factors including your geographical area, budget restrictions, and also other characteristics such as your assembly line’s present framework, a distributor might or might not be the very best option for your firm.

There is an absolute myriad of considerations when picking packaging tools and also materials are just one of the most crucial products to take into consideration. Along with product packaging equipment and materials, the setting and environment also are very important characteristics to consider. Working with a distributor will enable you to evaluate a variety of alternatives and also they will have the ability to aid you to obtain the best details, advice, and products for your requirements.

Key Consideration: Extreme Temperatures

Globe in human hand against the blue sky. Environmental protection concept. Components of this image furnished by NASA.

Severe warmth or cool has to be balanced out by heating or cooling systems where severe temperatures are the standard. Whether this indicates you stay in a place where it is constantly one extreme or the following, or if you live in a location that can see both extremes throughout the year, making certain that you have the appropriate heating as well as cooling down systems in place is something to take seriously.

Key Consideration: Environmental Concerns

As the pneumatic modern technology is not only extremely out-of-date, yet it is also poor for the setting as it makes use of an excessive quantity of electrical power. So when it involves the setting and also industrial packaging machines, there is no doubt that people don’t like to use pneumatic machinery.

Some devices have actually totally eliminated pneumatically-driven elements all together which results in massive expense financial savings as pressed air is one of the costliest energies in a plant.

Advantages of using non-pneumatic equipment include:

- High-level efficiency with light scale films, as well as, PE films.

- No Product/No Bag. So, you’re not throwing away the product.

- 10-15% film cost savings generally.

- Power regrowth with every cycle.

Because air cylinders wear, eliminating pneumatics will minimize purchasing replacements and also the disposal of them also. Some non-pneumatic equipment additionally supply what is called “servo technology” which does not require you to add added flooring area and numerous conveyors to obtain the appropriate spacing in between items.

Various other makers also provide what is known as “lean technology” which eliminates film breaks. This indicates you don’t have to re-wrap loads and toss added material away. Generally, makers with lean technology usage less worldly with a unique metered film delivery system.

In addition to negating or getting rid of pneumatically-driven technology from your packaging line, making certain to run eco-friendly materials is also an important consideration.

While much of the steels that make up industrial packaging machines can be recycled, certain products can not or merely are not recycled.

When choosing packaging materials, it is necessary to consider the use of multifunctional product packaging materials, such as reduced films and stretch films, to replace high-carbon footprint items such as glass, metal, and cardboard.

While also being considerably more affordable than these various other materials, diminish film and also stretch film remain in reality completely recyclable. And with a substantially lower carbon impact than the aforementioned choices, versatile product packaging products are in reality a far better option for the environment.

Key Consideration: Moving Your Production Line

Family members relocating house taking boxes right into a truck – isolated over a white history.

Relying on the sorts of equipment you are running as well as just how said tools is set out, it would be smart to produce a plan for moving the appropriate tools at the right time. Relying on the size, electrical demands, physical place on your line, and weight of your equipment, some planning in advance is a vital dynamic of this procedure.

Connecting to your machinery for packaging industry as well as materials rep to assist you to develop a strategy based upon the dynamics above will enable you to take a preemptive strike against unnecessary or repetitive activities during transportation and also setup of your machinery in its new location.

Depending upon the circulation of your packaging line, certain machinery ought to be installed initially to guarantee an efficient and timely instalment. As for which device you need to relocate first, well, this is instance delicate for each company and must be determined by you and your technological solution get in touch with.

Secret Consideration: Should You Buy Or Lease Your Packaging Machinery?

Getting new machinery is a large investment for lots of companies and usually, purchasers are unclear or uneducated about the procedure. One extremely crucial factor to consider to think of instantly is, should you purchase or rent the machinery you are intending to obtain?

The truth is neither choice is one size fits all. Each has its own benefits and drawbacks and also a various set of applications as well as line characteristics that would suggest one superior to the various other. Inevitably your unique needs, format, and budget plan will identify which choice is best for your service.

There are however some considerations to ponder that will certainly assist you to choose which option is best for your packaging line and also the special applications in which it is involved. So with that in mind, allow’s examine a couple of crucial elements of choosing to get or lease your product packaging equipment.

Focus on Your Overall Needs as well as Time structure.

Capital investments must be made strategically as well as with the future in mind. Several of the important things you’ll want to consider when vetting renting brand-new industrial packaging machines over funding consist of how much you plan to make use of the machinery, the number of equipment you will certainly be seeking to acquire, prospective capitalists in your organization, and lastly, your balance sheets.

Suggestion exchange concept. Concepts arrangement Investing in business advancement and also monetary commerce backing of creativity. Open up the lightbulb icon with gear mechanisms. Funding possible ingenious growth.

What is Your Budget?

Does it make even more sense to purchase your equipment outright or do you require to start out with leasing based upon your spending plan? In evaluating/making an acquiring choice on equipment, people sometimes puzzle the ability to validate the acquisition with the capacity to pay for the purchase. The capability to justify the acquisition (ROI) is based upon a service choice that the payback satisfies your needs for investment.

What Type of Technology Do do You Need?

If you wish to have the best machinery on the market, you may need to do a little added excavating to discover more recent technologies that supply the most effective lease choices for your service. That isn’t to say that they won’t be readily available, it just may take some added research and also research study. Consequently, having a supplier that has experience in device leasing within the product packaging sector is essential.

Complete Guide to Choose Suitable Packing Machiner, manufacturers and Packaging Material

When it comes to selecting a manufacturer for your packaging materials and equipment, it is important to do your homework and also ask on your own a few inquiries. You must examine a minimum of 3 various providers and also discover several crucial dynamics from each of them.

Location

It is a great concept to select a packaging machinery manufacturers who is reasonably near your geographical place or can conveniently take a trip to you. This will have an effect on your business when there is a demand for repairs or emergency situation service for your devices. Choose a vendor that remains in an additional country as well as you may find yourself dead in the water for days on end. Picking a vendor with technicians who are regional is constantly a wise suggestion. When it pertains to your materials, you do not need to be as bothered with the physical area as the majority of supplies can be shipped promptly.

Professionals

It is essential to select a packaging machine provider with skilled and certified service technicians who are expertly trained to work on your product packaging devices. Without the proper certifications, you are gambling with your equipment. You might end up paying huge when taking the chance of solution with non-certified technologies.

Client service

It might be appealing to source the most inexpensive product packaging products in an effort to conserve cash, however, if you buy from a firm with inadequate customer care, you may wind up shedding the anticipated financial savings anyway. Poor service usually suggests lost bucks. Have a look at evaluations of each packaging machinery manufacturers as well as if possible, reach out to existing clients and ask about their supplier’s customer support as well as if they would certainly recommend buying from them.

Price

There is an old stating in the packaging industry is “diminish film is shrink film”. While there are some brand names with flashy marketing and also sales tricks with a premium rate, chances are, there are several much less expensive choices that are of equal top quality. If you are looking for comparisons, there are generally low-cost films that have reduced clearness and also higher-cost films that will certainly radiate more as well as have better quality. Picking a cost-effective film may cost you in shelf visibility.

Snake oil and also elevator pitches can blur the line between reality and also an illusion. At the end of the day, you will certainly wish to purchase from an honest vendor who brings several offerings at various rate points as well as offers exceptional customer care.

Components

Depending on how commonly your equipment is running, your downtime because of fix demands or emergency service will certainly differ. As time is money, it is essential to ask your maker distributor about lead times, parts availability, and preventative maintenance programs.

Ask each potential vendor what their typical reaction times for emergency situation phone calls are. In many cases, it needs to not be greater than 24-48 hours.

Which Packaging Materials Should You Use?

Various types of machinery need various types of products and utilize different quantities of products based on the make and model of devices. As an example, while you can save money upfront by purchasing a hands-on L-Bar Sealer, your cost of products will likely be higher as an extra expensive automated sealer will generally utilize much less material than the hands-on machine since the equipment will usually be optimized to do so.

That being claimed, the amount of product that you will be generating needs to additionally be considered. An automated sealant will not be the best machine for a small company that is just running a couple of thousand products or much less each week.

This results from the reality that each version is designed to work with certain maximum as well as minimum abilities as well as products. Every set of equipment is various. Your packaging line’s special demands need to be considered when selecting the proper maker for your application. This can cause higher manufacturing expenses if your choice of equipment can not run thinner gauge reduce film. Making use of thinner gauges of shrink film can result in considerable cost savings.

Top 10 Global Packaging Machinery Manufacturers in the World

Here are the top 10 packaging machinery manufacturers in the world for your reference.

ADELPHI PACKAGING MACHINERY

The Adelphi Group is one of the leading packaging machinery manufacturers. The company provides a variety of packaging and processing machinery and tools, including cosmetics and personal treatments, food and beverages, pharmaceuticals and health care, laboratories and research, agrochemicals, household chemistry, e-liquids, and more. The Adelphi Group achieved organic growth through a few strategic purchases and today merged four separate but complementary divisions; Adelphi Manufacturing, Adelphi Cold Flow, Adelphi Masterfile and Adelphi Healthcare Packaging.

KRONES AG

Krones is taken part in planning, creating, and also manufacturing equipment as well as full lines for the areas of processing, filling, as well as product packaging remedies. The packaging machinery manufacturer runs with 3 company sections, particularly Machines and Lines for Product Filling as well as Decoration, Machines as well as Lines for Beverage Production/Process Technology, and also Machines and Lines for the Compact Class.

FUJI MACHINERY

FUJI MACHINERY has been a dedicated packaging machinery manufacturer regularly applying to develop product packaging innovation, as well as to the manufacturing as well as sales of packing machinery.

FUJI’s first product packaging machine was a caramel wrapping maker that took place sale in 1948. Afterwards, we continued to develop product packaging machinery for food as well as other numerous products, and today we have grown to be referred to as “Technological and also High-quality FUJI”, a leading firm in the product packaging machinery industry.

BERHALTER AG

BERHALTER is the top firm in die-cutting. The name BERHALTER is associated with the production of ingenious and also customized die-cutting systems. BERHALTER is the world’s only supplier of flat die-cutting machines and has its own tool manufacturing workshop.

With its high-performance die-cutting equipment and also a professional for die-cutting devices, it offers custom-made services– 100% Made in Switzerland. Consequently, the series of applications for BERHALTER die-cutting systems recognizes no bounds– systems that permit both intricate covers as well as tag geometries in addition to a wide variety of various products to be efficiently refined and also die-cut to perfection.

SCAGLIA INDEVA SPA:

A cutting edge material taking care of the system that allows lots of up to 320 kg to be raised as well as moved entirely effortlessly. Scaglia SpA was the very first company to be granted the UNI EN ISO 9001:1994 Quality System Certification (today ISO 9001.2008) for the design, production and sale of material handling systems. In 2004, Scaglia Spa split and also the former Material Handling Division came to be Scaglia INDEVA SpA.

Scaglia Indeva is a top-quality packaging machinery manufacturers in the layout as well as production of state of the art industrial manipulators, product handling systems as well as lean manufacturing options. The manipulators by INDEVA are the perfect remedy for managing reels, situations, drums, bottles, etc. in a fast, ergonomic and risk-free way. They are used, as an example, to pack reels into shrink-wrapping devices, or to discharge cardboard situations from the palletizer. They are present globally with a network of branches, distributors as well as agents.

WEST ROCK

WEST Rock is one of the packaging machinery manufacturers that supply a competitive advantage, a companion that can provide regular top quality and also superior solution, a partner that gas development to promote real, lasting development.

We have a lengthy background in entrepreneurship, leadership as well as innovation. That history includes game-changing growths in papermaking, packaging layout and retail remedies, in addition to purposefully building and reinforcing our business’s capacities gradually.

With procedures all over the world and also expertise in every buying group, we concentrate on collaborating with brand names to help them win across the board by offering an unequalled portfolio of paper and also product packaging products. We’re developing unsurpassable product packaging services together.

EUROMAC COSTRUZIONI MECCANICHE S.R.L

Euromac is the most significant and most skilled packaging machinery manufacturers in Italy as well as one of the leading distributors worldwide. High-tech machinery such as slitting machines and rewinders for the production of plastic films, laminates, paper, aluminium foil and other food and non-food flexible packaging materials.

BOSCH PACKAGING MACHINERY:

Bosch Packaging Technology department is among the leading packaging machinery manufacturers as well as packaging innovation. In over 30 areas in more than 15 nations worldwide, a highly qualified workforce develops and also creates complete services for the drugs, food, and also confectionery industries. These solutions are matched by an extensive after-sales solution profile. An international service and sales network gives clients local points of contact.

MITSUBISHI ELECTRIC CORPORATION

Mitsubishi Electric Corporation (TOKYO: 6503) is an identified world packaging machinery manufacturer in the manufacturing advertising and sales of electric and digital equipment used in data processing and also interactions, room development and satellite communications, consumer electronics, industrial technology, power, transport and also structure equipment. Welcoming the spirit of its corporate statement, Changes right, and its environmental declaration, Eco Changes, Mitsubishi Electric undertakings to be an international, leading environment-friendly company, enhancing culture with modern technology. The company videotaped combined team sales of US$ 38.8 billion *.

Conclusion

Purchasing packaging machinery is a major investment. The different characteristics of choosing equipment consist of; security, spending plan, physical layout, electrical supply, products, and also a whole host of considerations that can make your head spin.

When moving forward with the buying procedure it is important to start by assessing the proper KPIs with an emphasis on safety and security first. Next, you will intend to make certain to complete the packaging equipment pre-investment checklist. After filling out the info in this useful tool as well as obtaining your results back, you will wish to go on to obtain quotes from at the very least two or three suppliers.

Obtaining an evaluation of your product packaging division and collecting data on your existing machinery, manual labour, products, physical impact, electrical needs, production levels, types of products and also the other important characteristics of running a secure and effective product packaging line is essential.

When you have had the ability to totally evaluate every aspect of your product packaging line, asking for quotes from each of the suppliers you are offering a possibility to price estimate will certainly provide you with satisfaction that you are going obtain the most effective offer and obtain the best of what each supplier has to supply.

Along with inquiring and pricing on the packaging machinery, you are aiming to acquire, be sure to additionally obtain information concerning the price of service, installation, any training offered, supply, as well as repair services. Preferably, you ought to think about getting a quote for a lasting preventative upkeep plan as this kind of program will guarantee that your equipment is always performing at peak performance and that downtime will be limited when it does happen.

Once you have picked a vendor to buy from, meeting your agent as well as assessing the machinery offerings that they have will permit you to open up a conversation concerning prices. Here you can inquire about special deals, refunds, additional alternatives, leasing versus getting, as well as various other related characteristics that will help you to obtain the best cost as well as ideal plan implemented for your specific budgetary restrictions and also product packaging line needs.

Lastly, it would certainly do you well to schedule quarterly, bi-annual or yearly conferences for review with your chosen vendor’s sales representative as well as among their maintenance technicians.

This will permit you to assess data from one conference to the following and also determine places where your equipment and products could be surpassed to lower your cost of production, boost speed to market, create a greater performance as well as create a superior performance on your packaging lines KPIs.

If you still have any other questions about purchasing a packaging machine, you can feel free to contact Jochamp to help you.