Pouch Packing Machine Manufacturer in China

JOCHAMP is a well-known pouch packaging machine manufacturer in China. Our dependable customers all over the world benefit from our high-quality and cost-effective pouch packing machines. It’s our responsibility to satisfy our customers’ requirements.

- Low noise operation

- Intelligent fault diagnosis function

- Safety limiter, door stop device to ensure safety

- Hot and cold double sealing system, 100% airtightness

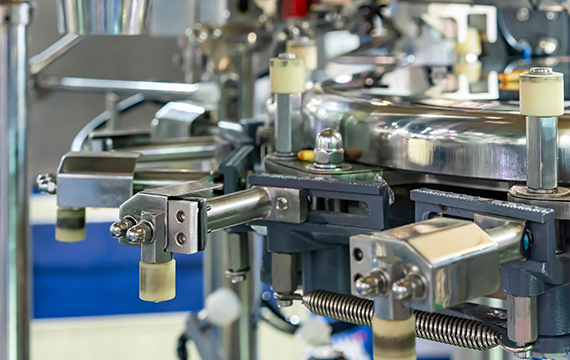

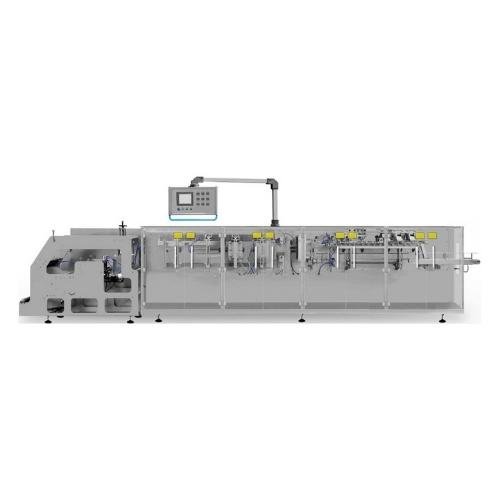

JOCHAMP Pouch Packing Machine

A pouch packing machine is an exclusive equipment used in packing products into pouches. It has utilized a variety of methods to pack different products in pouches. However, it becomes popular in established businesses and industries due to its outstanding competence to pack particular items into diverse pouch styles. JOCHAMP pouch packing machine is accessible in different machine types that work on a similar basic function of packaging. That has a perfect packaging quality that makes it suitable for most solid, liquid, and combined products found in the market.

All pouch packing machines from JOCHAMP are economically provided. It is highly productive and easy to operate. Whether you are looking for any kind of flexible pouch packing machine for your industry, then a turnkey solution for your needs is JOCHAMP. Here, we can customize your desired machine according to your product requirements and budget.

Pouch Packing Machine Advantages

Integrating a pouch packing machine will improve the productivity of the operations and warehousing while also reducing the risk of quality problems.

The pouch packing machine is primarily configurable to the needs of the production line. It can also be utilized with other types of packaging materials. Get yours now at JOCHAMP.

Rather than acquiring and inventorying a variety of bags. Pouch packing machines allow you to purchase film rolls and use them to create bags of various sizes.

A pouch packing machine will eliminate errors. Automation will increase packing quality and reduce the risk of items being damaged. Choose JOCHAMP for the best solutions.

Pouch Packing Machine Highlighting Performance

High-Speed Packaging. The increased level of machine automation leads our pouch packing machine to have an explicit improvement in terms of sustainability and packaging speed. The machine can pack plenty of different products much faster with much greater precision.

Diversified Packing Forms/Styles. The pouch packing machine has great strides in functionality and mechanism. Regardless of the measurement, volume, and control quantity of the product, this machine can perform at a high-accuracy level, specifically in terms of the size and shape of the package.

Promotes a High Degree of Safety and Protection. The pouch packaging machine is an environmentally safe and user-friendly type of machine. It has exceeded protection in terms of the health condition of all workers and operators since this machine is dust-proof and not capable of producing some irritating substances.

Pouch Packing Machine Various Option

JOCHAMP offer numerous type of pouch packing machine that immensely assist with start-up and established business. Some of them are the following:

Pre-made Pouch Packing Machine. It is a moderate operation machine that usually uses pre-made bags. That is perfect for moderate packaging, and average production facilities.

Rotary Pre-made Vacuum Packing Machine. Most used machine in packing fresh meat products, fish, and more. A machine that utilized a vacuum process in making the bags or pouches free from the air, making the products last longer. Although these machines pack different products, they have similar work in bag loading, date printing, sealing and packaging.

Pouch Packing Machine Associated Qualities

Automation. A pouch packing machine is a high technology-driven system that ensures an increased production rate. It also reduces the possibility of packaging errors and mistakes during operation.

Portable Design. The pouch packing machine has a compact structure and flexible qualities, like being easy to maneuver from one place to another. It has an innovative composition that makes it ideal for today’s modern packaging.

Machine Maintenance. The type of packing machine is easy to install and requires less maintenance. It is durable and has the potential to work continuously for an extended period.

Why Choose JOCHAMP for Your Pouch Packing Machine

JOCHAMP has accumulated a decade of years of experience in the packaging machine industry. We offer different types of machines used for product packaging including the pouch packing machine. All the machine we have is not just only technologically sound but also comes with 100% hygienic packaging technology.

The features and properties of our pouch packing machine enormously benefited the packaging line. It ensures to conduct flawless packaging, obtaining the industrial standard. The durable sealing and packaging properties of our pouch packing machine guarantee that all products are 100% protected from external environment and weather and spillage and damage.

JOCHAMP engineers are coming up with a comprehensive solution for pouch packing machines which leads the packaging business and market to build up a continuous development. Want to know further details? If you are interested in our pouch packing machine, please contact us anytime and expect prompt responses!

The pouch packing machine is fundamentally composed of standard components that are completely associated with the entire production:

- Encoding Machine

- PLC Control System

- Vacuum Generator

- Frequency Converter

- Dust Removal Device

- Temperature Controller

- Solenoid Valve

- Servo Motors

- Digital Control

- Output System

The pouch packing machine relatively comes with straightforward application use, yet guarantees providing higher efficiency, quality, and dynamic performance.

- Uses alternate frequency speed directive devices

- Adjustable operation speed within the specified production range

- Zero waste materials

- Automatically detects flaw

- Gives consistent packaging rate

- Energy and time-consuming

- Provides a perfect packaging pattern and durable sealing quality

- Complies with both industrial and hygienic standards

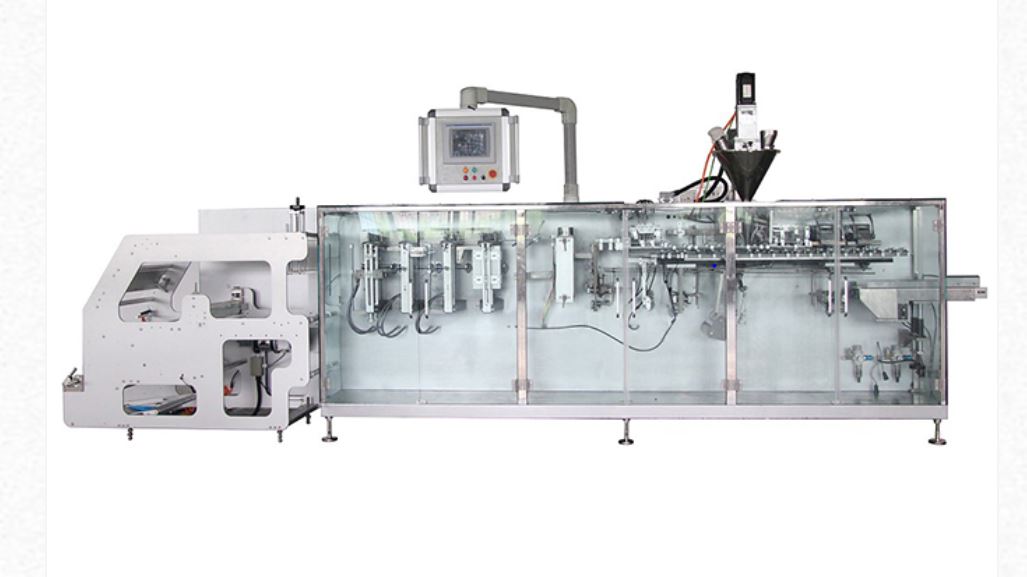

JOCHAMP Pouch Packing Machine For Industries Packing Solutions

JOCHAMP pouch packing machines are ideal packaging machines for the industries of food, pharmaceuticals, cosmetics, fine chemicals, or agrochemicals. Coffee powder, tea bags, drinks, yogurt, syrup, detergent, shampoo, and other liquid and solid products can be packed with flexible filling mechanisms. The machine’s output is notable for its high seal strength, dependability, and aesthetic appeal.

The pouch packing machine series specializes in filling and sealing stand-up pouches and flat sachets. With the right packaging machine type, it may automatically pack the product in a standard 3-sided or 4-sided flat sachet, a premade standard doypack, a prefabricated zipper function sachet, a premade top spout sachet, or a premade corner spout sachet.

A multi-head weigher, auger scale, volumetric cup filler, liquid pump, and other filling equipment are available to work with the pouch packing machine. Most organizations prefer arrangements with various types of lifters, working platforms, and discharge conveyors.

The pouch packing machine includes a rotary fill and seal packaging machine, conveyor, and linear weigher, which is flexible to add or lessen according to customers’ different requirements. It is widely applied to pack granules, solids, liquids, and powder products. Suitable pouch types: flat pouches, standup pouches or doypacks, zipper bags, quad bottom pouches, etc.

Optional

Pouch Packing Machine: The Ultimate Guide

There are many designs of pouch packing machines in the market. This guide will help you choose highly efficient and reliable pouch packing machine.

Let’s dive right in.

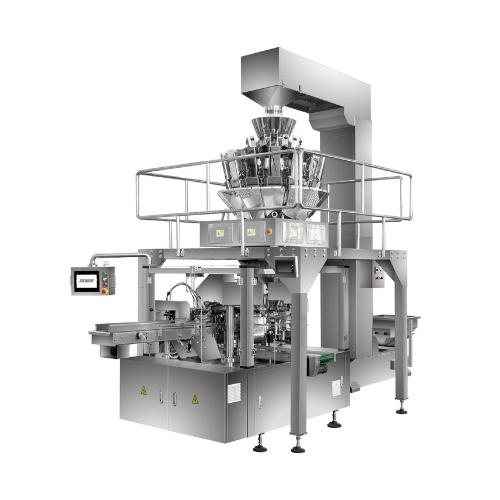

Rotary Packing Machine

A rotary packing machine has rotating type columns with different stations based on the type of models of the machine.

Benefits:

- High-speed operations

- Quality maintenance of products

- Easy to use the machine

- Less labor intensity

- High-efficiency level

- Quick fill and consistency unit weight of the products

rotary packing machine

Limitations

- Require skilled personnel to run the machine effectively

- Expensive to purchase

- Risk of confusion when branding is needed.

Working Principle:

It has two rotating kinds of columns.

The first column loads the bag, opens and does the filling of the bag

The second column is for creating a vacuum and also seals the bags.

After the operation, the already sealed bag is discharged by the output type conveyor belt from the machine.

Doypack Packaging Machine

It is suitable for big or large-sized granules and crooked lumps, for instance, nuts.

Benefits:

- Ease of use

- Cheap and fast

- Flexible

- Reliable

Disadvantages

- Low speed, unlike high-speed machine

- Require skilled person

- Risk of confusion

Working Principle:

It takes up an empty material, opens it, and then fills in the product, after which it seals.

Spouts are fed at the sealing point with the help of the orientations.

It works with single-width packets.

Doypack packaging machine

Pick Fill Seal Machine

Pick and fill machines fill different kinds of solids, liquids, and powders of various products.

Benefits:

- Automated machine

- Flexibility to different products

- High Efficiency

- Quality of products is maintained

- Easy to use

- Less costly

- Simple machines

Limitations:

- A skilled person required to operate

- High risk of confusion

- Expensive to purchase

pick fill seal machine

Working Principle:

Since it is designed with a rotary layout, it picks fills and seals the pouches as they are moved from one station to the next.

It can perform up to 200 bags per minute.

Movement is in a circular layout.

Bags are manually loaded into the machine by the operator to the conveyor.

After the sensor detects the bag, it is picked to the grippers.

Printing can be done if need be.

A bag is opened when enclosed at the lower end.

An opened bag is filled with the product in place based on the operation

Settling of some products is allowed before sealing is done.

The product is cooled to products requiring a cooling system, after which the pouch is discharged from the machine.

Premade Pouch Packing Machine

A premade pouch packaging machine contains a premade bag that can measure and pack materials based on the specifications.

Benefits:

- Ease to use

- Faster operations

- Quality productions

- It is flexible

- It is reliable

- Automatic operations

Limitations:

- Needs skilled personnel to operate

- Susceptible to mistakes by the operator due to different operations

- More activities hence increased labor cost

premade pouch packing machine

Working Principle:

It comprises parts that are made and designed pre-set since they work on the already made bags with a single opening of the bag ready for filling and sealing.

Its parts move in a pre-set kind of sequence.

The machine picks an already made bag in the sequence of operation, passed to be filled at the filling point.

After the filling is done, the bag is moved to a sealing station for sealing to be done.

High Speed Pouch Packing Machine

It is a machine that allows sachets to use while packing products.

Benefits:

- Highest reliability level and efficiency

- Easy to use

- Robust moving system

- Three to four filling stations

- Offer the biggest capacity of filming reel.

Disadvantages:

- Require skilled personnel.

- It can be risky while brand due to speed.

Working Principle:

Due to high speed, the machines contain thermo servos which aid in maintaining the speed at a high level.

It is set in a rotary manner to allow the effectiveness of the machine.

It covers several products within a minute due to its high-speed nature.

high speed pouch packing machine

Stand Up Pouch Packing Machine

It is used largely in doy bag filling and sealing processes.

Benefits:

- Good for snacks, even rice, and food for pets.

- Applicable for different styles of packing

Disadvantages:

- Less speed, unlike high-speed packing machines

- Require a skilled person to operate the machine

Working Principle:

It is designed so that the packing bag being filled is upright; hence, the name stands for pouch packing.

A packing bag is picked at the filling point, moved to the filling point as the bag is filled, and moved to the sealing point.

stand up pouch packing machine

Paper Pouch Packing Machine

It is a machine type that uses films as they are turned into a paper bag shape.

Benefits:

- Very fast

- Quite economical in use

- Small in size hence saves money

- Low budget costs

Disadvantages:

- Few bags making per minute compared to high speed.

- Papers can burn up in cases of high temperatures

- Skilled personnel is required to run the machine.

Working Principle:

The film is used to turn it appear into a paper bag shape.

After the paper bag is shaped, it is filled and sealed at specific points.

A spindle holds the filming roll.

The film moves on to the dancer avoiding tension.

After the unwinding process, the film goes through the printing and then to the mark registration points.

The bag moves to the tube forming point, which overlaps as the film gains the bag shape.

Bags are then filled and sealed with products.

paper pouch packing machine

Zipper Pouch Packing Machine

It is a machine that cuts the zip film to make a zipper kind of a bag.

Benefits:

- Ease to use

- Fast speed

- Auto stopping system when a machine has no product

- Has a photo eye sensor

Disadvantages:

Cutting parts risky to the operator

Need for skilled personnel to operate the machine

Any slight mistake causes the machine to mislead the entire process as wrong cutting is done.

Working Principle:

Packing material is placed on the silicon moving conveyor that allows the cutting of the packing bag into desired shape and size.

Since the machine blows zipping lock film bag in a spiral way, various clients’ specifications determine the kind of locks to use.

zipper pouch packing machine

The packing bag is then filled and sealed through the processes.

Spout Pouch Filling Machine

It is a machine that fills and caps pouches that are flexible with a spout using a filling piston as closing is done using a screwing type cap.

Benefits:

- Flexible

- Ease to use

- Quality products

Disadvantages:

- Require skilled person

- Require a bit of manual operations

Working Principle:

A pouch is placed at the collar.

A volumetric filling machine will detect the product volume.

The filling is done by pressing the button.

Nitrogen can be forced into the packing bag to increase shelf life.

Sealing is done as the cap is tightened and as the use of torque is adjusted.

spout pouch filling machine

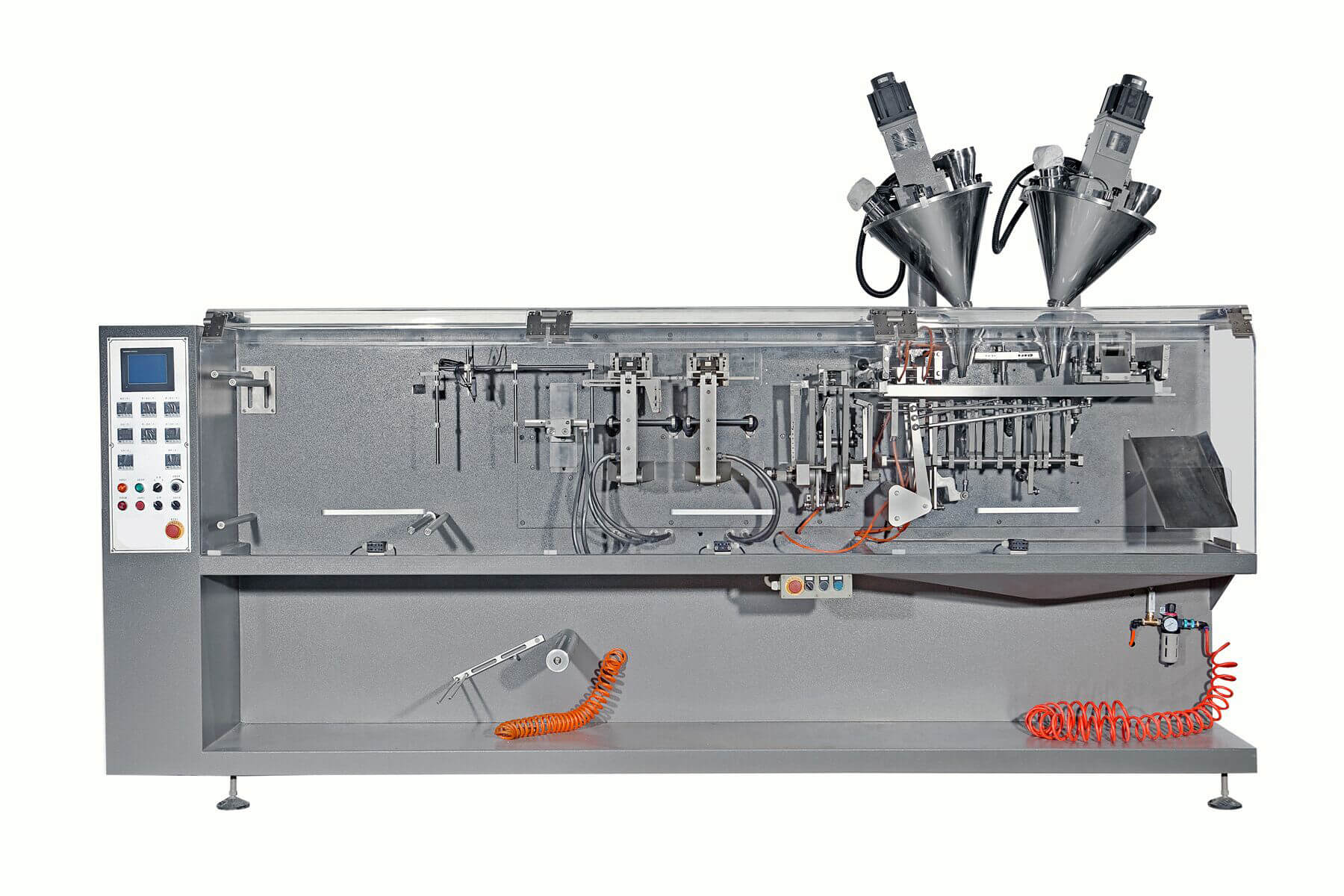

Horizontal Pouch Packing Machine

It is the machine that can fill the products in a pack and seal them.

Benefits:

- Can contain wet products at the same time dry products

- Flexible

- Cheap and fast

Disadvantages:

- Limited capacity productions

- Operator required

Working Principle:

A roll of film is run on a plow hence gusset bottom.

The film is flat-folded, hence moving to different seal points.

Filling of the product is done on the top.

Sealing is done, and the bag is expelled from the machine.

horizontal pouch packing machine

Vertical Pouch Packing Machine

A machine consisting of one sheet of film rolled round to the core, commonly called a rolling stock, works on a web film of continued packing material bags.

Benefits:

- High speed

- Flexible as it works in different industrial applications.

- Economical in the packing process

- Conservative in the floor plant spacing.

- Easy to use

- Easy to control

- Less labor required

Disadvantages:

- A skilled person is required to run the machine

- Only suitable for vertically erected bags

Working Principle:

Film Movement

A spindle holds the roll film on the machine.

While the machine operations are in place, moving belts removes the film from the roll.

In other cases, the sealing kind of jaws grips films downward through the machine without belts.

Tensioning The Film

In the unwinding process, the film is let off the roll, passing over an arm dancer having several rollers.

Movement of the film causes an upward and downward arm movement to keep the film in tension manner, hence no wandering of the film sides.

Printing

Based on the type of the printer, the process is done on the film as coding can be printed alongside dates and graphic designs.

Also other preferred printouts as the client’s specifications can be printed.

Positioning Of The Film And Its Tracking

It is done after printing as the film is taken through a photo-eye type registration process.

It positions film and presents it to the cutting point.

After positioning, a sensor confirms the right positioning of the film.

A wrong film alignment will move the entire sheet to the right position via the actuator.

Forming A Bag

The film is folded and presented to the edges for bag forming.

The presence of a lapping tube helps in sealing the outer edges of the bag.

Filling And Sealing The Bag

Bags are received in a vertical way to allow filling and sealing.

Discharge

Discharging the packed bag is done based on the machine’s endpoint.

vertical pouch packing machine

A manual machine is generally slower compared to a fully automatic packing machine.

Automatic pouch packing machines offer a uniform and consistent unit product in each packing bag, unlike manual machines that are manually fed repeatedly.

With automatic pouch packing machines, the quality of the product is maintained by the client and offers easy shipment than the manual packing machine.

The automatic machine reduces material waste, especially in wrapping cases, compared to the manual packing machine, as wastes cannot easily be managed.

Automatic packing requires less labor as a single person can easily operate the machine compared to manual packing machines that require manual feeding to discharge.

Fully automatic packing has high efficiency and takes all the activities into performance compared to the semi-automatic packing machine.

A semi-automatic packing machine can rectify a mistake during the operation, while a fully automatic machine cannot redo the task.

The cost of purchasing a fully automatic packing machine is higher than that of a semi-automatic one.

A semi-automatic machine requires a combination of labor to fully perform its duty.

On the other hand, a fully automatic machine that requires less manning during its full operation.

Water pouch packing machines

A pouch packing machine can also pack drinking water to maintain quality and offer low water contamination.

Milk pouch packing machine

Milk is packed and sealed using a pouch packing machine that does not require intense actions during operations.

Oil pouch packing machine

Oil is packed and sealed to be transported to the market.

Masala pouch packing machine

The pouch packing machine can pack Masala in powder and solid forms. This is quite efficient and reliable as different products are packed using the same machine.

Tea pouch packing machine

It is easy to use the tea packed by the pouch packing machine in small bags in offices or other places requiring quick service deliveries.

Pouch juice packing machine

A pouch packing machine is used to pack juices in beverage companies. Different juices are packed and sealed as they are graded based on the juice type or content of the product.

Pouch shampoo packing machine

The liquid shampoo is well packed and sealed within the pouch to maintain its shelf life.

Pharmaceutical industry

It is used in pharmaceutical industries to pack and seal drugs and other medicinal products for marketing and transportation to various required places.

Cosmetics industry

Beauty products are packed and sealed in an enclosed vessel that preserves the product through its vase life.

· Auger Filling Mechanism

Auger fillers mainly fill powder products.

Powders can be free-flowing like salt particles and non freely flowing powders like milk powders and flour powders.

Free moving powders cannot easily be dispensed and hence cannot be pressed further.

Auger fillers use an auger screw part that dispenses the products.

Its screw moves materials ahead in a rotating manner.

Settling The Required Parameters

An operator does it through the controlling system.

Empty Vessels Feeding

The operator manually feeds empty containers in the machine for semi-automated auger fillers and manual auger fillers.

Conveyors are used to arranging the empty vessels for filling.

Filling The Containers

For accuracy feeding to the drill, a hopper is used.

Augers having weighing scales are always exempted as the machine uses volumetric powder filling machines.

The Auger screw is rotated by its drive while feeding powder to the hopper’s tubing.

An agitated blade moves opposite the screw to break inconsistent materials, hence a free-moving powder product.

· New Weight Filling Mechanism

Filler machines use weighing scales o measure the exact product before filling it into the machine.

Semi-automated and automated methods are both used.

The semi-automated method puts containers below the fillers as a button pressed.

Additionally, the button stops immediately after a given-sized weight is achieved.

Process rewinds over again.

Automated ones are fast and offer reduced operator works.

With automated fillers, the process starts to the end as the vessels move below the fillers.

The slow movement offers an accurate process, but fast movement offers quick results.

Three different set points controlled are the target weight and the dribble weight as the final one is preacted.

Fast movement of the filling cycle moves to the dribble after which, when it arrives at the preact, the valve closes as the vessel reaches the targeted weight.

Different nozzle types are used based on speed selection and the type of container to use in the filling process.

· Volumetric Filling Mechanism

There are three types of volumetric filling mechanisms.

Pump Filling Mechanism

Pumps are used to transfer products from tanks to containers.

It is suitable for highly viscous products to avoid clogging pump parts.

Pumps with a peristaltic nature have flexible tubes and rollers that help separate the products from the pump parts in motion.

It is suitable for dangerous fluids and also pharmaceutical fluids.

Gravity Kind Of Feeding System

Gravity is used to force through the products to the vessels.

It is suitable for foaming kinds of products.

It is best suited for a thin kind of viscosity.

Work in different temperature ranges.

It offers a quiet working environment

Piston Type Mechanism

Valves are opened by the piston’s fillers flowing directly from a hopper straight to the cylinder.

A full piston will force the product into the container via the nozzles.

It suits different products of different viscosity and densities.

· Pump Dosing Mechanism

Since it is powered using an electric motor, the pump, after retaining a weighed amount of liquid in its chamber, is injected into the tank or even a pipe having the fluid dosed.

It manages the flow rate of the fluid being dosed.

· Capping Sealing

Inline Screwing Capping System Machines/ Spindling Method

As the sides’ belts tightly hold the container to avoid rotations, on the conveyor, three to four discs are used to spin a container cap tightly.

It is a simple method to use.

Retorque Kind Of Machines

It is almost like the inline capping system.

It only works on retightening, though they require no use of a feeding and sorting system like the inline system.

Commonly used where aluminum foil sealing is done, causing loose caps.

Snapping Mechanisms

It is similar to inline though it presses the cap using an overhead design.

Chuck Method

It uses chuck as it grips a cap while spinning it on the bottle.

It has a clutch for the torque method to work, as the machines use one or more heads to fasten production.

· Heat Sealing

Its medium of sealing the materials is by use of heat.

Due to its ability to produce a high impulse currency on the device surface, bags to be sealed are pressed and sealed as the bag is melted due to the strong heat provision.

Heating sealing bags to certain temperatures melt materials that stick together similarly to a bag containing zip liners.

· Ultrasonic Sealing

It uses the vibrations from the acoustic to provide heat inside a film in a molecular manner.

Vibrations force molecules to move to create a way in which a seal is achieved by rounding the container in place.

The welded materials in the process are required for sealing.

It is best used in food companies.

Dimensions Of Packing Bags Or Containers

For flat-shaped bags, width and length are sufficient, but depth along length and width are required for footed bags.

Packing Weights Or Volume

Weights of the container or packing bag loads are a key indicator of the type of machine to purchase.

Legal Requirements

Some countries might be strict about the importation of certain machines.

Nature Of The Packing Product

For solids, particle sizes a machine can pack are key indicators while purchasing the machine.

For liquids, the viscosity level is an important factor to consider while buying a machine for packing.

Temperature The Machine Uses To fill

Different materials are subjected to different temperature rates during packing processes, either hot, cold, or room temperatures.

Type Of The Filling Head

Different machines use different filling heads for insistence, using a premade machine and a doypack machine.

It determines the type of product to pack and the operation in place.

Control System

A complete automatic control system reduces labor intensity compared to manual machines.

For all your pouch packing machines, contact us now.