Flow Wrapping Machine Supplier in China

Jochamp is a reliable flow wrapping machine manufacturer in China. This machine uses various types of film and foils in packaging different products. They are good inclusion to your packaging business and projects.

- Corrosion-resistant, IP65 grade machine

- Easy to maintain, simple installation

- Made of durable stainless steel construction

- With budget-friendly Asian price

Custom Flow Wrapping Machine - JOCHAMP

Flow wrapping is becoming an important technique for packaging various products with any type of foils and film. These machines are used to package vegetables, fruits, bakery, candy, and confectionery items, as well as industrial products like hardware.

We customize our flow wrapping machine based on our customers’ precise needs and specifications. If you are interested in any of our machines, please contact us directly.

Types of Flow Wrapping Machines

Flow Wrapping Machine Features

All of the machines we offer are made of tough, strong stainless steel that is ideal for the harshest work conditions.

Our high-speed, accurate flow wrapper provides precise packaging solutions that surpass various custom specifications.

Jochamp machines are known for their high efficiency and stability. All are thoroughly made to meet your expectations.

Flow wrapping machines can be used in a variety of industries, including food and beverages in granule, liquid, pickle, and powder form.

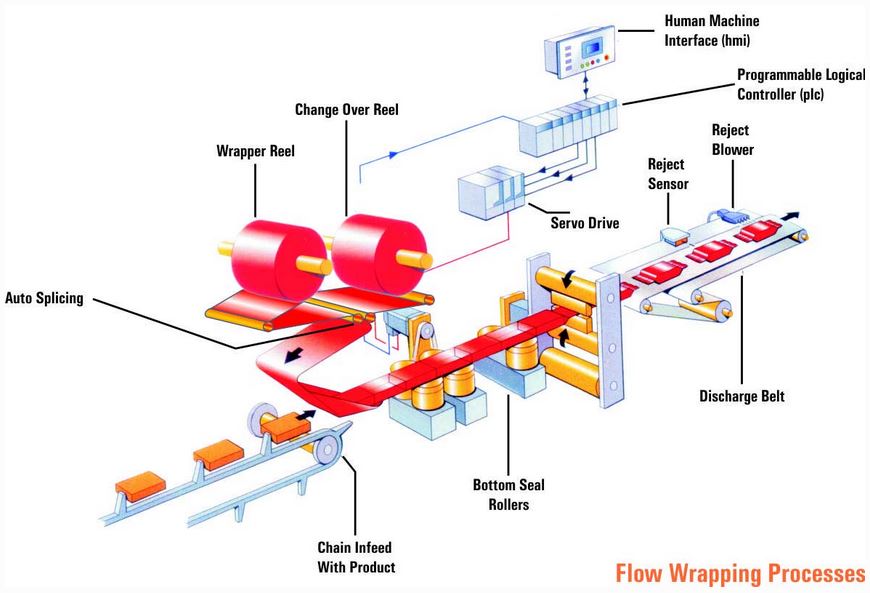

Flow Wrapping Machine Workflow

Flow wrapping machine assist manufacturers in increasing the speed and efficiency of their packaging processes. Jochamp can provide you with a user-friendly flow wrapping system regardless of your needs.

To begin, an in-feed conveyor places and transports your items into a containing box. This containing box applies wrapping film around the product on machines equipped with rotary sealers. The film is then sealed and cut to shape the bag.

When this procedure is finished, the sealable product is ready to be boxed and shipped.

Why Flow Wrap Machine?

Choose our flow wrap machine for your packaging industry. It offers numerous advantages for your application, such as:

- Provides added layer of protection from environmental contamination.

- Available in varying compositions and thicknesses for your packaging solution.

- Flow wrapped goods offer exceptional opportunities for improved branding and increased retail sales.

- Offers high-speed, automatic alternative packaging solution. Speeds up to 70-packs each min.

Custom Flow Wrapping Machine With Us!

Extensive Knowledge – Over 1000 projects completed in over 15 years of producing and trading.

High Speed and Dependable Quality – ISO9001&CE certified, sophisticated technology allows for rapid packaging.

Competitive Pricing – Offering a complete supply chain and a high throughput at the best cost.

Efficient Service – From concept to completion, a professional team will assist you. Simple to use.

JOCHAMP | Leading Flow Wrapping Machine Supplier in China

JOCHAMP is the market leader in China for manufacturing and exporting flow wrapping machines. Our R&D Department and sales advisers have at least 15 years of experience and have worked on over 1000 major packaging projects, including upgrading, designing, and installing the entire line.

Our packaging lines are commonly used in medicine, food, cosmetics, and other industries. We also offer great and customized solutions for upgrading and adding value.

Jochamp is your one-stop solution for custom-made flow wrapping machines. All of these machines have passed CE, ISO9001, and cGMP certifications. We’re looking forward to your inquiry. Send us a direct message!

You can include our flow wrapping machines, regardless of your industry. They are efficient, reliable packaging solutions ideal for:

- Beverage

- Food industry

- Chemical

- Medical field

- Commodity

- Textiles

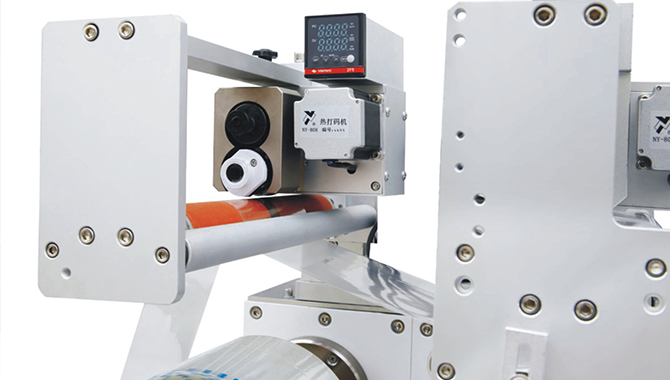

Jochamp provides these custom-made packaging machines with complete features such as,

- Easy operation, compact construction, and stable operation.

- Double frequency converter controller; eliminating the need for adjustment and speeding up the process and film.

- Employs imported electric appliances, a touch manmachine interface, and a simple parameter configuration.

- Self-checking function; trouble can be easily read.

- High sensor photoelectric color chart tracking; allowing for a more accurate cutting position.

Products You Can Pack with Flow Wrapping Machine

Compared to other brands’ machines, Jochamp flow wrapping machine is commonly 50% quicker. This machine uses fewer resources and energy for packing pet and animal food into a pouch. It is an energy-efficient, reliable, and functional machine.

Using a flow wrapping machine for your packaging business will help you save time, money, and space. This machine also provides excellent versatility. Numerous household products can be flow wrapped no matter the items’ characteristics and shapes.

For industrial and automotive products, our flow wrapping machines are ideal. The finished packaging is a powerful advertising tool, resulting in improved brand loyalty. It provides detailed information and significantly contributes to the actual sale of an item.

The plastic used in the wrapping process of medical products is LDPE (low-density polyethylene). It is recyclable plastic, therefore it can be reused. Whatever type of packaging machine you required, Jochamp can meet your requirements. Our packaging machine such as flow wrapping machine has high durability, and keeps the products for around 3-5 times longer.

Related Products

Flow Wrapping Machine: The Ultimate Guide

In this guide, you will find all information about flow wrapping machines. Whether you want to learn about features, parts, working principle, application, material section or any other aspects of flow wrapping machine – you will find all information right here.

This is a machine that is used to wrap a variety of products at very high speeds and usually in huge quantities.

They use a plastic film or a foil to seal products thus protecting them from contamination, damage and to retain their quality and freshness for consumables.

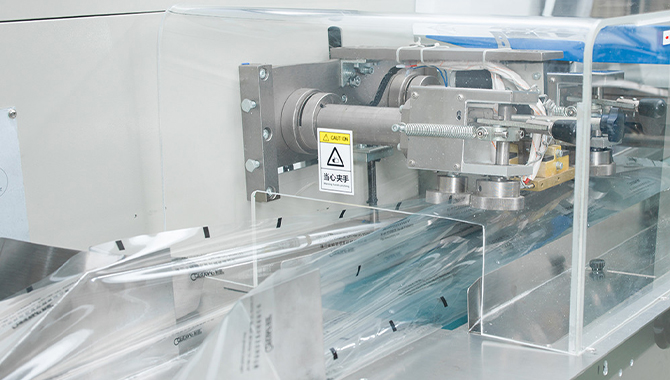

flow wrap machine

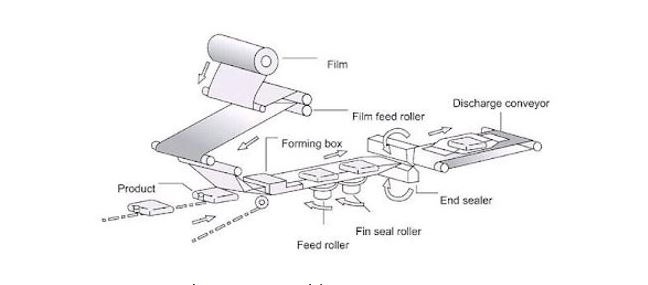

The working principle of a Flow Wrapping Machine is in such a way that single products are lined up by a conveyor to a forming box.

The products are then surrounded by a continuous film tune created by the forming box.

The items are then separated using a combination of rotary heat sealers and cutters into single product wrappers.

The products that have already been sealed and packed are then ejected from the machine into packing boxes for transportation.

flow wrapping process

Flow Wrapping Machines are widely used in very many industries dealing in a variety of products. They include:

Household Products

An array of products used at home such as paper napkins and sponges are normally wrapped using this machine.

Others using the Flow Wrapping Machine for packaging are disposable cutlery and wet or dry wipes.

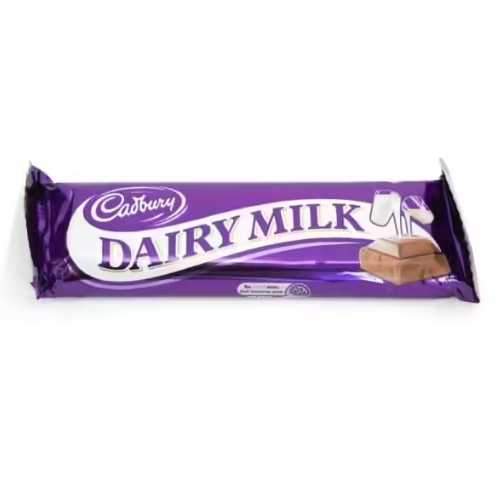

Baking Industry

A variety of confectionaries such as muesli bars and lollipops are wrapped using this machine. Chocolates and many other sweets use the same machine to wrap them before packaging.

Stationeries

Very many magazines are packaged using this machine to prevent readers from reading them before purchase.

Reams of papers, some books, cards and pens can also be wrapped with this machine.

The Flow Wrapping Machine usually wraps the product using various types of materials depending on product specifications. They include:

Polyethylene Terephthalate (PET)

This type of plastic wrapping is normally used on food products and is mainly made of thermoplastic polymer.

Polyethylene (PE)

This is a synthetic resin that is versatile and light originating from ethylene polymerization

Biaxially Oriented Polypropylene Films (BOPP)

In the event that high strength and clarity are required in wrapping a product, then the Biaxially Oriented Polypropylene Film is the most suitable.

It also ensures that the product remains fresh all through.

The Flow Wrapping Machine has the following main components:

Infeed Conveyor

It is responsible for moving the products using pushers so that they can be wrapped.

The chains on it have lugs or pushers where the products are manually or automatically placed depending on the machine design.

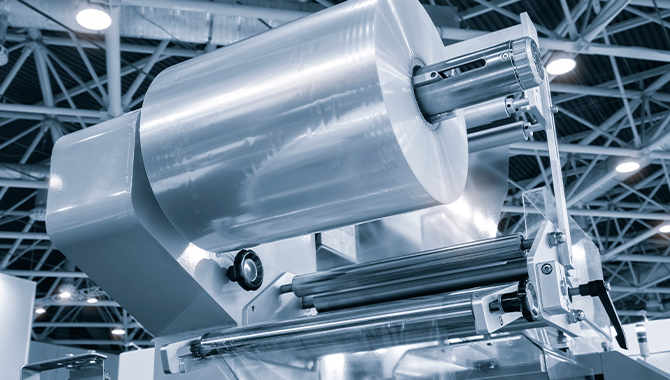

Back Stand

It has reel holders (either one or two depending on the machine) with other incorporated technology like powered film reels.

It also contains an automatic film tracking technology to ensure smooth wrapping.

Feed Roll

It is located on the back stand and is responsible for supporting the film movement using driven rollers.

Converter Splice Detector

It us used to spot markers that are available on the reel and ejects those that are faulty once they pass through the discharge belt.

Splicer

It is used to connect two different film reels by joining an empty film reel at one end with a with a new film reel.

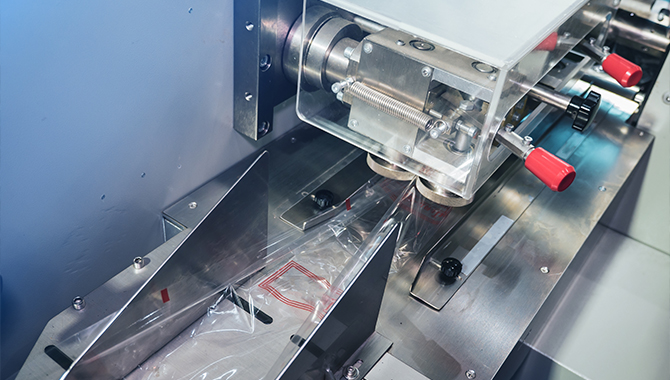

Film Cutter

Works in conjunction with the splicer and separates the different packages after wrapping by cutting them. It greatly reduces the rate of rejection of the packages.

Film Reel Holders

These holders are self-centering and assist in adjusting the film center and aligning it with that of the machine thus eliminating manual adjustments.

Pushers

They are responsible for conveying the products into the former in a forward motion for them to be wrapped.

Fin Wheels

Used to seal the products two mating edges by folding over the fin strip over inside the package in readiness for the end seal by the jaws.

Former

This is where the packages pass through when a layer of sealing material is used to wrap them and their base mated.

End Seal Crimpers

Composed of two rotating shafts with each having between 1 to 4 crimpers having straight or serrated knives.

These are the ones that are used to cut the packages.

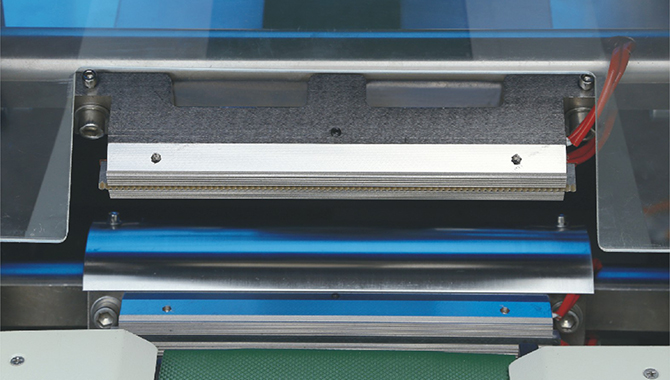

Rotary Heat Sealer

Responsible for creating airtight packages that are protected from any form of damage by using heat for the final sealing.

flow wrap machine components

i. Any form of maintenance procedure should be carried out by a professional or an operator professionally trained on maintenance procedures.

ii. Regular scheduled maintenance should be arranged periodically and parts prone to wear and tear replaced.

iii. In the event that the machine remains dormant for a long time, it should be thoroughly cleaned and anti-rust oil applied.

It should then be covered to protect it from dust, water and extreme temperatures.

iv. Grease and oil the regular moving and transmission parts with oil levels being monitored regularly.

v. The machines maintenance history should be well documented to have an accurate service and breakdown trend.

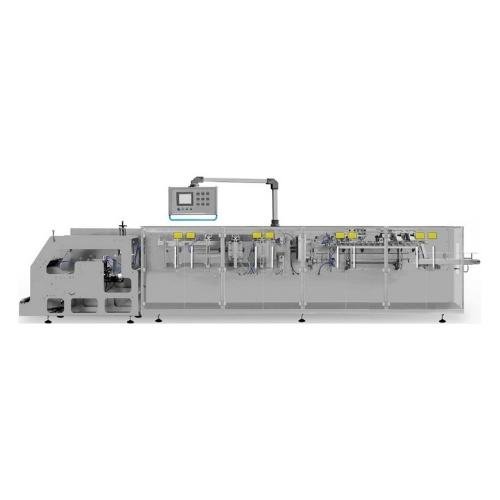

There are various types of a Flow Wrapping Machines available in the market. They include:

Box Motion Flow Wrapping Machine

Mostly used for wrapping heavy and very large products with very long sealing time to produce high quality thick seals.

Due to the airtight seal they provide, they are best suited in wrapping Modified Atmosphere Products (MAP).

box motion flow wrap machine

Back Seal Flow Wrapping Machine

The film is this machine is positioned on the bottom side and fed from that reel therefore eliminating the use of trays for products that are loose.

back seal flow wrapping machine

Long Dwell Flow Wrapping Machine

This machine is normally uses one brushless motor and sealing is made efficient by a long dwell head on the machine.

The machine achieves very high flexibility levels with quality wrappings on the products.

Rotary Motion Flow Wrapping Machine

It is mostly used in wrapping non-barrier materials and those that are eco-friendly and can be recycled.

Side Sealing Flow Wrapping Machine

This type of machine usually wraps products that have been sliced in a very unique way.

side sealing flow wrapping machine

Rotary Jaw Flow Wrapping Machine

This machine operates at very high speeds by using the end seal jaws that rotate to produce the speed required.

rotary jaw flow wrapping machine

The operation of a Flow Wrapping Machine involves the products moving along a conveyor belt in a horizontal direction.

The products have both their ends sealed by the machine and then wrapped.

The products in a Shrink Wrapping Machine are normally enveloped in a clear film then passed through heat.

This is to ensure that the film wraps tightly around the product making it very compact.

Shrink Wrapped Products are protected from dirt and humidity with the process increasing storage with minimal costs.

Flow Wrapped products have minimal movement after packaging, are airtight with decreased material waste.

shrink wrapping machine

Shrink Wrapping Machine is recommended for products such as bottled drinks, food stuff and pharmaceuticals.

Flow Wrapping Machine is suitable for products such as stationeries, chocolate bars or even biscuits.

Certain precautions should be taken when operating a Flow Wrapping Machine to ensure safety and efficiency. They include:

i. Ensure that the fixed-grip wheel is properly fastened and the inner film roller supported fully by the outer and inner rollers.

ii. The film center point and the film carrier center point must always be in the same position.

This allows the film trace to be successfully recorded by the eye trace sensor.

iii. The product width should determine the adjustment of the machines bag front width. The gap should be small to allow easy passage of the product.

iv. The Flow Wrapping Machine should be installed at an angle and not horizontally.

For the film to be smoothly fed from the film roll, the recommended angle is 15-20° in regard to the upper left position.

The Flow Wrapping has many benefits to the manufacturer and the products it wraps that include:

Improved Hygiene

The Flow Wrapping Machines greatly minimizes the human contact with the product being handled through automation.

Contamination is thus avoided in addition to nitrogen used in packaging that keeps the food fresh for longer.

Increased Production

Due to the high operating speed of the Flow Wrapping Machine, very many products can be packaged in a very short time.

This increases the companies output which in turn leads to increased sales.

Product Preservation

Flow Wrapping Machines ensure that the product is sufficiently sealed hence keeping it fresh for longer.

It also protects it from oxygen, contamination and Ultraviolet rays therefore making it safe for use.

Ease Of Transportation

Since the Flow Wrapping Machine ensures the product is wrapped in a fixed position, transporting them becomes easier.

The product also experiences very minimal disturbance during transportation due to the compact wrapping.

There are certain factors to be considered before settling on the most appropriate Flow Wrapping Machine. They include:

Cost

Budgeting has to be done before purchasing and the cost of acquiring the machine should fall within the budget.

This however should not compromise the quality and efficiency of the machine that one requires.

Size

The size of the Flow Wrapping Machine should be sizeable enough to fit into the final intended premise with sufficient space left.

It should be big enough to serve the purpose for which it was acquired for.

Purpose

The qualities of a Flow Wrapping Machine assist in evaluating the right machine for the function required.

This will help in utilizing the machines abilities and fulfilling to the maximum the machines intended purpose efficiently.

Material

The materials used to manufacture the Flow Wrapping Machine selected should be rigid and very durable.

This is to ensure that it can withstand harsh conditions such as corrosion, extreme temperatures and weather conditions.

The Flow Wrapping Machine contains certain unique features that include:

i. it has an electric panel that is durable and controls the power that runs the machine.

ii. It has a Programmable Logic Control (PLC) that is responsible for regulating the sealing unit temperatures.

iii. The speed of operation and the length of the bags are regulated using double frequency inverter controls.

iv. For the safety of the operator, the jaw guards are equipped with an interlock.

v. The size of the packages can easily be adjusted through a bag former having a unique design.

Products can be fed into the Flow Wrapping Machine in three different ways:

Manual Feeding

The products are placed manually by hand between an infeed chain’s pushers with the operation speed determined by the operators feed rate.

The operators eye-hand coordination greatly impacts the machines efficiency and is not limited by the machine.

Semi-Automatic Feeding

In this form of feeding, products are manually fetched from a central production line and placed into an automatic feeding system.

It is from the feeding system that the products are transported automatically to pass between the infeed chain pushers.

Fully Automatic Feeding

This type of feeding has no form of manual interference since a belt conveys the products from the main production line.

It is then automatically fed to the flow wrappers infeed system which is also automatic.

Three types of film sealing techniques can be used in the Flow Wrapping Machine depending on the product characteristics and cost of material.

Barriers such as oxygen and UV rays together with the integrity of the seal also determine the film seal to be used.

Cold Sealing

This type of film is made up of glue placed as a thin layer and a base material also called the carrier. For sealing of the product to be achieved, the two layers of glue are pressed together without a welding process taking place.

The protection offered to the product is not quality since the seal is not hermetic.

Furthermore, the product must be stored in a temperature-controlled room since heat compromises the glue negatively.

Heat Sealing

Heat seals are the best option available when the product requires a seal with high integrity and is achieved using sealing jaws.

This means that the seal is hermetic and the product is safe from oxygen and UV rays and can be stored at any temperatures.

The sealing jaws exert pressure on the heat seal film for a given time span and then released and cut to separate the product.

The products are normally air tight and the seal bond is usually very tight thus suitable even for important documents.

Ultrasonic Sealing

This is a longitudinal unit of sealing which works together with flying cross-sealing part to seal the products.

The sealing technique is remarkably gentle and is recommended for films that can be recycled.

The Flow Wrapping Machine has very few disadvantages that include:

i. The initial cost of acquiring a Flow Wrapping Machine is normally high but the benefits in the long run are very encouraging.

ii. Some of the machines require professionals to operate them thus cost of training increases a company’s expenditure.

iii. automatic Flow Wrapping Machines are complex in nature and some breakdowns may take time to repair.

The Flow Wrapping Machine may experience problems now and again with some common ones being:

i. Sometimes the film may be fed incorrectly mostly when it has not been well threaded. This can be solved by regularly inspecting the film threading before feeding it.

ii. Inconsistencies in placing the product in the package may be caused by the film moving faster than the product.

iii. This can be rectified by increasing the infeed pitch value or reducing the value of the package length in the parameters.

iv. The product getting jammed in the forming area may be caused by slow product movement compared to the short infeed pitch film.

This is solved by adjusting both the package length and the infeed pitch.

The Semi-Automatic Flow Wrapping machine operates on both manual and automatic mode at the same time.

The operator manually feeds the machine with the materials needed for packaging and the parameters set for the automatic mode to proceed.

The Automatic Flow Wrapping Machines operates autonomously upon starting subject to certain preset parameters.

The only manual intervention is when the operator presses the touch screen when adjusting parameters or diagnosing for malfunctions.

After the manufacturing of the Flow Wrapping Machine is completed, its operational efficiency has to be ascertained.

Some of the quality control measures taken to this effect are:

Factory Acceptance Test

This test is carried out immediately after manufacturing in the premises of the manufacturer.

This is to confirm that the Flow Wrapping Machine working well with all controls and parts functioning perfectly.

Site Acceptance Test

After the Flow Wrapping Machine is delivered to the customer, a specialized team of technical professionals performs this test.

It is done at the customer’s premise and they leave the machine in perfect working condition.

Other Related Machines:

For all your flow wrapping machines, contact us now.