Side Seal

Is the traditional side seal suitable for me? This kind of seal is formed by forming a film tube around the product, sealing the film tube on its side, and removing the excess trim to the film accumulation winding machine. The advantage of the traditional side seal is that the film cut-off of products of similar size can be adjusted without changing the film. This means that cutting more or less film becomes a function of a small machine adjustment. If you have a product whose width is greater than its height, the traditional side seal is most likely the correct seal for you.

Top Seal

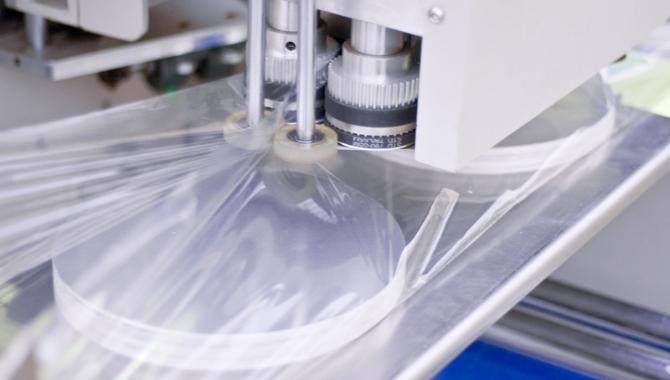

What is the difference between the traditional top seal and the traditional side seal? Basically? Nothing. Every advantage of using traditional side seals can also be found in the top seal. The main difference is that the sealing device is installed on the top of the product instead of on the side of the product. This will create a seal on the top of the product and remove any seal lines on the sides. If you have a larger product height than the width, or if you would like the sealing line on the top of the product instead of the side, the top seal is a great choice for you.

Bottom Overlap Seal

The bottom overlap seal is also called a lap seal, it is created by forming a film around a fixed molded structure that forms a film wrap around the product. The film overlaps under the product and is then sealed with static electricity or some form of energy transfer (such as heat).

Compared with traditional side seals, this type of seal has several advantages. The bottom lap seal uses less film than the traditional side seal because there is no need to cut and remove excess parts during the sealing process. No waste, overlapping sealing machines generally have fewer parts and fewer adjustments required than traditional side sealing machines as well. The bottom lap seal is a great dedicated product if the top or side seal is not the preferred aesthetic.

Zero Edge Seal

What is your opinion on saving film costs? How to eliminate the need to throw away excess film? With the recent breakthroughs in sealing technology, we have entered a new era of shrink wrapping. The zero-edge seal combines the advantages of the bottom lap seal and the traditional seal, completely eliminating the waste of the shrink wrapping machine, while still allowing easy conversion and adjustment. It is perfect for special products and can be used in top and side seal (no interior) versions. Compared with traditional sealing technology, this seal can bring maximum uptime and reliability.

Conclusion

If you produce many SKUs, need a lot of flexibility, and have a lot of short-term runs, a side sealer may be right for you. If you have been running a specific product continuously, a lap sealer can save you a lot of money

No matter what you choose when buying equipment, it is best to have a knowledgeable equipment expert by your side. Talk to our packaging professionals to find the most ideal equipment for your needs.