Nitrile Gloves Packaging Machine

Jochamp provides a custom nitrile glove packaging line according to your actual situation

- The only manufacturer that provides overall packaging line solutions for nitrile gloves

- Suitable for Nitrile gloves, latex gloves, examination gloves, surgical gloves, rubber gloves, and disposable gloves.

- 2-year warranty support

- Complete automation packaging solution for connecting latex gloves manufacturing process machine

- All contact surfaces will be food-grade materials, able to provide the cleanest environment

- Improve the consistency of product appearance

- Not only is the working time of 7×23 hours, but a box of 1000 nitrile gloves, using the nitrile glove packaging line can also reach 4-6 boxes per minute.

- A complete nitrile glove production line can replace at least 10 manual labor.

How the Nitrile Gloves Packing Line Works (3)

Multiple Transit Transmission Agencies

We have added two functions in the entire transfer conveyor device, the scrap kick function and a carton turning mechanism.

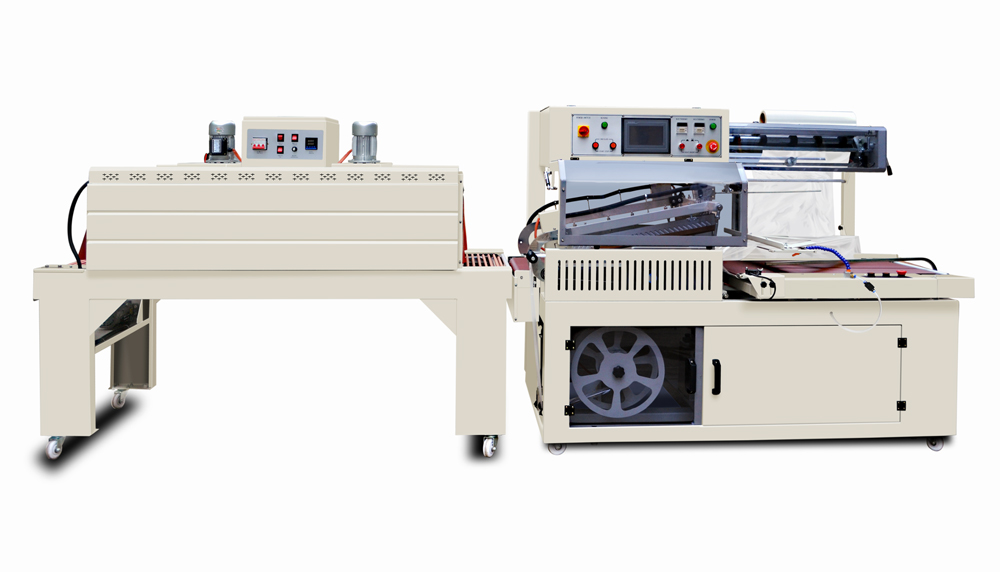

Automatic Shrink Wrap Machine

Our automatic shrink wrap machine can make 100 nitrile gloves enter the next packaging process more regularly

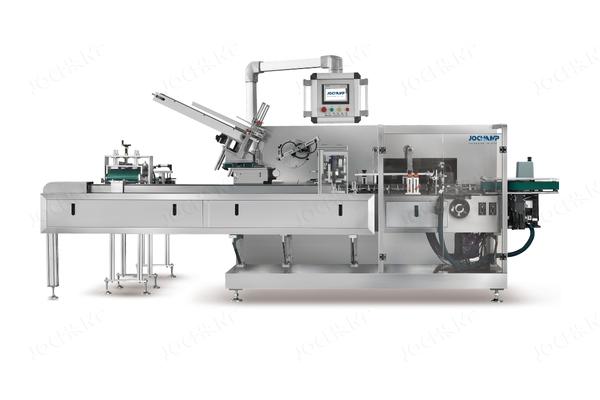

Automatic Cartoning Machine

The function of the automatic cartoning machine is to pack 100 nitrile gloves wrapped in POF film into the carton and seal it.

Automatic Case Packer

Automatic case packer consists of three functional parts: case opening machine, case packing machine, and case sealing machine.

Glove Packing Machine – Definitive Guide

This is a list of all the questions and answers about the nitrile glove packaging line. This article also includes the collaborative operation of the nitrile glove packaging machine and the nitrile glove production line, the interpretation of the packaging style, a detailed explanation of the mechanical structure, etc.

This program is suitable for: Nitrile gloves, latex gloves, examination gloves, surgical gloves, rubber gloves, and disposable gloves. Therefore, please read this article before considering purchasing automation packaging equipment.

What problems can the nitrile glove packaging line solve?

You need to invest in a nitrile glove packaging line to perfect your production process. This is what forces you to buy a packaging line for nitrile gloves.

Nitrile glove packaging line

7×23 hours work

The machine will never complain, as long as one hour a day is set aside for machine maintenance.

Clean packaging

From the production line to the packaging line, the machine can minimize personnel contact and avoid secondary pollution. All contact surfaces will be food-grade materials, able to provide the cleanest environment.

Product Consistency

Unlike manual packaging, mechanical packaging can improve the consistency of product appearance.

Improve Efficiency

Not only is the working time of 7×23 hours, but a box of 1000 nitrile gloves, using the nitrile glove packaging line can also reach 4-6 boxes per minute.

Reduce Labor Costs

It is difficult to recruit people, and the labor cost is very high. A complete nitrile glove production line can replace at least 10 manual labor.

Plan Controllability

A controllable and clear production plan can help you be organized when sales skyrocket.

What kind of nitrile glove packaging styles does the nitrile glove packaging line support?

Most of the packaging methods of nitrile gloves on the market are mainly carton packaging. The method of extracting and using is very convenient. However, due to mechanical adaptability, the direct use of carton packaging for scattered nitrile gloves will cause problems.

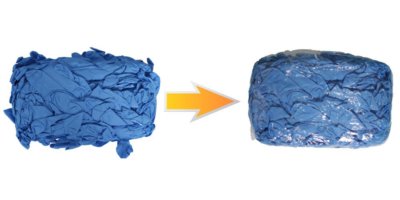

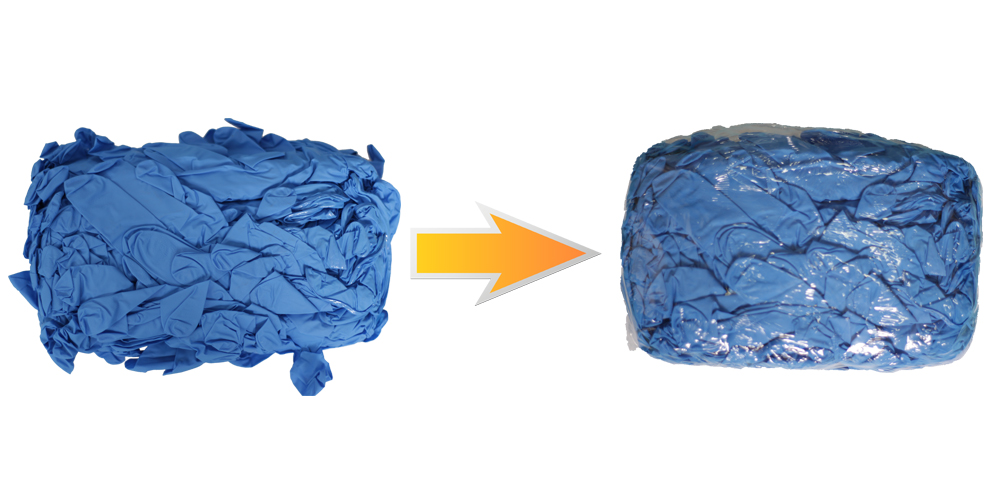

Therefore, our recommended packaging style is to use POF shrink film to pack 100 scattered nitrile gloves.

Nitrile gloves POF film packaging

Then pack the shrink-packed nitrile gloves into the carton by the cartoning machine.

Finally, we put 10 boxes (customized quantity) of nitrile gloves into the carton through the case packer.

What are the components of the nitrile glove packaging machine?

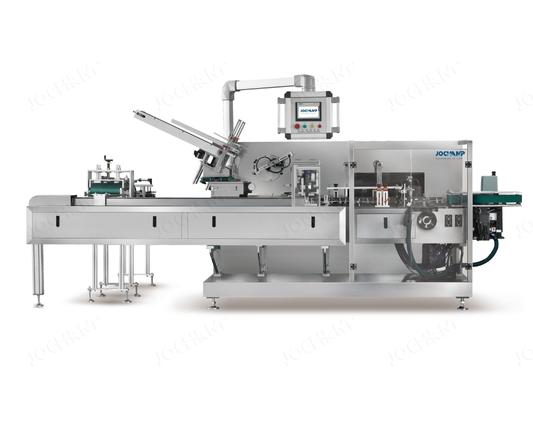

From the nitrile glove production line to the corrugated box, our nitrile glove packaging line consists of four important components: multiple transfer conveyors, automatic shrink wrap machine, automatic cartoning machine, and automatic case packer.

Multiple transit transmission agencies

The use of conveyor belts is very important, and its significance to the production line lies in several functions: additional function carriers, product transfer, product steering, and site adaptation.

In the entire transfer conveyor device, we have added two functions.

The scrap kick function in the nitrile glove packaging line can ensure that all products can be rejected when the packaging line fails.

For adaptability, we are equipped with a carton turning mechanism on the connecting conveyor belt between the automatic cartoning machine and the case packer.

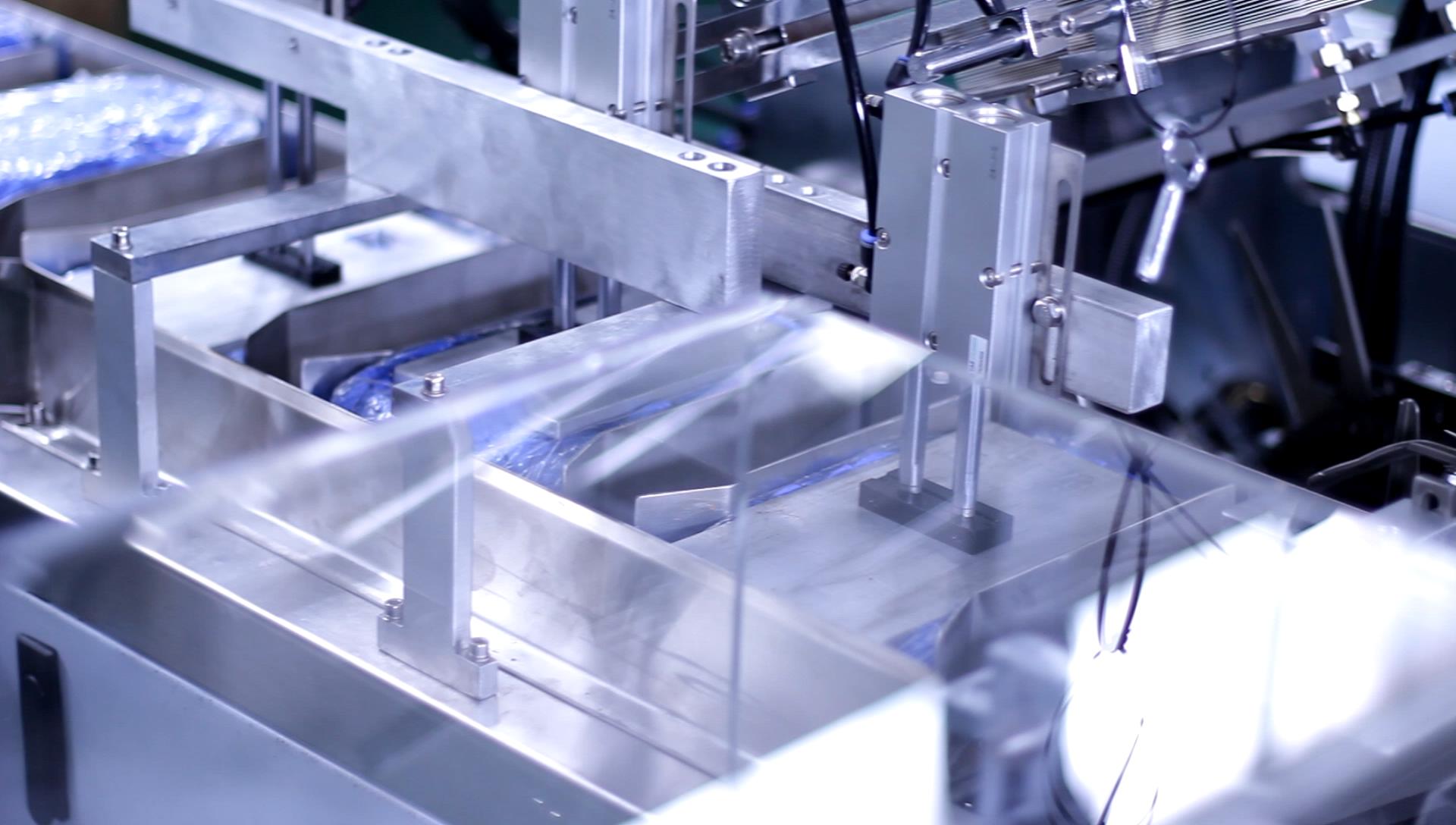

Automatic shrink wrap machine

For scattered gloves, the advantage of using a shrink wrap machine for nitrile gloves is obvious. It can make 100 nitrile gloves enter the next packaging process more regularly.

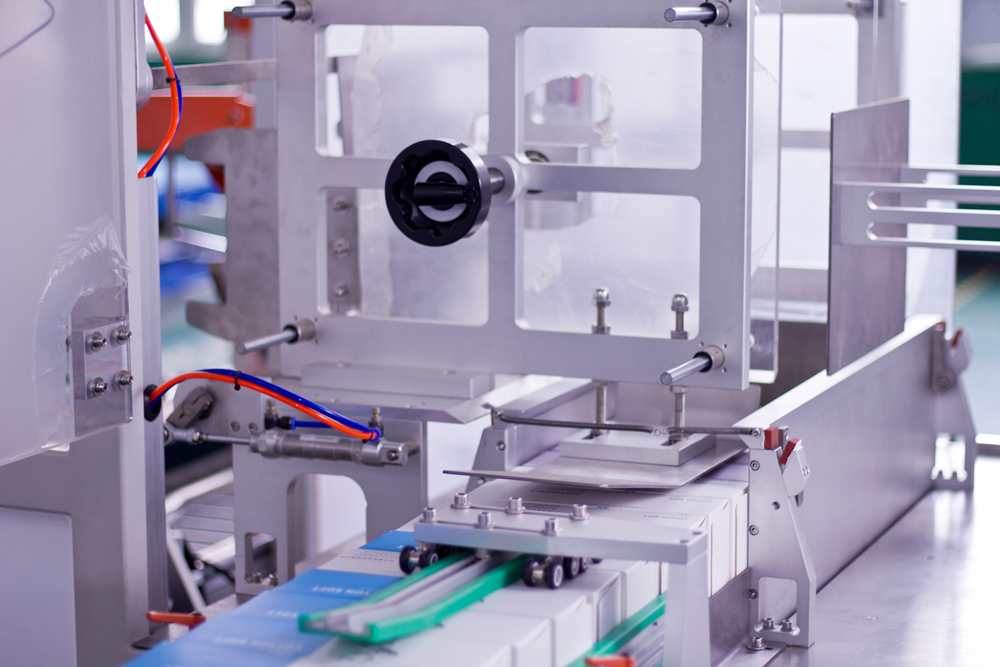

Automatic cartoning machine

The function of the automatic cartoning machine is to pack 100 nitrile gloves wrapped in POF film into the carton and seal it.

It is worth mentioning that before loading the carton, we set up a compression mechanism to compress the nitrile gloves to make it easier to enter the carton.

The closed structure of the carton is divided into the plug-in type and the sticky type. For the carton that needs to use hot melt glue to seal the box, we will be equipped with a glue spraying machine.

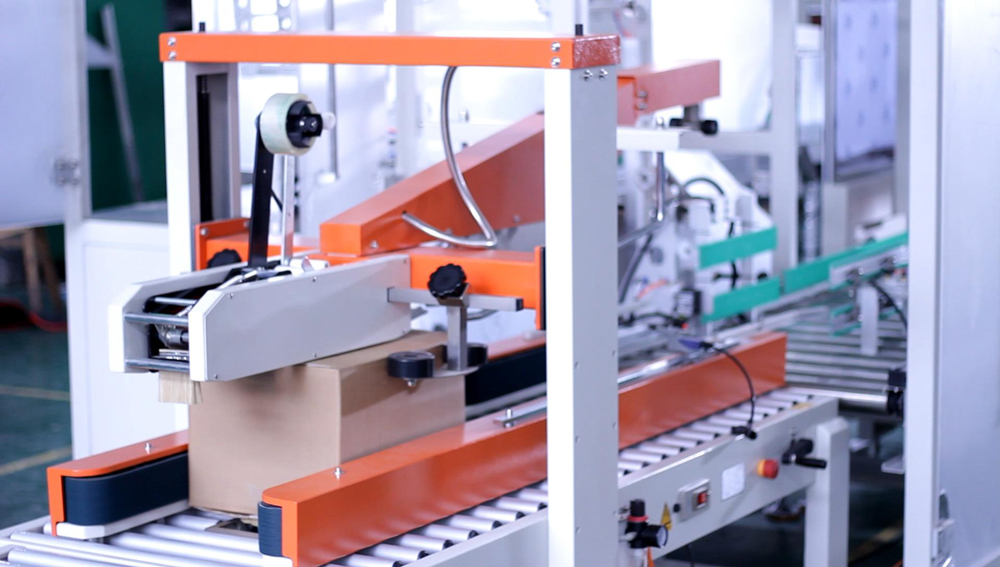

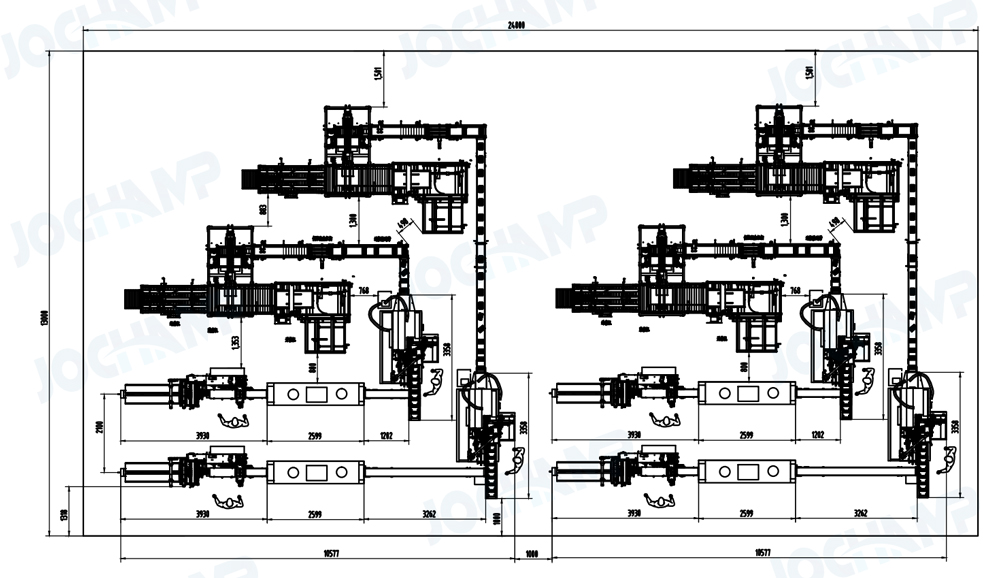

Automatic Case Packer

This is the last process of the nitrile glove packaging line, which consists of three functional parts: a case opening machine, a case packing machine, and a case sealing machine.

Usually, we use the most cost-effective case packer with a side push box.

Side push nitrile glove case packer

The speed of the boxing machine is generally 4-6 boxes per minute, which means that it can process 4000-6000 nitrile gloves in one minute.

How to automate your nitrile glove factory to the greatest extent?

Based on the limitations of the factory site, we provide customers with customized services. This service includes site layout planning, capacity planning, process planning, and packaging equipment matching based on capacity.

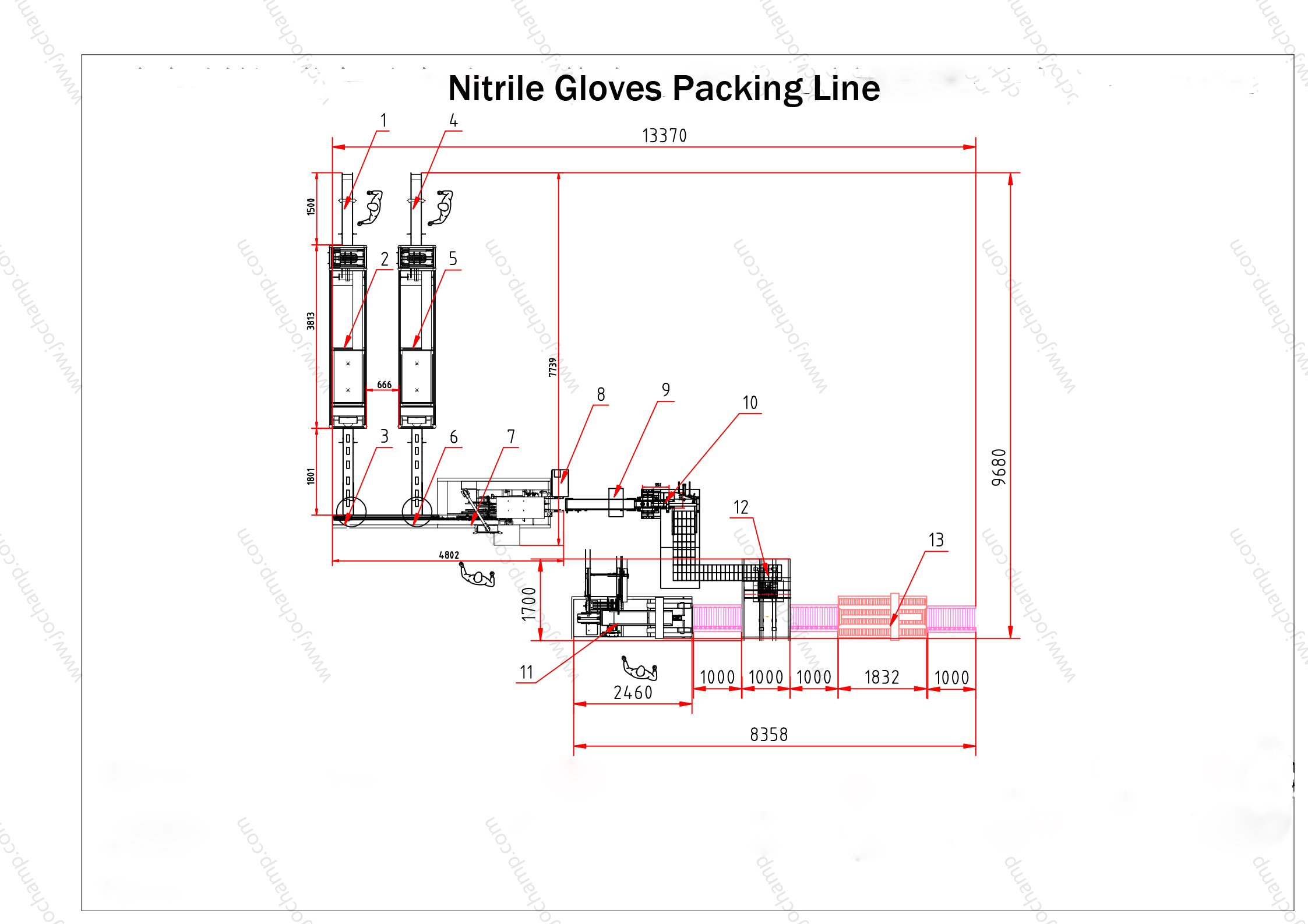

Standard nitrile glove packaging line

Generally, we recommend the standard nitrile glove packaging line. The standard speed of this packaging line is 4case/min.

- Feeding conveyor belt*2

- L bar shrink wrapper*2

- Transfer conveyor belt*2

- Automatic cartoning machine

- Glue machine

- Inkjet printer

- Carton transfer conveyor belt

- Case opening machine

- Case packer

- Case sealer

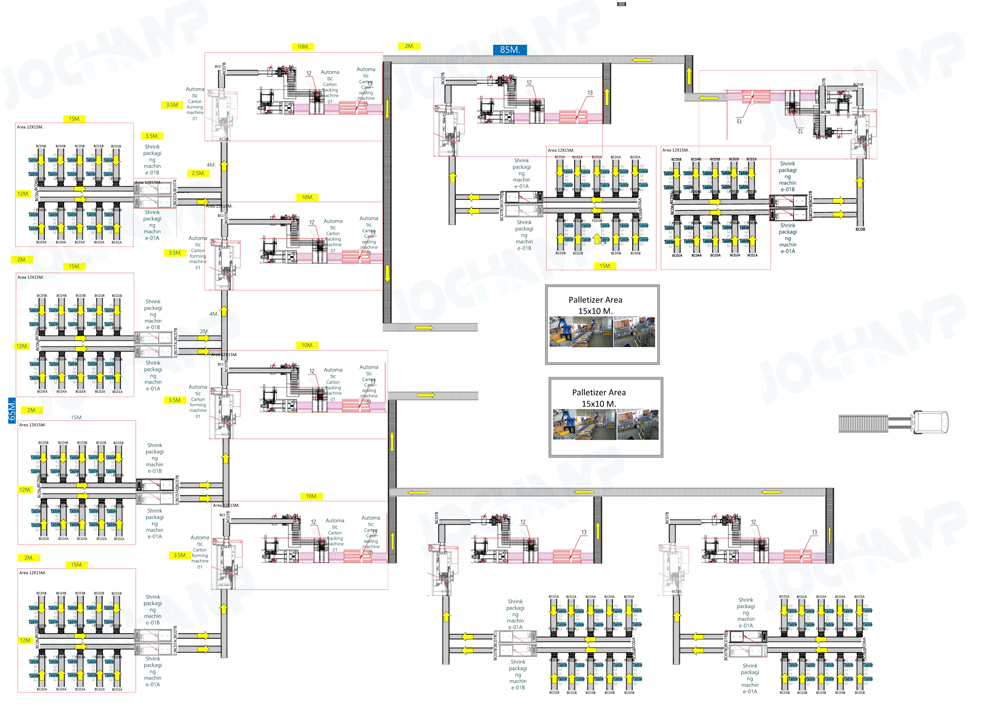

At the same time, we provide design and manufacturing of whole plant packaging solutions.

Packaging solutions for nitrile gloves designed for customers

In order to achieve benefits and maximize the ratio of cost-effectiveness to output, we have designed a new set of solutions for customers.

The picture shows the packaging solution for nitrile gloves with a manipulator at a design speed of 25case/min. This plan includes:

- Feeding conveyor belt*10

- L bar shrink wrapper*10

- Transfer conveyor belt*10

- Automatic cartoning machine. 5

- Turning conveyor belt*7

- Paper box standing mechanism*1

- Manipulator *1

- case opener*1

- case sealer*1

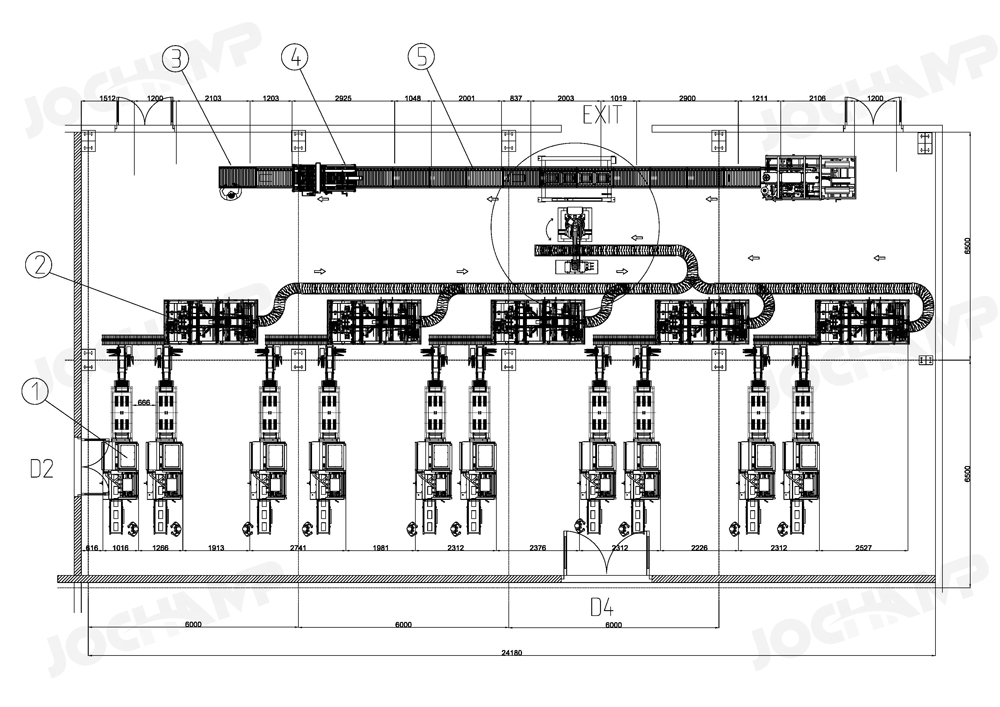

For some high-speed nitrile glove production lines, we also have a set of high-speed nitrile glove packaging line solutions.

The design speed of this high-speed nitrile glove packaging line solution is 24case/min. The project contains:

- High-speed shrink wrapper*4

- 120 Automatic cartoning machine*4

- Feeding system *4

- Transfer conveyor belt*4

- Box erecting mechanism*4

- Case packer*4

Conclusion

To this day, we are the only manufacturer that provides overall packaging line solutions for nitrile gloves. You can get the best nitrile glove packaging line according to your actual situation.