World Leading Manufacturer of Shisha Tobacco Packing Machine

Mastering the future, unmatched precision. JOCHAMP MACHINERY leads the world in Shisha Tobacco Packing Machine technology, delivering unparalleled accuracy and quality. We don’t just manufacture machines; we set the benchmark. Unrivaled performance, incomparable quality—join us in creating brilliance together! Meanwhile, we remain committed to delivering the best value for your investment!Here are the features of our equipment:

- Optimized for Shisha Tobacco

- Complete factory turnkey solution

- Years of Shisha Tobacco expertise at your service

- Cutting edge technology, high quality, low price

- Approved by hundreds of professional hookah manufacturers

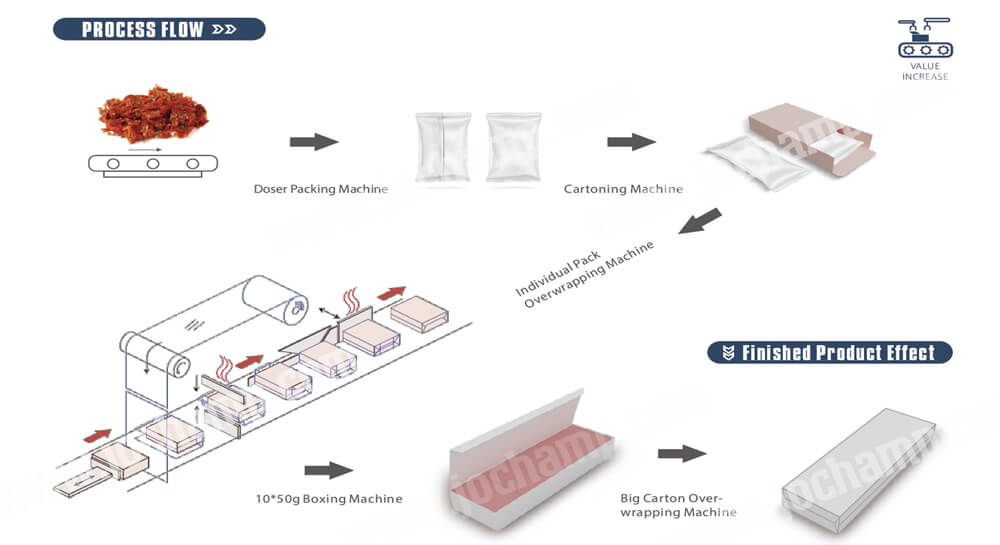

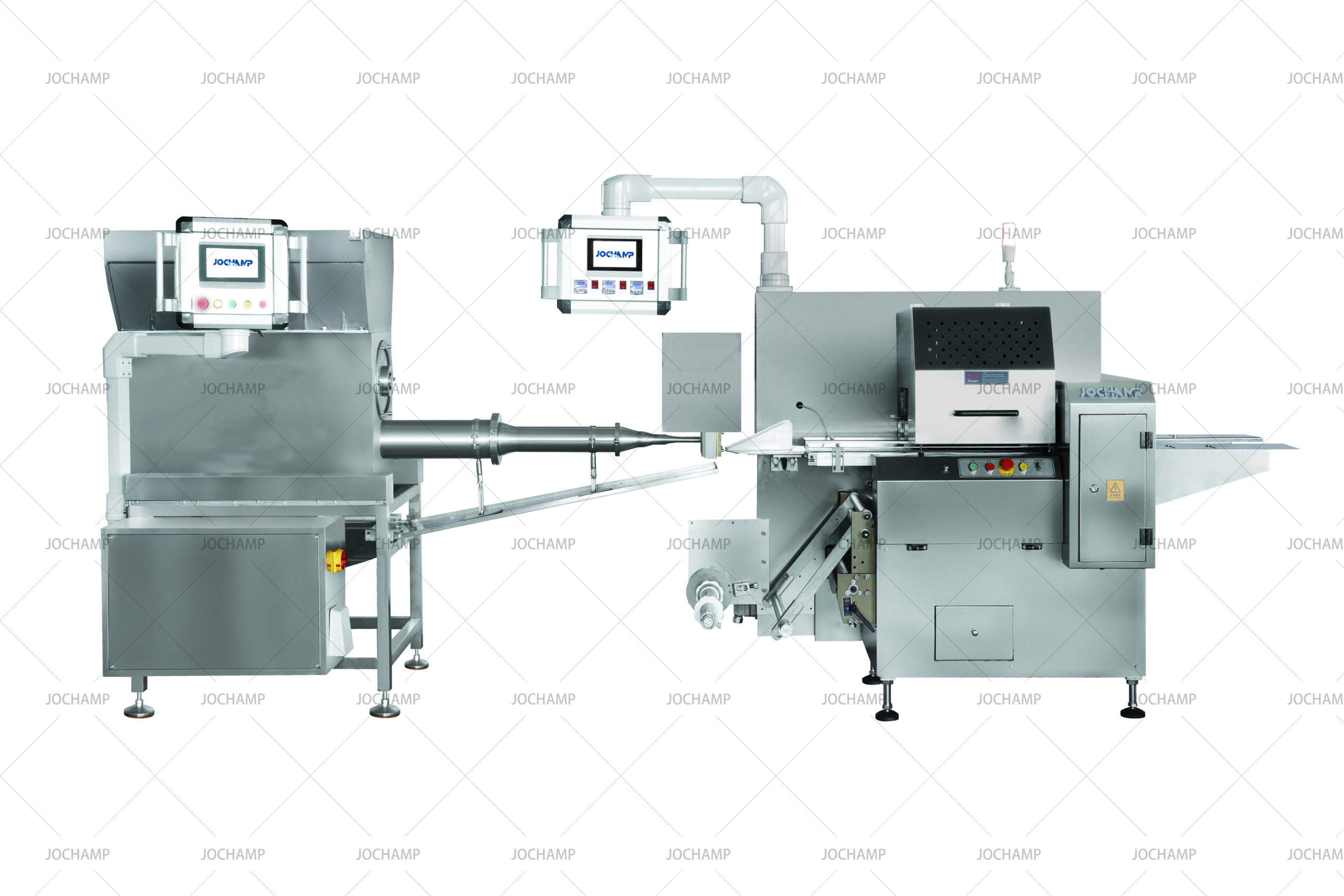

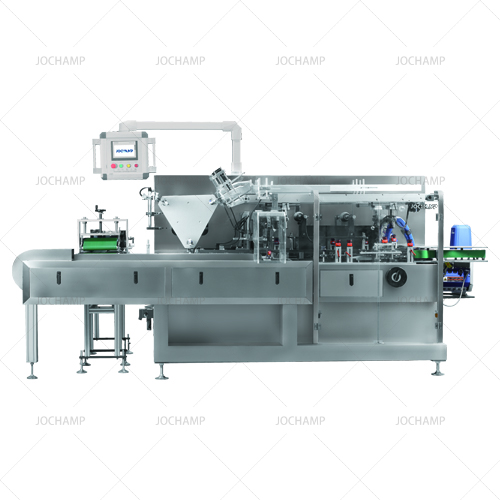

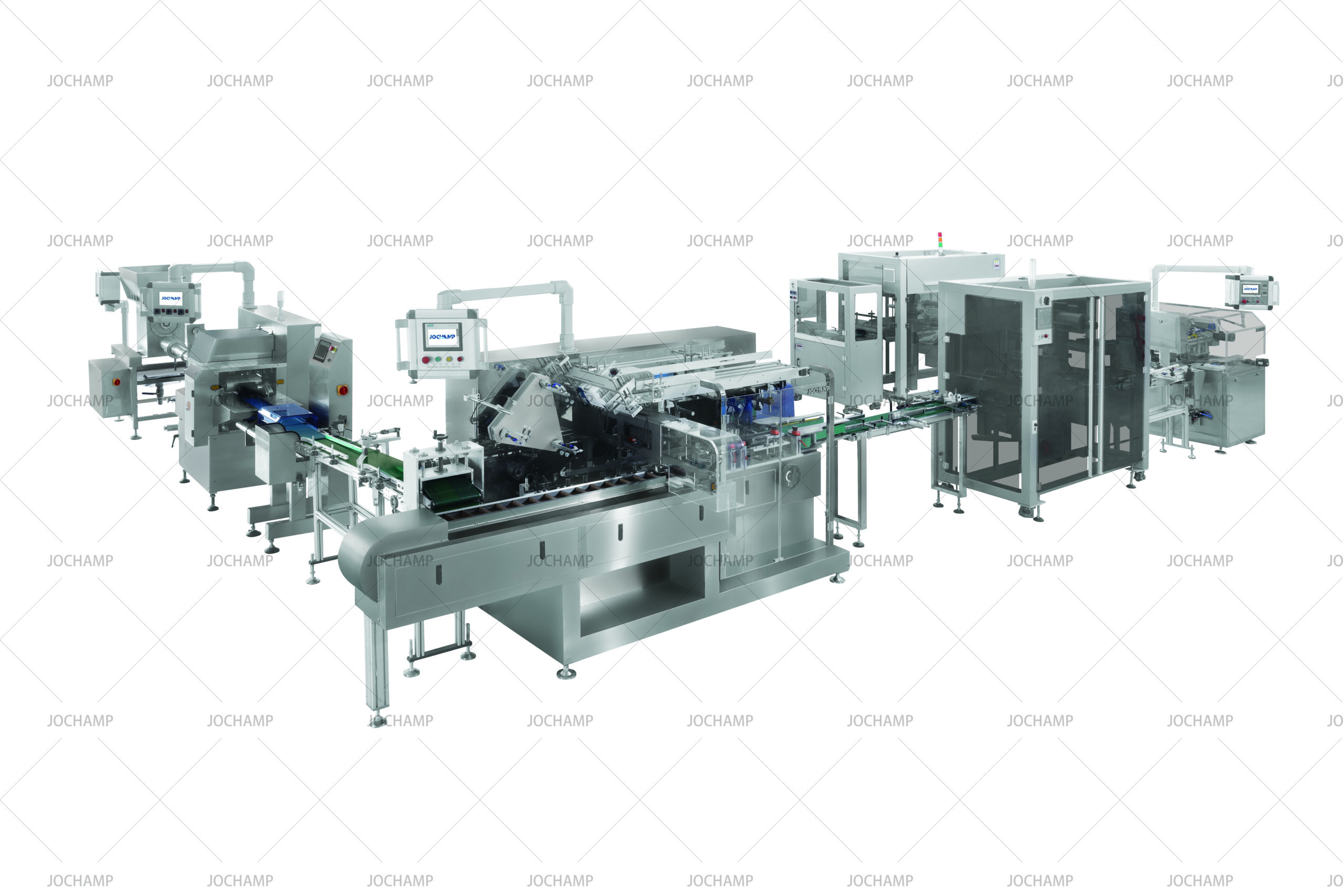

Shisha Tobacco Packaging Production Line

Jochamp provides customized packaging production solutions for shisha tobacco factories that need to be more intelligent.

- 5+ times of speed increase, the accuracy is ±1%, the constant weight

- The shisha tobacco packaging production line with mixing, extruding, cutting, and wrapping functions

- 3 types of speed specifications shisha molasses packaging machines are available: 80ppm, 120ppm, and 200pp

- mCustomize overall packaging production line solutions for hookah tobacco, especially packaging production lines for special purposes.

- Improve efficiency, clean packaging, packaging accuracy, improve quality

- Machine dedicated to shisha tobacco

- Innovative design for maximum cost-efficiency

- Equipment of all scales to suit your industrial or limited needs

Video

How the Shisha Molasses Packing Line Works

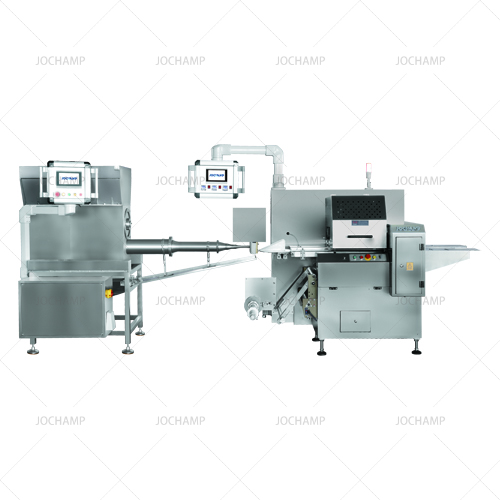

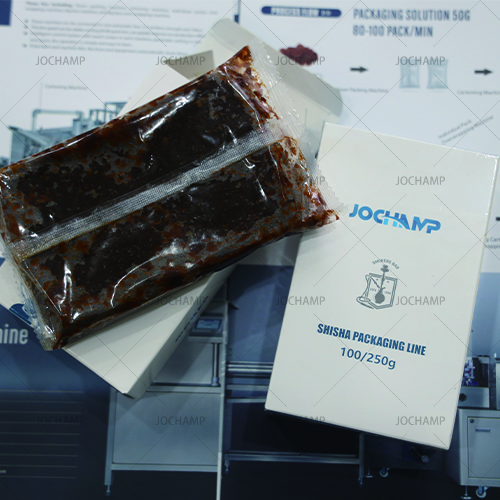

Shisha Tobacco Dosing Flow Wrapping machine

- ±1.5% weight accuracy

- Max speed: 180pack/min

- One Machine for 15-1000g

- 10 minutes cleaning

- 100% leak-proof

- Full food grade contact surface

- CE

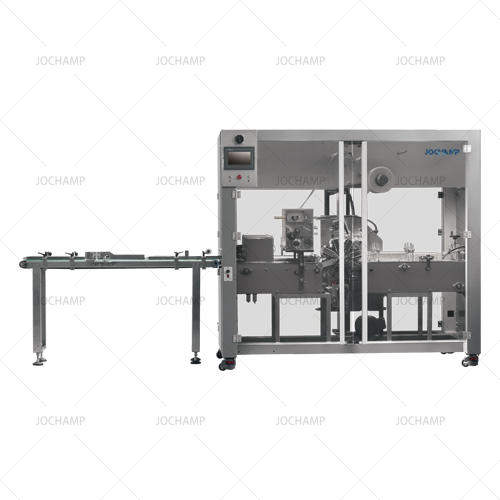

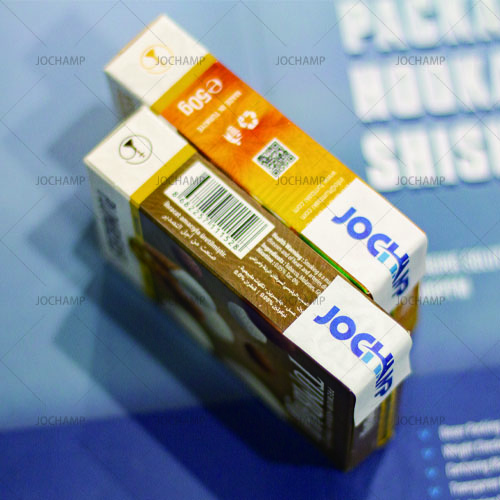

Shisha Tobacco Special cartoner

- Rotating three-tip system

- Shisha Tobacco Matching Design

- Max speed: 120 boxes/min

- Match Nordson glue sprayer

- Warehouse holds up to 1,000 cartons

- CE

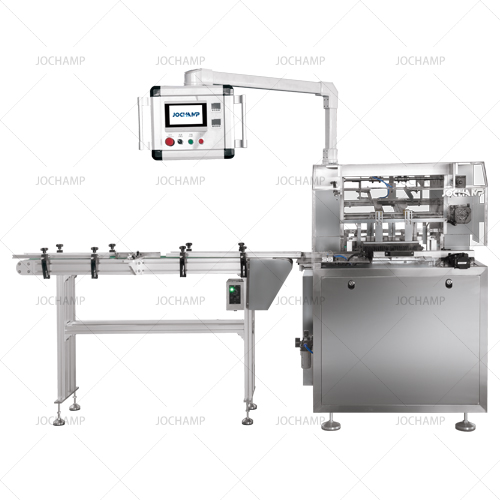

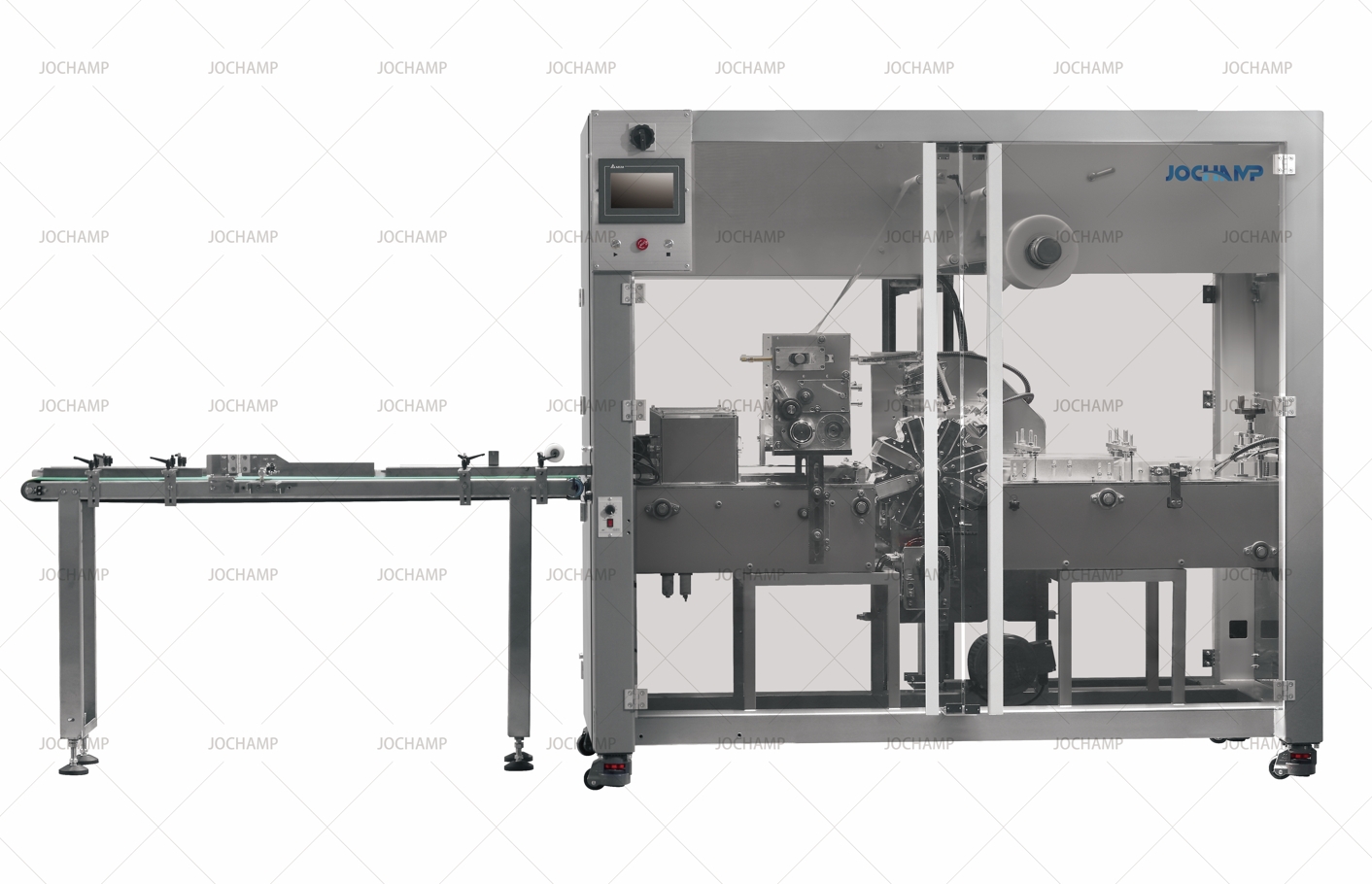

Shisha Tobacco Overwrapping Machine

- Full servo drive, more stable

- Constant temperature control system

- Max speed:120packs/min

- Fully enclosed safety door

- CE

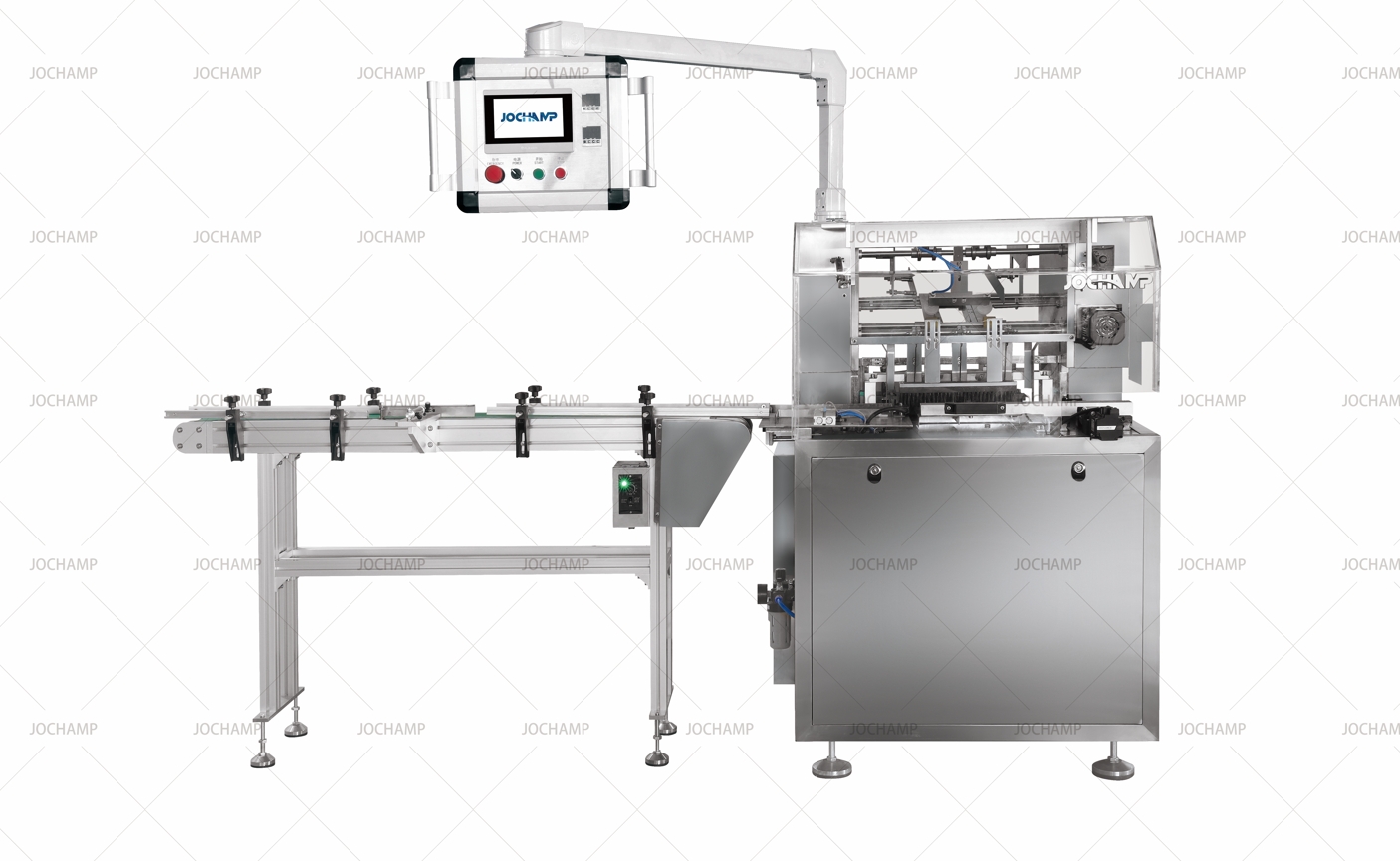

Automatic Horizontal System Cartoning Machine

- Servo intelligent box delivery

- Program-controlled dispensing system

- Standard safety door

- Prevent paper from overlapping

- CE

JOCHAMP MACHINERY- Shisha Tobacco Packaging Machine Manufacturer

-

15+ Years Industrial Experience

-

Unique and biggest shisha tobacco packing machine supplier in China

-

2-year warranty and lifetime after-sales service

-

Machine dedicated for shisha tobacco packaging

-

Customized completely package line for shisha Tabacco.

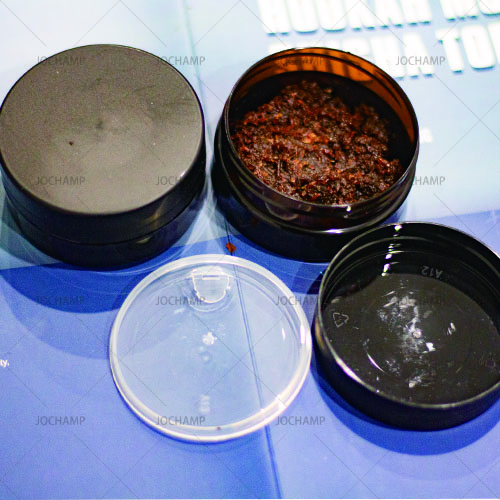

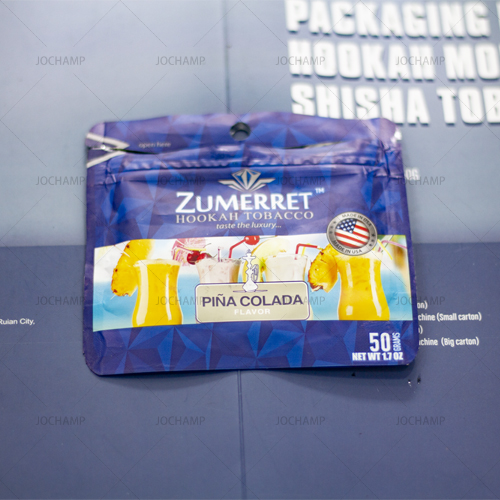

- Packaging Sample

Usually, we provide a two-year warranty service and lifetime after-sales service. For some countries where we have distributors, we provide localized after-sales service. Generally, for relatively large packaging machinery, we will send professional engineers to provide installation and training services.

From assembling to debugging to delivery, we will send related pictures and video for customers track in regular(production tracklists)

Through salesmen, customers, and engineers do some development of special requirements.

Our operating instructions will mark the maintenance methods of each component according to different machines, please follow the instructions.

Under normal circumstances, we recommend that you check the screws once a week, check the bearings and add lubricating oil every three days, clean the machine and add grease to this wheel before getting off work every day, and conduct a comprehensive inspection of the machine every month.

Our hookah molasses packaging machine support CE, SGS, IOS9001

We accept 30% T/T deposit before production and 70% T/T balance before shipment. Of course, we will be based on our customers’ available payment type, it can be discussed according to the special condition, such as EXW, FOB, CIF, CFR.

What product do you need to pack? What are their dimensions?

Shisha Tobacco Packaging Machine – Definitive Guide

With the popularity of shisha tobacco worldwide, traditional manual packaging or semi-automatic packaging machines have been unable to meet the skyrocketing demand for production capacity. Adding automatic production or packaging equipment during this time period is definitely your wisest choice.

However, special automatic machinery is more partial, and it is usually difficult to find a suitable one. This guide will discuss various uses of automatic machinery so that you can purchase the most suitable equipment for you.

1. Shisha tobacco wrapping machine with mixing, extruding and quantitative cutting functions

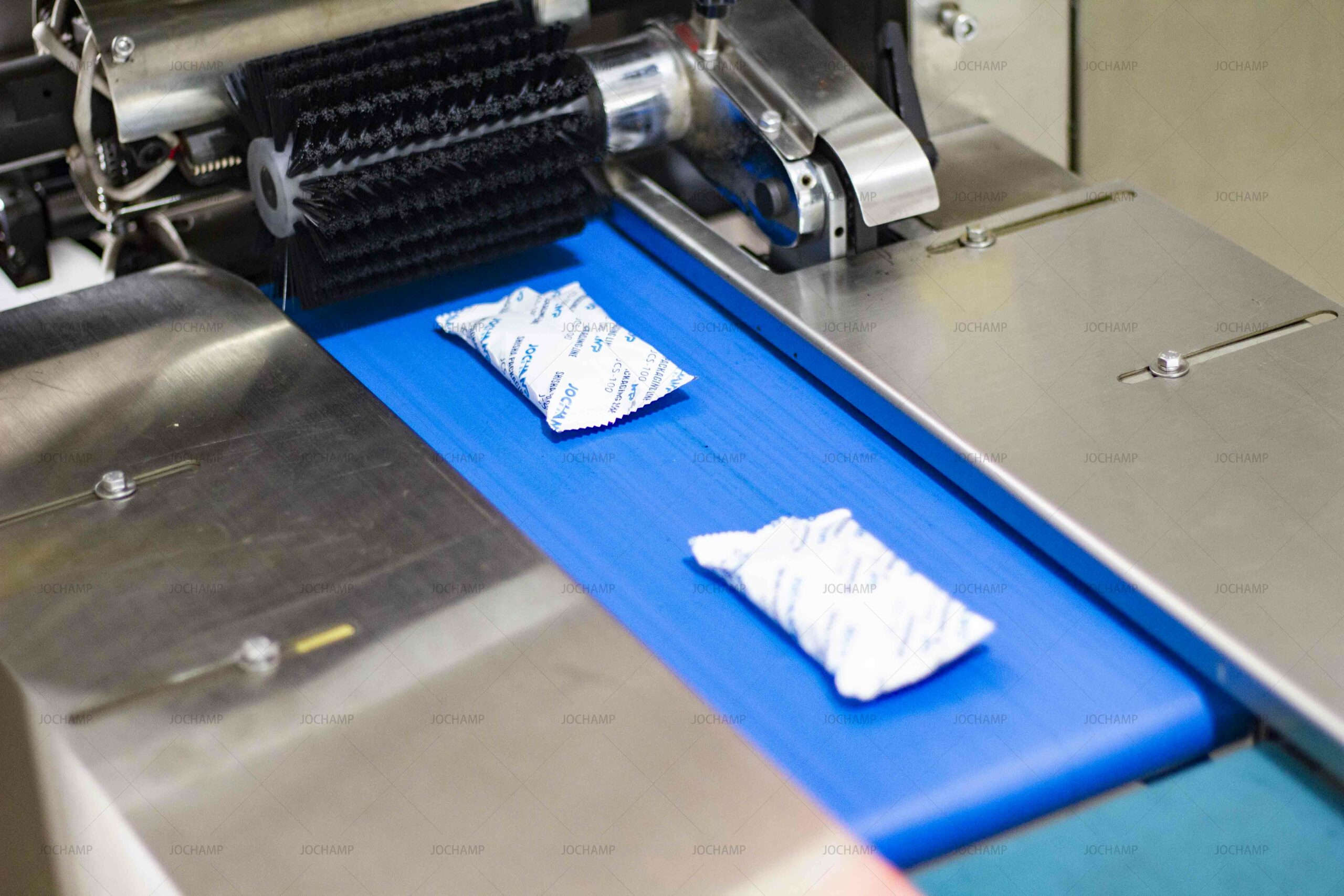

This is a packaging machine specially customized for Shisha tobacco, which can mix, squeeze, cut off and pack shisha tobacco. In the usual 50g shisha tobacco packaging application, its speed can reach up to 120bags/min, and the weight can be accurate to ±1g.

1) Component of shisha tobacco wrapping machine

I. Mixing drum

The machine has an independent mixing tank with a volume of 80 liters.

The stirring action is completed by two high-precision servo motors, which can ensure the full mixing of shisha tobacco and at the same time assist the density of the extruded part. The gearbox used in conjunction can ensure the strength of the stirring.

II. Extruder

We use a three-stage extruder to ensure the best material density while being easier to clean.

Inside the extruder, we also use food-grade 304 stainless steel to ensure the sanitation of shisha tobacco and increase the service life of the equipment.

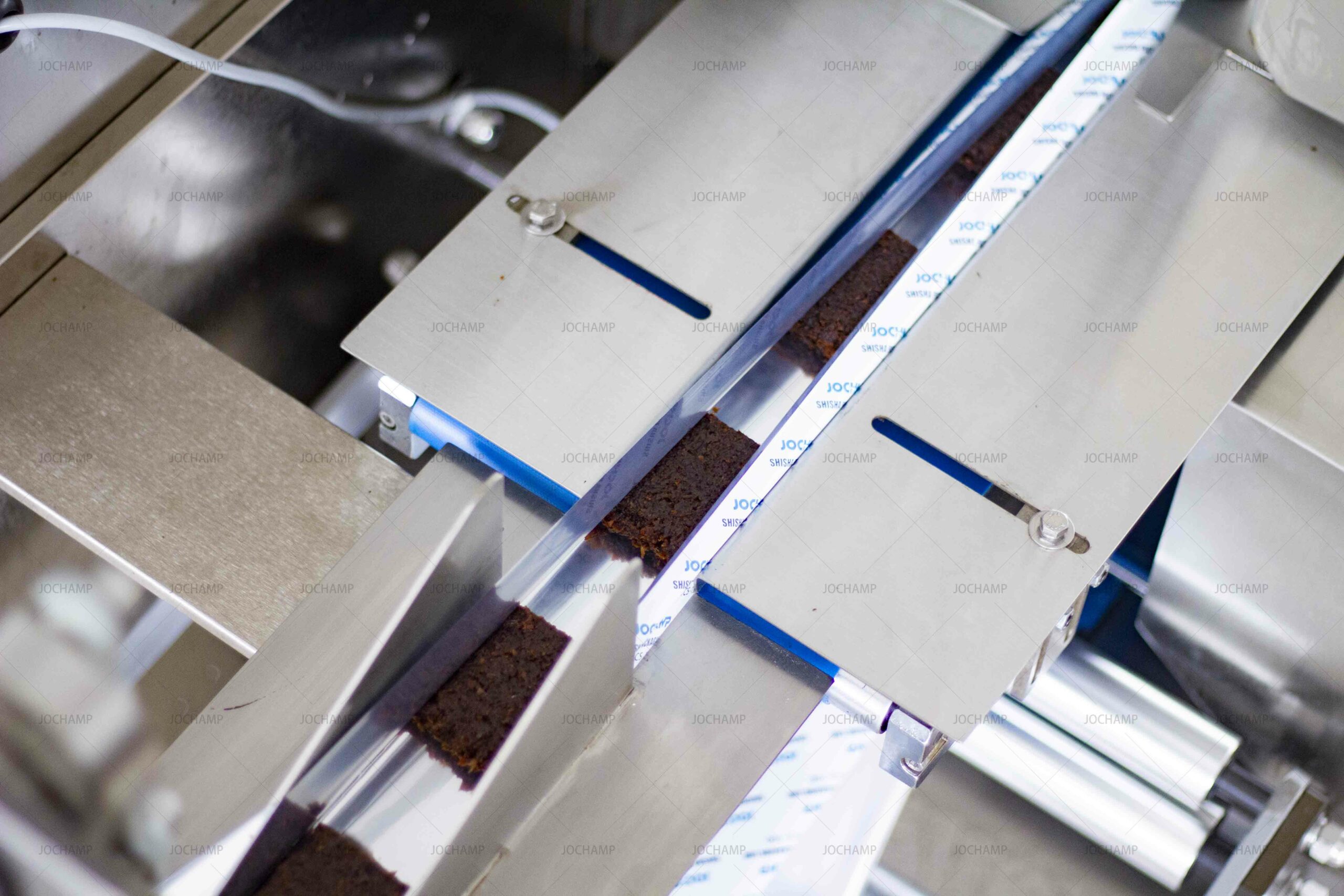

III.Quantitative cut

We use a rocker type cutter to ensure cutting speed and accuracy.

The movement of the cutter is also completed by a highly coordinated servo motor, which can better work with the front end.

IV.HMI Industrial Control System

All front-end controls can be directly through the touch screen.

V. Wrapping

We usually equip the most cost-effective 350 type Flow wrapper as the back-end connection packaging. The modified machine is suitable for 25g-250g shisha tobacco packaging.

2) Why use this machine to pack shisha tobacco instead of other machines?

In this particular field, we may have tried many different packaging solutions, but we will find that in the actual application process, equipment that is not adapted to materials with characteristics often has many failures.

I. Vertical packaging machine that cannot operate stably for a long time.

Before we developed this machine, we found that many shisha tobacco manufacturers use vertical packaging machines to package their products. After investigation, we found that there are some problems.

The speed of the vertical packaging machine is too slow. The speed of 10-30 packages per minute is obviously not enough to meet the production needs, which means that you have to buy more vertical packaging machines, occupying more space and increasing costs.

What’s more serious is that after a period of operation of the vertical packaging machine, the weight error will increase significantly. In this process, we need to continuously adjust the machine. At the same time, the scrap rate will greatly increase. These are intolerable. Compared with the shisha tobacco wrapping machine made by Jochamp Machinery, our advantage is very obvious.

First of all, our machine is equipped with a stirring, extruding, and cutting mechanism specially designed and manufactured for shisha tobacco. The coordinated work of the three servos enables the product packaging weight to always be controlled within 2% accuracy.

The back-end Flow wrapper works in conjunction with the front-end so that the maximum speed can reach 120bags/min, which is equivalent to the output of 5 vertical packaging machines!

Vertical packaging machine (VFFS)

II.Plasticine packaging machine not suitable for hookah packaging

I have to mention that many of our customers have purchased plasticine packaging machines to pack shisha tobacco.

Plasticine Packaging Machine

Through the picture, we can see that compared with the shisha tobacco packaging machine, although the appearance is slightly different, they have a similar working principle.

This can easily lead our customers into misunderstandings because although the working principle is similar, the plasticine packaging machine must not be used to pack shisha tobacco. This is because the product characteristics are different

First of all, shisha tobacco has more liquid ingredients and we need to mix them more evenly.

Secondly, the density of shisha tobacco is not as high as that of plasticine, and we need a special extrusion mechanism to operate.

2) Advantages of shisha tobacco flow wrap machine

- Higher production capacity: The stable speed of 40-150bags/min can greatly improve our production efficiency.

- Staff reduction: One person can fully operate this equipment, which means that your labour costs are greatly reduced.

- Different weight packaging: By replacing the head of the extruder and changing the data on the touch screen, we can completely switch between 20-250 grams of different weight packaging.

- Clean packaging: All material contact surfaces are made of food-grade stainless steel, and there is no manual intervention in the whole process, which ensures the hygiene of the product.

- Online packaging: Through customized connections, the machine can be used as part of the shisha tobacco packaging production line.

3) Limitations of shisha tobacco flow wrap machine

- Expensive: Dedicated machines are more expensive, which means that if you want to install this project, you will have a higher cost in the early stage.

- Land occupation: Compared with semi-automatic packaging machines or VFFS, shisha tobacco flow wrapper will occupy a larger area.

- No date printing: Due to the compact design, the machine does not support the installation of a date printer. Your product needs to be printed on the paper box. This item is under development, and the date printing function may be added later.

2. Shisha Molasses Cartoning Machine

After using plastic film packaging, generally, shisha tobacco manufacturers will pack them in cartons, and Jochamp Machinery is responding to this scenario. For different scenarios and production needs, we recommend two automatic cartoning machines to you.

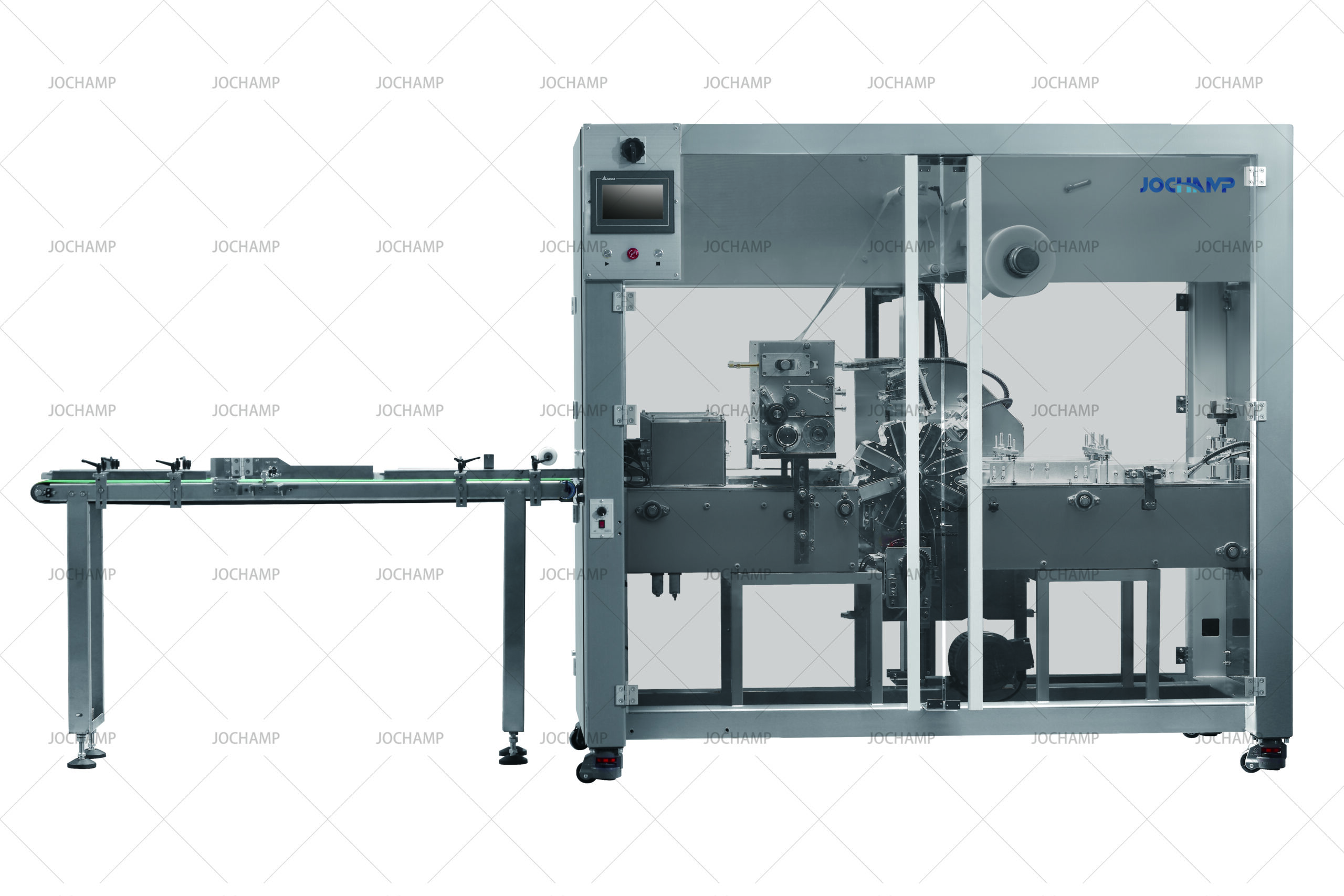

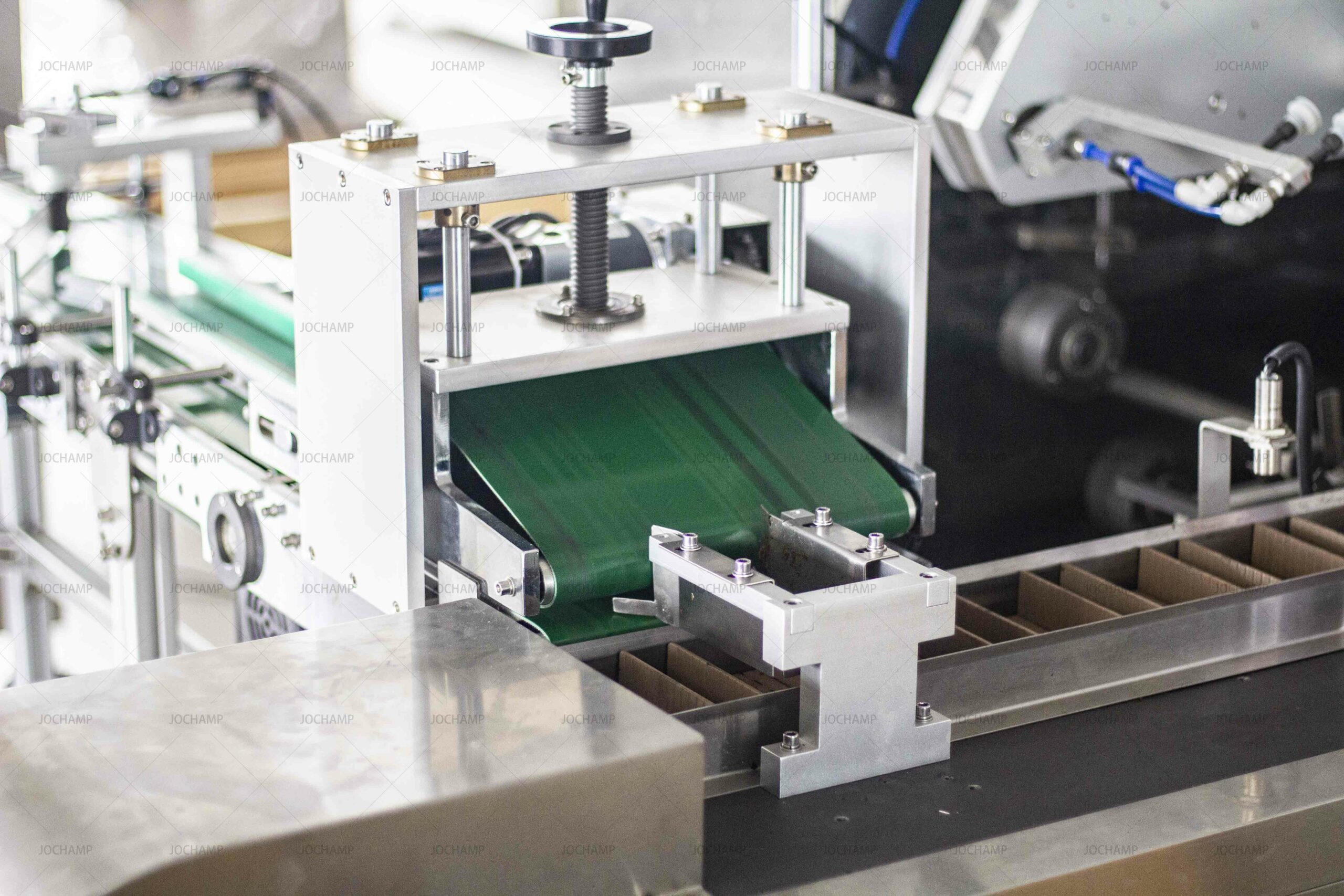

I. Intermittent automatic cartoning machine

This is the most cost-effective automatic cartoning machine for shisha tobacco. Its fastest speed can reach 100 boxes/min, and the price is only 1/4 of the continuous cartoning machine. It is a very popular machine. You can also call it a horizontal cartoning machine.

Due to its high adaptability and wide range of applications, this machine is very popular in the market. It is our most common type of cartoning machine.

As shown in the figure, the suction box mode of the intermittent cartoning machine is up and down movement, and the pushing material is a single pushrod direct push, so the movement of the entire machine is restricted by the suction box and the material pushing parts. During the transportation of each product, It needs to be paused once, so we call it an intermittent cartoning machine.

Advantages of intermittent cartoning machine

Compared with the continuous cartoning machine, the advantages of this machine are:

- Lower cost.

- Smaller space occupation.

- Easier operation.

- Later maintenance costs are lower.

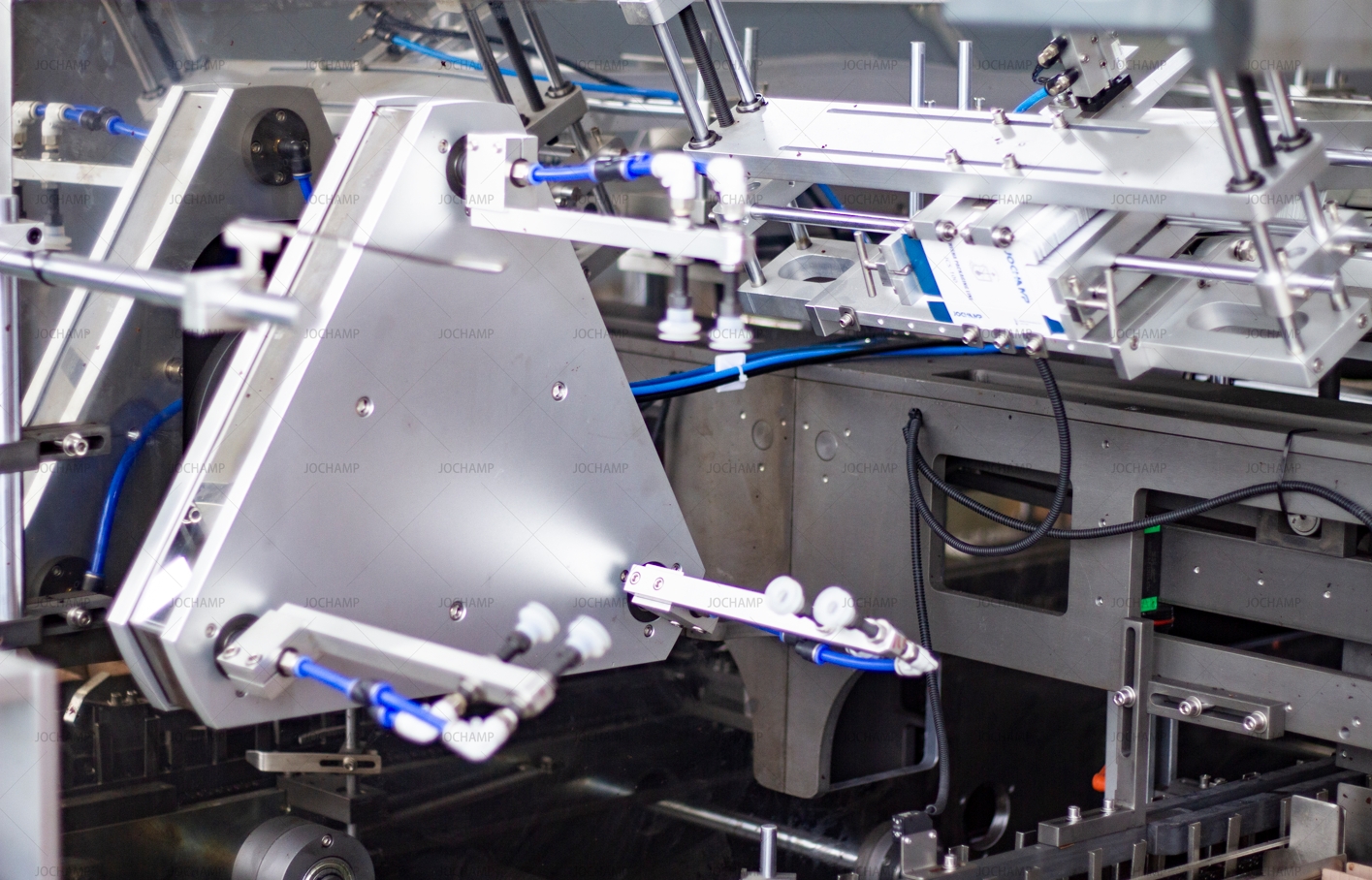

II. Continuous cartoning machine

Continuous cartoning machines are more common in some online packaging solutions because the speed of the machine matches the shisha tobacco flow wrapper.

Of course, you can also call it a high-speed automatic cartoning machine. This machine is generally only suitable for products with a relatively regular shape, and scattered products can easily make the machine unstable. It must be mentioned that its fastest speed can reach 100-500 bags per minute, which is not possible with intermittent cartoning machines.

As shown in the figure, thanks to the rotary suction box mode and the continuous operation of multiple pushrods, the working mode of the machine can be continued uninterrupted, so we call it a continuous cartoning machine, and its speed is also Hence the benefits.

Application of automatic cartoning machine in the shisha tobacco industry

Usually, we will recommend to you an automatic cartoning machine solution for online packaging, because it helps improve the stability of the machine while reducing labor costs and increasing productivity.

We generally recommend two more stable online packaging transfer automatic feeding solutions to customers.

The first type: lower cost linear conveyor belt + servo feeder

This automatic feeding method can be connected to the shisha tobacco wrapping machine in the easiest way. The back end of the linear conveyor belt is equipped with a servo drive, which can cooperate with the movement of the machine storage bin so that the shisha tobacco of the pillow pack can evenly fall in each storage bin. This automatic feeding method is recommended by us because of its low cost, simple use, and no special settings.

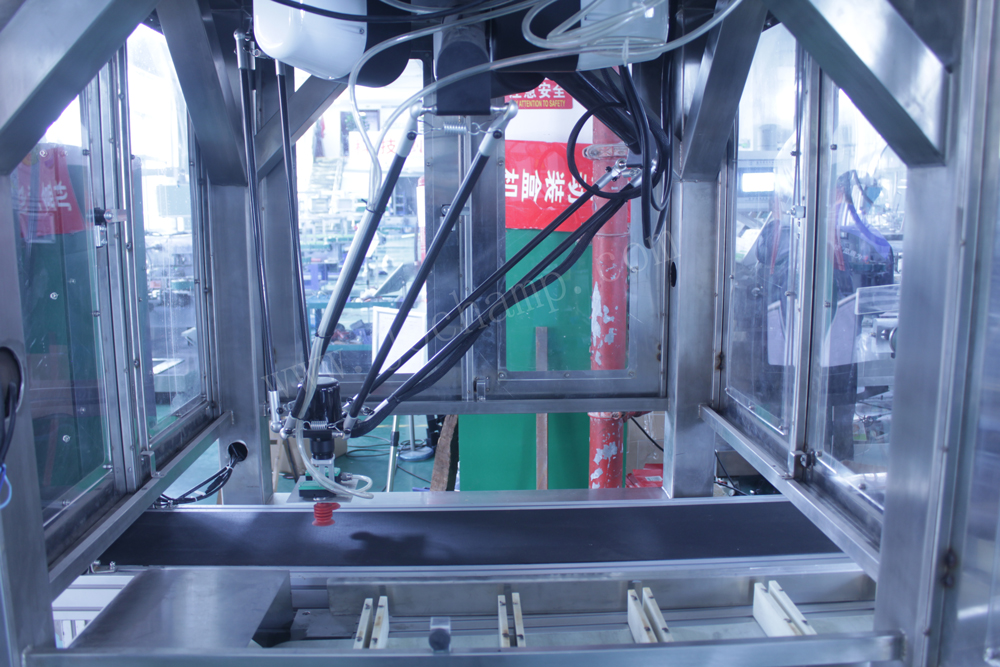

The second type: intelligent manipulator transfer system

The intelligent manipulator turning system is very expensive, but it has excellent stability. Usually, the robot is equipped with a vision system, which can correct the position of the product through photos. It can also be used as a basis for detecting the quality of the front-end packaging.

The intelligent manipulator transfer system is more complicated and requires certain maintenance capabilities. Generally, we do not recommend it to start-up companies.

3. Nargile overwrapping machine

In the tobacco industry, there is an unwritten rule that almost all cigarettes in carton packs will be packed with a layer of BOPP film on the surface of the carton. The shisha tobacco industry is no exception. We can see that most shisha tobacco in carton boxes will have this layer of plastic film packaging.

This is because of the transparency and easy tearing characteristics of BOPP film, so almost all tobacco practitioners choose this kind of packaging. On this layer of film, attaching an easy tear line also makes the whole package easier to open. Under these premises, we have three BOPP overwrapping machines for you to choose from. They have different functions and different speeds.

The first type: rotary overwrapper

This is the cheapest overwrapping machine, but its speed can only reach a maximum of 50-60 boxes/min. The machine is easy to operate, and for single-size shisha tobacco, it can almost work when plugged in.

The second type: high-speed flat push overwrapper

The machine also only supports single-pack shisha tobacco packaging, but thanks to the flat push-type fast feeding, its speed can reach up to 120 boxes/min. At the same time, through the compact design, it has a smaller footprint and more convenient mold adjustment.For a single specification of shisha tobacco, it can also work when plugged in.

The third type: multi-package overwrapping machine

Usually, the rear packaging of shisha tobacco includes 10 packs of multiple packs. This kind of packaging is beyond the scope of the above two packaging machines, and this machine is needed. The machine has a flat push structure, and its speed is limited by the product. Generally, the speed of packaging shisha tobacco is 30 packs/min.

4. Shisha Tobacco Carton Packing Machine

This carton packing machine is specially designed and manufactured for shisha tobacco packed in 10-pack cartons.

The speed of the machine can reach up to 22boxes/min. Because of some policies, the machine currently only accepts customization, there is no spot, and the price is relatively expensive.

5. Advanced version: Hookah Shisha Packaging Production Line

We provide customized packaging production solutions for shisha tobacco factories that need to be more intelligent. The solution will include the following multiple optional features:

1) Different forms of packaging machinery combination.

The different packaging styles of the product and the demand for production volume determine the combination of the machine. We can combine different packaging machinery through some technical means, including shisha tobacco flow wrapper, overwrapper, cartoner, case packer, and other packaging machinery. These combinations will be very diverse, and we will match the best combination by balancing cost-effectiveness and speed matching.

2) Quality inspection system

Packaging quality and product hygiene are very important. In the packaging process, we can add some testing functions to ensure packaging quality and product hygiene. Optional configurations include a metal detector, weighing system, visual inspection system.

3) Label and printing system

In machine applications, we can choose to equip labelling and printing functions throughout the process. According to different needs, the configurations that can be selected include: stamp tax labelling, sealing labelling, source code printing, date printing, etc.

4) Transit system

The adaptability design of the plant area is also a crucial link. We use the transfer system to better adapt the factory. Inadaptable design, we most commonly use these transfer systems: linear transfer conveyor belt, flexible transfer conveyor belt, intelligent robot hand transfer system, servo transfer system.

6. How to obtain your shisha tobacco packaging production line solution?

We have some practical cases for your reference at any time, but in the case of some special needs, we need to design another set of plans, all of which are free before placing an order. But we need some steps:

First of all, indicate that your needs are important, which include output requirements, plant floor plans, product packaging styles, functional requirements, etc. We will evaluate all your requirements within 36 hours and issue a solution drawing and preliminary quotation. Then, we have an in-depth discussion, and after all the details are implemented, we enter the production.

Under normal circumstances, we will ask customers to send samples, but because shisha tobacco is more expensive, this shisha tobacco cannot enter the market after our test machine, so for this product, we ourselves store shisha tobacco with normal formula. Can be used for test machines.

If your shisha tobacco formula is not within the normal range, such as some dry or wet, please send samples.

7. Technical compliance of shisha tobacco packaging machine

Usually, for parts that are in direct contact with shisha tobacco or packaging materials, we will use stainless steel and some food-grade materials. In some areas with safety risks, we will install protective shields as much as possible.

This ensures that the machine meets hygiene and safety standards. In addition, all our shisha tobacco packaging machines manufactured and sold are in line with ISO, CE, and SGS certification.

8. Conclusion

For a more stable production, you should choose to purchase a packaging machine suitable for shisha tobacco. You can choose to use different packaging equipment as a packaging production line.