Jochamp Machinery- Provide Best Shrink Wrap for Bath Bombs

- Packaged In Single Or At Will.

- PLC is equipped to control the Unit to reduce failure points.

- The speed can be frequently varied but not classed.

- The shrink wrapper is produced according to Japanese techniques, all electrical elements are imported

- A faster machine that can combine the steps of bagging bath bombs, sealing the bag, and shrinking the bag.

- Our shrink wrap machines have severed more than 100 bath bomb manufacturers around the world.

- The speed of the machine has increased by 2-10 times.

- It is better than the intermittent shrink wrapper in the corner processing.

- So far, it is the most ideal shrink wrap solution for bath bombs

One Stop Solution Shrink Wrap for Bath Bombs

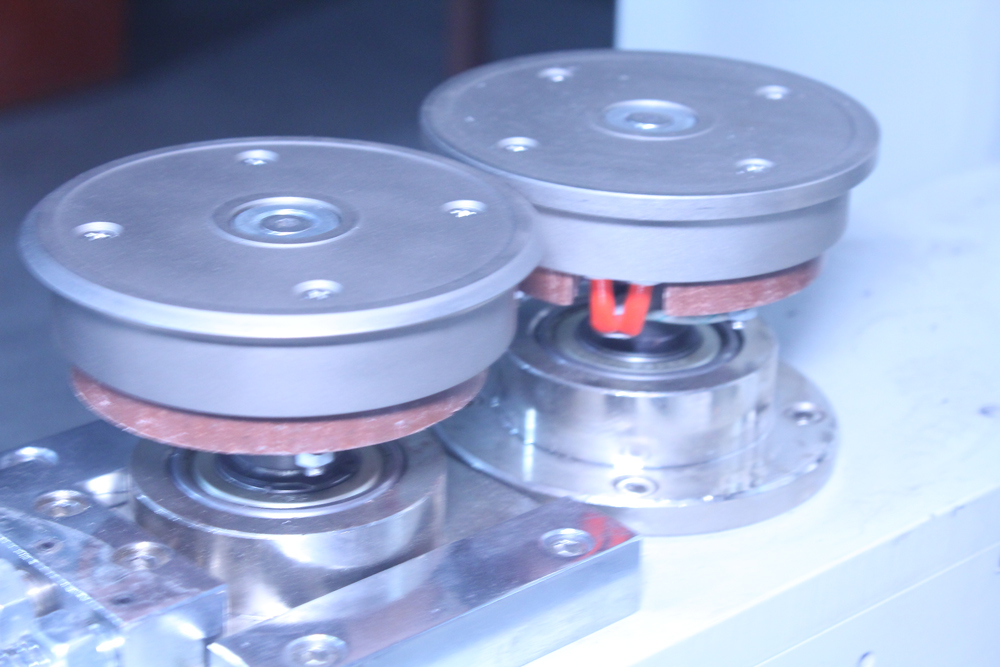

- Main Components

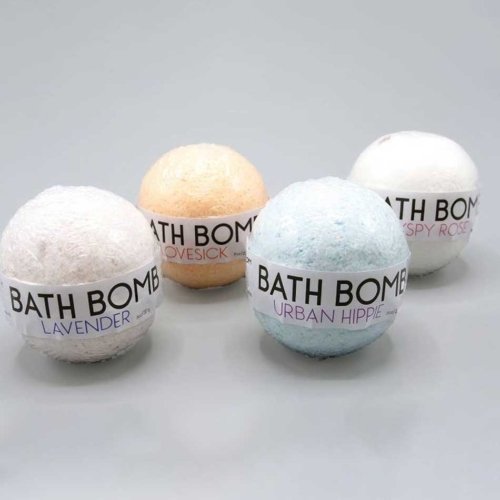

- Packaging Sample

of course, we can design, manufacture and install automated packaging lines based on customers’ products, budgets, factory floor plans, etc.

Unlike the standard machine, if the machine involves customization, the price will be different. So before getting the final quotation, you need to provide exact product information, speed requirements, etc.

Single-layer POF shrink film thickness 0.015mm=15 micron (Only mosquito coils need to use PVC shrink film because the chemicals in the mosquito coils will react with POF)

It can be used, but due to the shrinkage characteristics, it is not recommended to use a film with too high printing fineness.

It is possible but not recommended. The packaging effect of PE film is too poor, and the material will be sticky.

Film width = (product height + product width) x2 +100mm

The linear speed of the machine is 32 meters/min, and the speed generally converted into a product is approximately equal to 80-130pcs/min.

Bath Bombs Shrink Wrapping Machine – Definitive Guide

As the demand for Bath bombs grows, manufacturers of Bath bombs are facing a problem. Traditional manual packaging and semi-automatic machine packaging can no longer meet actual production needs. We need a faster machine that can combine the steps of bagging bath bombs, sealing the bag, and shrinking the bag. The ZWG-590 high-speed shrink wrapper designed and manufactured by Jochamp Machinery can completely solve this problem.

And in the past three years, we have provided our machines to more than 100 bath bomb manufacturers around the world. In this article, we will discuss the structure, principle, advantages and disadvantages of the machine.

let’s start.

1. What are Bath bombs shrink wrap machines?

This is by far the most ideal solution for bath bombs. The high-speed heat shrink wrapping machine uses POF heat shrinkable film single-layer roll material, wraps the film on the surface of the product and shrinks the product through the hot air channel so that the product is beautiful, anti-theft, moisture-proof, dust-proof and firm.

Based on the traditional intermittent shrink wrapper, Jochamp Machinery has developed and manufactured a high-speed continuous shrink wrapper. The speed of the machine has increased by 2-10 times. It is better than the intermittent shrink wrapper in the corner processing.

2. Why do you need bath bombs shrink wrapping machine?

For now, there are still many manufacturers of bath bombs that use traditional manual or semi-automatic methods to package products. Usually, we need the following steps to package bath bombs:

This way of packaging bath bombs is very suitable for individuals, but for bath bomb manufacturers, it means high costs. Moreover, through this kind of manual packaging, due to uneven heating and difficult control of the bag length, your shrink packaging will reduce the aesthetics of your products.

Carefully observe the shrink packaging in the picture, you will find that the prominent corners and very obvious edge sealing lines affect the visual effect of the entire product.

For beauty products, this will lead to low customer acceptance, distributors’ dissatisfaction with your products, and a decline in sales.

The high-speed shrink wrap machine perfectly solves these problems.

In the actual application process, the speed of the machine can reach a stable 7200/H, which is more than 20 times the speed compared to manual. This will mean that buying this machine can at least save you more than 20 labour costs. Relative to the price of this machine, you can earn back the corresponding costs within one month.

Bath bombs automatic feeding and packaging system

Using the high-precision operation of the mechanical system and the uniform heating of the heat shrinking furnace, we have greatly improved the aesthetics of the bath bombs. More compact packaging can make bath bombs less fragile. At the same time, as consumers, of course, they will choose more beautiful products.

3. The benefits of using shrink wrap for bath bombs.

POF film shrink packaging is one of the most ideal packaging methods for bath bombs. The advantages of using POF shrink packaging are as follows:

- Skin packaging

A major feature of shrink packaging is that it can highlight the shape of the product, which allows consumers to see your product more intuitively.

- Breathable

Before heating the shrink film, we need to make some pinholes in the shrink film, which is to discharge the gas during the shrinking process. At the same time, these small vents can make the smell of the bath bombs escape the package and let it on the shelf More attractive to consumers.

- Protective packaging

The correct packaging of bath bombs can make your bath bombs have a longer shelf life. The use of shrink packaging can make bath bombs less fragile and able to withstand greater external pressure while protecting the product from moisture.

- Cut Costs

POF film is one of the most economical packaging methods. The use of shrink packaging can effectively improve your cost-effectiveness.

4. The advantages of high-speed bath bombs shrink wrap machine.

As an alternative to manual packaging, what can high-speed bath bombs shrink wrap machine bring you?

- Planned Production

Unlike manual packaging, you can easily formulate your production plan on the automatic packaging machine. Everything is clear.

- Increase production

It takes 10 seconds for a skilled worker to pack a bath bomb, which is 360 in an hour. A high-speed bath bombs shrink wrapper with a double cutter system can pack 120 pieces per minute, and 7200 pieces per hour. Almost 20 times faster!

- Cut Costs

Assuming that your workers are paid 20 U.S. dollars per hour, work 8 hours a day, and each person packs 360 bath bombs an hour, then 20 workers are required to pack 7,200 bath bombs in one hour.

The cost you need to spend every hour is 20*20=400USD, and eight hours a day=3200USD. According to the pricing of our standard machine, you will earn back the cost of this machine within one week.

- Improve product beauty

The result of high-precision machinery is thinner edge banding lines and smaller corners. The specially designed heat shrinkable channel can make the shrink film heat more evenly so that the aesthetics of the packaging can be improved.

- Tamper proof

The unified effect of automatic equipment packaging can effectively help consumers distinguish the authenticity of the product, which is one of the simplest anti-tampering methods.

5. Limitations of the high-speed shrink wrapper

Of course, you will also encounter the following problems when buying a high-speed shrink wrapper:

- Professional

You need to be trained staff to operate, set up and maintain the equipment.

- Land occupation

A standard high-speed shrink wrapper is 7 meters in length, and you must reserve enough space before purchasing this equipment.

- High initial cost

The initial cost of setting up a packaging machine on your production line is relatively high.

6. Components of high-speed bath bombs

High-speed bath bombs shrink wrap machine is equipment composed of electrical, mechanical and light components. They are all combined to work together in a way to effectively generate, transform or utilize the mechanical energy generated by the system.

A standard high-speed shrink wrapper consists of hundreds of parts, but here we will introduce you to the main components so that you can better understand this equipment.

Main Component:

- Control System

- Feeding system

- Sealing and cutting system

6.1 Control System

The control system of the high-speed shrink wrap machine is mainly composed of two parts, HMI man-machine industrial control and electrical part.

Control Panel

Most of the settings can be achieved directly through the control panel, including speed matching, data display, printer communication, etc. At the same time, through three sets of high-precision servo drives, we can achieve more refined functions.

6.2 Feeding System

The bath bombs automatic feeding system is mainly composed of two parts: a silo and a feeding claw.

Automatic feeding bin for bath bombs bath bombs feeding claw

The two feeding mechanisms are respectively driven by two independent servo motors, controlled by PLC, and work in coordination.

6.3 Sealing and Cutting System

This part consists of two parts, the horizontal seal and the vertical seal.

Longitudinal sealing knife part Horizontal sealing hob part

These two parts are driven by two independent servo motors, which can achieve integrated control. We have applied a special coating treatment to the surface of the sealing knife to make the bag seal stronger and the sealing line thinner and the coating can effectively extend the life of the sealing knife.

7. How to comprehensively increase the yield of your bath bombs?

With the increase of your business volume, purchasing high-speed shrink wrappers can only improve your product packaging links, and the efficiency issues in the production process still need to be improved. In this chapter, we will recommend equipment that can help you increase the output of bath bombs.

let’s start.

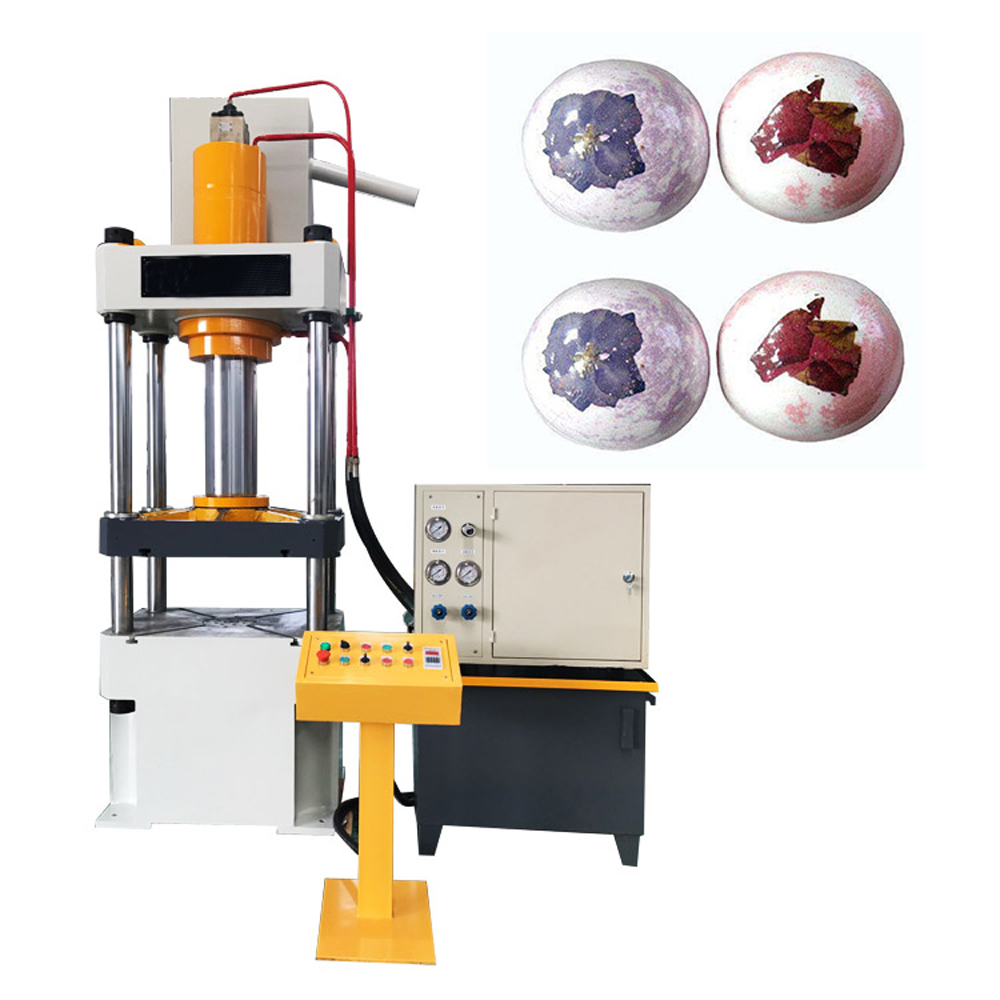

7.1 High speed bath bombs press machine

The traditional pressure or voltage bath bomb press machine can no longer meet the production needs of bath bombs manufacturers in terms of speed and pressure range. We use oil pressure to suppress the bath bombs, making the bath bombs stronger and not fragile.

At the same time, by changing the mold, you can suppress more than 20 bath bombs at a time. This machine can reach 6000PCS/H at the fastest according to product size and mold size. At the same time, by changing the mold, you can get more styles of bath

bombs.

7.2 Automatic bath bombs labeling machine

Labels are very important for bath bombs. We can write company information and product information on the label, which is very helpful for brand promotion. However, manual labeling is very cumbersome, and we need a lot of manpower and material resources.