1. Symptom

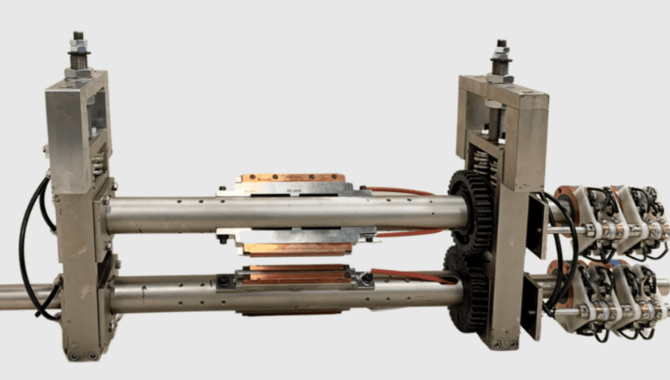

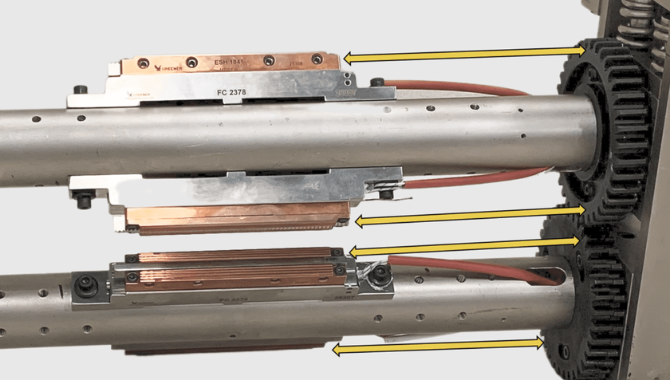

He installed many new parts on the nose, including shafts, bearings, springs and two pairs of sealing pliers. When he turned his jaws together with his hands, one pair of them meshed smoothly. But the second pair is too tight and requires extra effort to rotate.

2. Possible Reason

The set of old gears has been cleaned and reinstalled. Since only one pair of jaws are tight, he suspects that the gears are worn. But before checking them, he needs to make sure that the new components are not out of tolerance and cause discrepancies.

- The axis is consistent and true.

- If the new bearing is defective, the problem will occur intermittently. But in this case, the problem is the same.

- The two pairs of sealing pliers are new and proved to be the same design and height.

Easy to seal the telescopic jaw, quick replacement and insert

If he inspects the packaging on the customer’s packaging floor, he will make sure that a matching set of jaws is installed. Mixing new and used jaws or jaws with different zigzag patterns can cause problems.

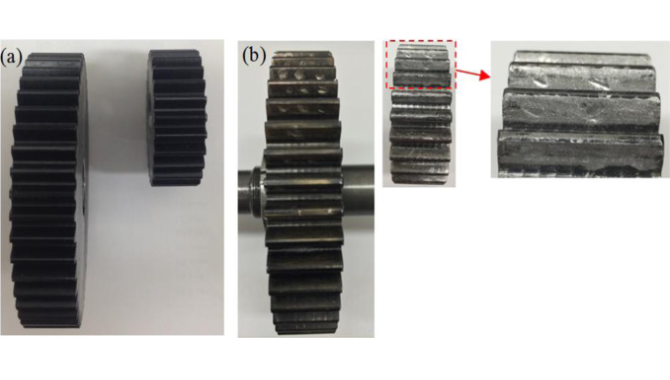

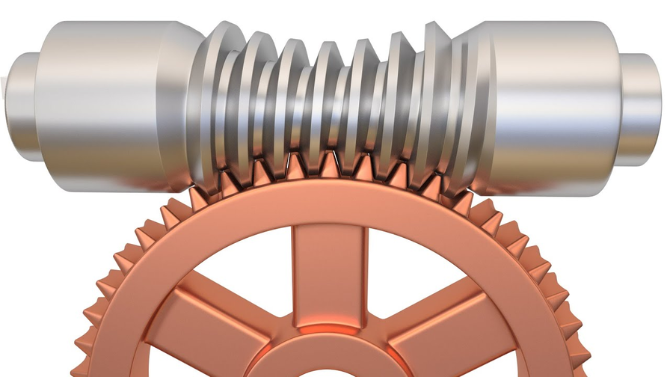

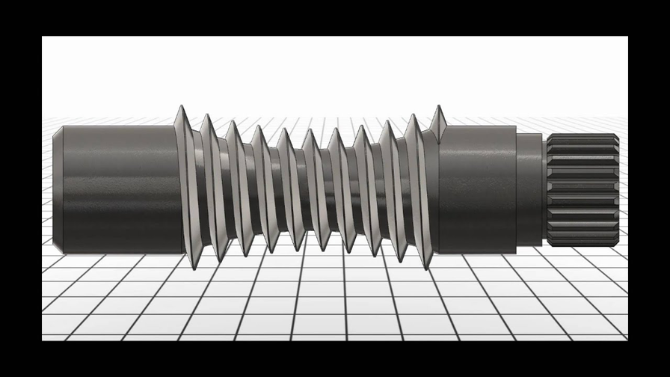

3. Uneven Gear Wear

More gear wear usually occurs on the meshing teeth because the sealing jaws come together.

This wear creates additional space between these gear teeth.

In the reconstructed head, the gears corresponding to one pair of jaws wear much more than the other pair. The split gear has been over-adjusted to remove the extra space between the most worn teeth. This makes the remaining gear teeth mesh too tightly when they pass through rotation.

4. Solution

This problem is solved when the worn gear is replaced with a new set of gears. The two pairs of jaws are aligned and meshed smoothly without any binding.

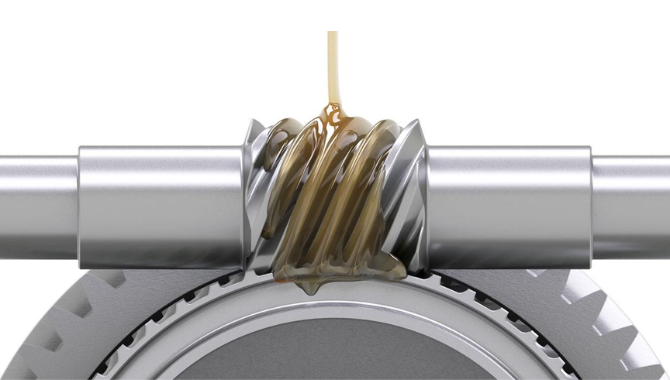

When you troubleshoot problems or perform regular maintenance on flow wrapping machine, be sure to check for excessive wear on the gears.