4 Side Seal Packaging Machine Manufacturer in China

JOCHAMP is a professional 4-side seal packaging machine manufacturer and a national high-tech enterprise, engaged in the research, development, sales, and service of packaging machinery. Dedicated to strict quality control and thoughtful customer service, our experienced staff members are always available to discuss your requirements and ensure full customer satisfaction.

- Intelligent auto-fault diagnosis function

- Highly corrosion-resistant, long-life

- Independent temperature control system

- Low noise operation (70 decibels within one meter)

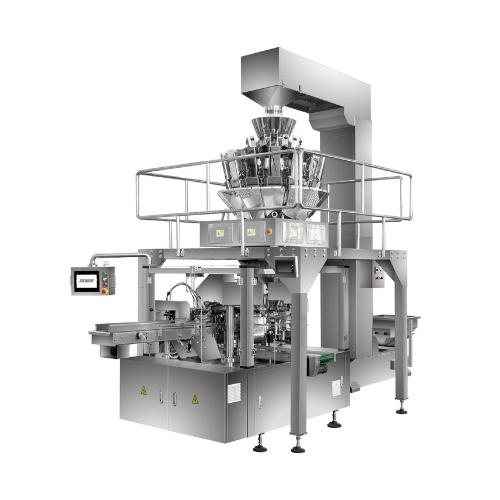

JOCHAMP 4 Side Seal Packaging Machine

The 4 side seal packaging machine is commonly used for sealing and packaging goods items. The entire machine body is built from the sturdiest stainless materials and sophisticated system controls, units, parts, and programs. JOCHAMP 4 side seal packaging machine gives a high-speed performance. It can withstand even massive and heavy-duty packaging — it works orderly and precisely, without worrying about any malfunctionality and troubles. This powerful machine is economical and capable of producing more than hundreds of finished products in a minute.

The marketing demand for the 4-side seal packaging machine remains high profile due to its usability, accessibility, and convenience in packaging production. Therefore, we, JOCHAMP, sum up with some ideas to innovate and develop the mechanical appearance and power capacity of the 4-side seal packaging machine into the most ideal and robust type.

Types of 4 Side Seal Packaging Machines

4 Side Seal Packaging Machine Advantages

JOCHAMP offers cutting-edge testing equipment and a highly skilled inspection team. Rest assured that all 4 side seal packaging machines are energy efficient and operate well.

The 4 side seal packaging machines are an excellent solution to enhance your productivity, whether you’re in the food, pharmaceutical, cosmetic, or other industries.

JOCHAMP machine, has simple operation, intuitive and convenient interface, complete function, steady performance, extended service life, and durability. Ideal machines for all seal packaging production.

The 4 side seal packing machines employ well-known brands and provide consistent performance and efficiency. GMP-compliant stainless steel of high quality and corrosion resistance.

4 Side Seal Packaging Machine Working Principle

The 4 side seal packaging machine consists of different parts and unit mechanisms that function altogether in their respective duties, that immensely contribute to the entire sealing process:

- Longitudinal Sealing Part. That is responsible for sealing the left side and right side of the products through a heating tube.

- Transverse Sealing Part. It is a reciprocating mechanism that seals packaging bags.

- Cutter Part. After the transverse sealing part, roll film will go through the punching part and cut off all finished products.

- Guiding and Rectifying Part. This part is used to direct the roll film and prevent it from deviation.

The entire sealing operation process is continuous and straightforward. After considering the fundamental procedures, formal production can be carried out.

High Innovated 4 Side Seal Packaging Machine

The 4 side seal packaging machine strictly follows the GMP requirements specification. This is a high-programed machine with automatic 4 side seedling, feeding, and easy tear punch controls. It adopts the advanced configuration and touch screen control for easy operation, adjustability, accuracy, and sustainable performance.

Due to fast development and sharp innovation for 4 side seal packaging machines, it has become the most in-demand sealing machine worldwide. It has unique qualities that have never been found in other machines, making it suited for products that require a high level of sealing, highly resistant, and aesthetically perfect.

4 Side Seal Packaging Machine Resource

JOCHAMP 4 side seal packaging machine is the most utilized sealing machine in the industry. It is perfect for sealing and packaging high-precision, regular or irregular, solid or liquid, granules or powdered and fragile items. Diverse sizes and volumes of products are accessible in the process.

Our 4 side seal packaging machines are classified into numerous categories and models, and each of them stands out due to its versatile features. It corresponds to the characteristics and needs required by the prestigious packaging industry. We ensure that our machine will deliver long-term interest, usability, convenience, and compatibility in the packaging line.

Why Choose JOCHAMP 4 Side Seal Packaging Machine

JOCHAMP is specialized in manufacturing a wide-ranging series of wrapping machines. We offer our 4 side seal packaging machine that, considers one of our company’s top-selling machines. For 15+ years, we have actively focused on research and development for 4 side seal packaging machines and providing a turnkey solution for all packaging sectors.

Furthermore, JOCHAMP adheres to sustainable development through our products. We provide high-quality 4 side seal packaging machines specified to our customers’ needs. As a top-notch manufacturer, we deliver on our promise to support any packaging business and project to the greatest extent.

Choose JOCHAMP innovation 4 side seal packaging machine now for the best packaging results.

JOCHAMP 4 side seal packaging machines have many unique features that make them worthy of any packaging and sealing production. Some of them are listed below for your reference:

- Lower power-energy consumption

- Intelligent temperature control

- Perfect automotive protective function

- Ensures precise and stable film feeding, material loading, and cutting

- Offers high precision and regular operation

- Manually or automatically operated

- Quickly detects and rejects a defective product

- Uses high programmed electrical, mechanical and pneumatic components

We offers 4 side sealing packaging machine that delivers enormous advantages, such as:

- Excellent sealing integrity and effect

- Flexible and able to run in an extensive range of packaging

- Time efficiency

- Completely validatable

- Advanced automation

- Stable and long-lasting circle

- Easy for installation and space-saving

- Applies advanced operating system

JOCHAMP 4 Side Seal Packaging Machine for Different Product Industry

The 4 side seal packaging machine for granular products, is suitable for packing free-flowing products such as sugar, salt, granular coffee, black pepper, etc. All the machines are of the highest standard in the market, as evident by the CE certificate as well as the strictly given ISO certification.

JOCHAMP continuous motion seal packaging machine is designed to fill liquid products such as ketchup, honey, mayonnaise, olive oils, shampoo, detergent, and other similar items. Our equipment can be customized from three to eight lanes. The fixed-width architecture and simplicity of the design enable efficient operation and utilization with simple features.

Non-free-flowing items, such as coffee cream, milk powder, instant soup, lemon powder, instant drink powder, flour, chili powder, medical powders, and so on, can be packed. A PLC system controls the machine, which has a huge touch screen. All of these innovative characteristics contribute to the machine’s stability and ease of operation, resulting in a great performance and minimum waste at a reasonable price.

Customers include large food, cosmetic, and pharmaceutical companies, who have used our four-sided seal packaging machines for liquid and paste products. To preserve the filled products, high weight precision, and seal integrity is required. This machine is simple but of great quality, and it is straightforward to operate.

Related Product

4 Side Seal Packaging Machine: The Ultimate Guide

Choosing highly efficient and reliable 4 side seal packaging machine requires a detailed understanding of features, working principle, parts, and classification criteria, amongst others. So if you want to learn more about 4 side seal packaging machine, read this guide.

4-side seal machine a type of packaging machine are that seals the product on all four sides.

Also known as four-side heat sealing machine, the equipment provides tamper-proof seals on product packaging bags, pouches and roll stock.

4 side seal packaging machine

4 Side Seal Machine is a versatile packaging equipment that allows you to minimize downtime and meet your growingly high production requirements.

4 side seal packing machine is purposed to pack solid and liquid products in sachet type packages. Many industries use the machine to pack the different products that include:

Pharmaceutical Industry

4 side sealing machines are used to pack various dosage forms such as tablets, capsules and other small tablets.

The machine is capable of sealing both sides of a tablet or capsule at once with a single operation. The product can be sealed in tamper-proof packaging material like foil or paperboard.

Food And Beverage Industry

The packaging equipment side sealing machines are used to pack various types of food items such as coffee and tea powder, ketchup, mayonnaise, mustard olive oil, among other products.

Cosmetic Industry

4 side seal packaging machines are used to pack various types of cosmetic products like soaps, shampoos, creams etc.

The tamper-proof packaging is perfect for this products, since they require a long shelf life due to their sensitive nature or aroma characteristics etc.

Moreover, the machine is also applicable to other industries such as petrochemical, electronic, chemical and other industries.

The machine has a unique design with automatic filling and sealing. Let’s explore the main components of the 4 side seal packaging machine:

parts of 4 side seal packaging machine

a. Feeder System: Supplies the packaging material, and only feeds out enough material for one pouch at a time.

By doing so, the feeder ensures that you do not have too much left over after sealing.

b. Rollers: Feed material through the machine and then wrap it around the product being packaged for proper sealing on all four sides.

c. Filling Head: The filling head is located at the top of the conveyor belt and injects product into the pouch.

It includes valves and cylinders used to fill products into the sachet.

d. Heat Sealing Head: Seals the material using heat so that it creates a tight seal around all four sides of the product being packaged.

There are two heat sealing heads in 4 side sealing machine:

- End Sealing Head: Used for top and bottom sealing of pouches and bags with a heat-sensitive adhesive.

There are different types of sealing heads like hot melt or hot air sealing head to meet different packaging requirements.

- Side Sealing Head: Helps in sealing the sachets longitudinally using heat or pressure sealing method.

e. Cutting Head: Uses blades that cut pouches into individual units when needed.

Also, it cuts off any excess material that might be left over after sealing the side flaps together.

f. Conveyor Belt: It is used to move the product from one location to another.

The filling mechanism is the most important part of any packaging machine.

It has to be designed in such a way that the product can be filled properly and uniformly into the package.

There are different types of filling mechanisms and we will discuss them in detail as follows:

Pneumatic Filler

Here, there is a pump attached with the filler which pushes the product into the package.

The product is injected via a nozzle attached at the end of filler tube.

These are most commonly used for liquid products like shampoo, milk, juices among others. Pneumatic filling is not suitable for powders because it may clog or block filler tubes if not cleaned properly after every cycle.

Consequently, this can lead to poor quality products.

Positive Displacement Pumps

The pump employs a simple principle of pumping liquid through a pipe by creating a vacuum at one end that draws in liquid.

Similarly, it creates pressure at the other end that propels the liquid out of the pipe.

Piston in this machine moves forward and backward while pushing a volume of liquid out of its chamber at each stroke.

During selection, the most common types of positive displacement pumps are centrifugal, volute rotary screw and vane pumps.

Each type has different advantages over others depending on their purpose, such as cost or efficiency.

Gravity Filling Mechanism

The gravity-fed filling mechanism works by using gravity to transport the product from the hopper to the filling head.

This type of mechanism has excellent accuracy but it can be slow due to its reliance on gravity to move the product through it.

Therefore, it is suitable for low viscous products like viscous liquids, powders, granules or tablets.

There are a number of different ways of sealing in 4 side seal packaging machine, depending on the packaging material being used:

Heat Sealing

Heat sealers use heat to form a bond between two pieces of material.

The system applies an adhesive tape or glue on one side of the sealer before placing it on the packaging material with no adhesive.

The glue or tape melts when heated, bonding both sides together with an airtight seal.

Some heat sealers can be used with different types of materials such as paper and plastic film (PP). Others may only be used with one type such as polypropylene (PP) film only or polyethylene (PE) film only.

Cold Sealing

These type of sealing mechanism also use heat. However, instead they use cold temperatures to form an airtight seal without melting down completely like in hot sealing.

Mechanical Sealing

In mechanical sealing the seal is formed by means of an elastic material or a rubber.

The material is pressed against the sides of the package by means of a moving blade or roller.

A variation on this type of seal is called “mechanical press” and uses pressure to form the seal rather than a sharp edge.

Vacuum Sealing

Vacuum sealing machines use vacuum to pull two pieces together and form a seal around them.

The sealer head applies heat and/or pressure simultaneously while they are held tightly together against opposing surfaces inside an airtight chamber.

Operation of 4 side seal packing machine involve the following main steps:

Step One: Film Roll Feeding

The film is fed to the front and back of the machine via tension control rollers. If different films are utilized, two rolls will be supplied.

If the same film is used on both sides, it is common to supply one, wide roll of film. As the film comes off the roll, it is cut in half.

The two halves of the film are guided to the machine’s front and rear.

Step two: Sealing

Subsequently, the films are joined and passed through a pair of rollers that form the longitudinal, lengthwise seal between the pouches.

To compensate for any minor misalignments, a small amount of material is usually trimmed from the joined film’s outer edges.

The cross seal is formed by a second sealing roll below, which seals the bottom of the current pouch and the top of the preceding pouch.

Rather than a flat surface, these rolls are typically designed with cavities.

The design allows them to conform to the shape of the product or to make room for it.

Step Three: Product Feeding

The pouch is now formed on three sides, and you can introduce the product.

To dispense the product into the pouch, you can use various types filling pumps (liquids) or feeders (solid).

Nitrogen or another gas can be injected at this point if necessary.

It is critical to avoid getting powder or liquid on the seal area, as this will interfere with proper sealing.

Step Four: Cutting

As the pouches move through the equipment, they are cut longitudinally into strips. Using a cross cutter, the strips are slit into separate pouches.

Step Five: Printing:

Here, the 4 side seal packaging machine prints data matrix text and barcode using thermos transfer, laser or ink.

Step Six: Inspection

Integrated vision inspection system of the packaging verifies the OCR print, product presence and position, with any non-conforming packs being rejected automatically.

Step Seven: Discharge

Finally, the 4 side sealing packing machine discharges the conforming packs for onward manual or automatic processing.

4 side seal packaging machine has many advantages over other packaging machines:

Easy to Operate

The machine is very easy to use and you do not require any technical knowledge to operate it. Because of its design, even operators who are not familiar with technology can easily operate this machine without any difficulty at all.

Highly Efficient

The 4 side seal packaging machine offers high efficiency in its operations and also helps in reducing production time and cost.

Increased Production

Investing in the equipment will boost your productivity. Therefore, there will be no loss of profit even if there is an increase in production rate or demand.

Reduced Wastage

The 4 side seal packaging machine reduces wastage by providing tight seals on all sides of the product being packed.

This is done so that air does not enter inside and no leakage takes place during transportation or storage of products till they reach their destination.

This improves customer satisfaction level thereby increasing sales volume for the company having this

When ordering for the equipment, consider the following key technical specifications of 4 side seal packaging machine:

- Filling System

- Bag Dimensions

- Production Speed

- Motor Power

- Heater Power

- Voltage

- Application

There are many different types of four side sealing machine available in the market. Here are the main ones that you should consider during selection:

Multilane 4 Side Seal Packaging Machine

As the name suggests, this packaging equipment features multiple tracks, ranging from 2 to 12 tracks.

With the machine, you can have a web width as much as 32 inches wide.

Multilane 4 side sealing machine is ideal for packaging liquid and paste products within workable viscosity limit.

You can also use it for non-free flowing and free flowing powders.

multilane 4 side seal packaging machine

4 Seal Side Sachet Packaging Machines

Automatic 4 side seal sachet packaging machine prod rectangular or square sachet packets.

Fitted with a PLC system, you can manufacture between 100 to 120 sachets every minute.

The size of packs produced are adjustable, and the equipment allows you to package liquid paste, non-free flowing and free flowing products.

4seal side sachet packaging machine

4 Sides Sealing Sachet Form Filling Sealing Machine

Here, the machine forms the pack, fills it with dry or dry items and seals it tight.

Most 4 side form fill sealing machines utilize flexible film to create the primary package like pouch or bag.

Also, majority of 4 side FFS equipment use heat sealing as the preferred technique of forming an airtight package.

4 sides sealing sachet form filling machine

There are two main types of the packaging machine:

4 Side Horizontal Form Fill Seal Machine

Four side Horizontal Form-Fill-Seal machines require more floor space but are ideal for high-speed packaging applications.

They enable manufacturers to create a variety of pouch shapes and are ideal for packaging foods, cosmetics, chemicals, pharmaceuticals, and pet foods.

4 side horizontal form fill seal machine

4 Side Vertical Form Fill Seal Machine

Four side Vertical Form-Fill-Seal Machines are optimal for limited floor space and regular packaging adjustments.

Their simplified design makes them easier and quicker to clean, assuming they are constructed to the highest sanitary standards.

The primary distinctions between the two 4 side FFS machine types are bag complexity, speed, and to a lesser extent, bag finish.

4 side vertical form fill seal machine

While there are many similarities between the bag types produced by each technology, some are more efficiently produced by a particular machine type.

The majority of four-side seal packaging machines are designed and built for seamless integration into an existing production or packaging line.

Automated 4 side sealing machines can be integrated into production line to increase efficiency, satisfy demand and reduce costs over time.

Additionally, they minimize downtime caused by malfunctioning machinery or recalibration when working with different built systems .

This leads to needing different sanitization and cleaning procedures.

The following are troubleshooting tips for 4 side seal packing machine that you can follow in case you encounter an issue:

i. Sealer not sealing properly or sealing at all: Check if the seal bar is lined up with the seal plate and make sure the pinch wheel is not under any pressure.

ii. No power: Check if the power cord has been plugged in and make sure there is no obstruction in between that could cause a short circuit.

iii. Sealing bar does not move up and down: Check if the drive belt has been correctly placed on top of the motor pulley.

If it has been removed from its position, then you need to reattach it before trying again.

iv. Machine keeps breaking down or shutting down automatically: This happens when too much pressure is being applied by too many items being packed per cycle.

v. Machine keeps jamming and not working at all or not sealing properly: The most common cause is that there are no products left in the feeder.

Make sure there are enough products in the feeder system before starting up again after a jam.

If the problems persist, then you will probably have to stop and clear out any remaining product manually before restarting again.

For all your 4 side seal packaging machines, contact u snow.